Changeovers in manufacturing are a critical aspect of production processes. They can significantly impact efficiency, productivity, and overall operational excellence. In this context, FAT FINGER, a digital workflow procedure builder, plays a pivotal role. It empowers front-line teams to perform their work correctly every time by facilitating seamless line changeovers. With FAT FINGER, you can build digital workflow procedures that unlock operational excellence, reduce downtime, improve line efficiency, and increase product quality.

Understanding Changeovers in Manufacturing

Changeovers in manufacturing refer to the process of switching from producing one product to another. This process involves several steps, including clearing the line, cleaning the line, and inspecting the line. These steps are crucial to prevent cross-contamination of products, ensure the cleanliness of the production line, and verify that all equipment is in good working order.

Types of Changeovers in Manufacturing

There are primarily two types of changeovers in manufacturing:

- Internal Changeover: This type of changeover involves activities that can only be performed when the production line is stopped. It includes tasks such as replacing machine parts or adjusting machine settings.

- External Changeover: This type of changeover involves activities that can be performed while the production line is still running. It includes tasks such as preparing the next set of materials or tools.

Impact of Changeovers in Manufacturing

Changeovers can have a significant impact on manufacturing processes. They can affect production time, product quality, and overall operational efficiency. For instance, a poorly managed changeover can lead to extended downtime, reduced productivity, and increased waste. On the other hand, a well-managed changeover can enhance efficiency, improve product quality, and boost profitability.

Role of FAT FINGER in Facilitating Changeovers

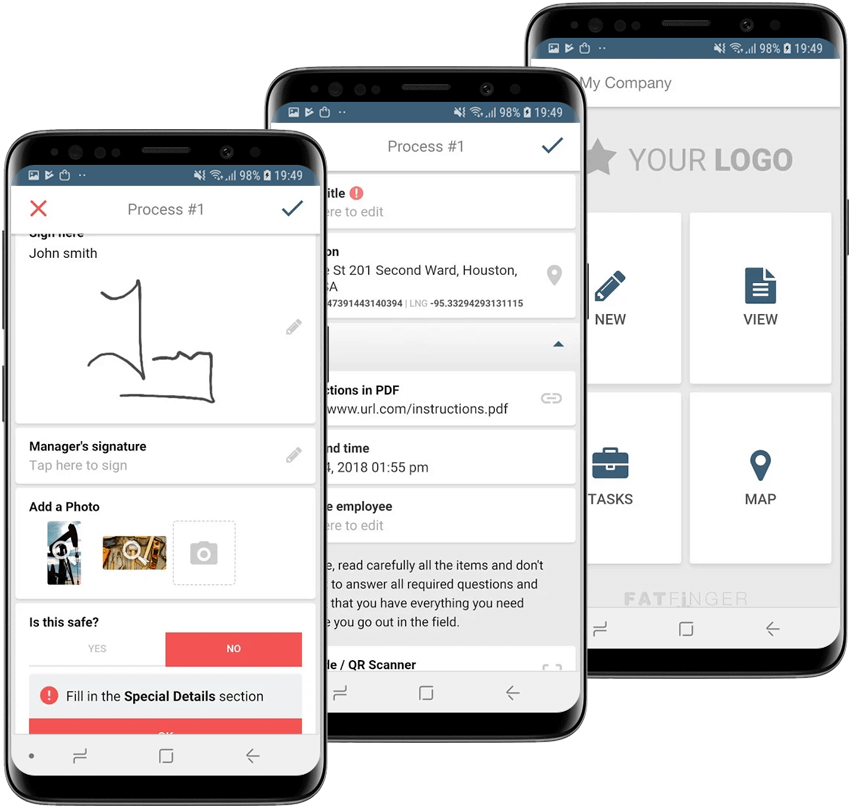

FAT FINGER plays a crucial role in facilitating changeovers in manufacturing. It allows you to build digital workflow procedures that streamline the changeover process. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER ensures that your line changeovers are smooth and efficient.

Benefits of Using FAT FINGER for Changeovers

Using FAT FINGER for changeovers in manufacturing offers several benefits:

- Reduced Downtime: By streamlining the changeover process, FAT FINGER helps to minimize downtime and enhance productivity.

- Improved Efficiency: FAT FINGER allows you to create digital workflow procedures that ensure all changeover activities are performed correctly and efficiently.

- Increased Product Quality: By ensuring that all line changeover activities are completed, FAT FINGER helps to prevent cross-contamination of products and ensure product quality.

Conclusion

In conclusion, changeovers in manufacturing are a critical aspect of production processes. They can significantly impact efficiency, productivity, and overall operational excellence. FAT FINGER, with its advanced features and capabilities, plays a pivotal role in facilitating seamless line changeovers. By using FAT FINGER, manufacturers can reduce downtime, improve line efficiency, and increase product quality.

Ready to experience the benefits of seamless line changeovers? Sign up to create a line changeover workflow for free on FAT FINGER or schedule a demo today!

Discover the different types of changeovers in manufacturing and their impact on efficiency and productivity. Learn how to optimize your processes and reduce downtime. Don’t miss out on this opportunity to improve your operations. Schedule a demo today to see these strategies in action.