A Job Hazard Analysis (JHA) Risk Matrix is a valuable tool used in high-risk industries such as manufacturing, energy, mining, and the oil and gas industry to systematically assess and mitigate workplace hazards.

These industries are particularly susceptible to various risks, including physical, chemical, ergonomic, and environmental hazards. Here’s an elaboration on how a JHA risk matrix can be used, its benefits, and how to conduct one:

Benefits of A Job Hazard Analysis (JHA) Risk Matrix

High-risk industries can benefit significantly in the following ways from using a JHA Risk Matrix:

Enhanced Safety: By systematically identifying and addressing hazards, organizations can reduce the occurrence of accidents and injuries, improving overall workplace safety.

Regulatory Compliance: Many high-risk industries are subject to strict safety regulations. A JHA Risk Matrix can help ensure compliance with these regulations by proactively addressing potential issues.

Cost Reduction: Preventing accidents and injuries can lead to reduced workers’ compensation claims and associated costs, as well as potential savings in insurance premiums.

Improved Training: The JHA process also highlights the need for specific training and skill development for employees to handle potential risks, enhancing their overall competence.

Types of Job Hazard Analysis (JHA) Risk Matrices

There are different types of Job Hazard Analysis (JHA) risk matrices, each with its own approach to categorizing and assessing risks. Here are a few common types:

Severity and Probability Matrix:

This is one of the most common types of risk matrices. It assesses risks based on two main factors:

- The severity of the potential harm (e.g., minor injury, major injury, fatality)

- The probability of the hazard occurring (e.g., rare, occasional, frequent).

The intersection of severity and probability provides the following risk ratings.

- Low Severity, Low Probability: Low-risk issues that may not require immediate attention.

- High Severity, Low Probability: High-risk issues that should be addressed to prevent severe consequences.

- Low Severity, High Probability: High-risk issues that occur frequently but may not result in severe harm.

Risk Priority Number (RPN) Matrix

Risk Priority Number (RPN) is a numerical ranking system used in various industries, especially in quality management and risk assessment, to prioritize and manage risks associated with products, processes, or projects.

It’s often used in the following contexts:

- Failure Modes and Effects Analysis (FMEA)

- Failure Modes, Effects, and Criticality Analysis (FMECA).

RPN helps organizations identify and focus on high-priority issues that could have a significant impact on the quality, safety, or performance of their products or processes.

This matrix combines severity, probability, and detection ratings to calculate a Risk Priority Number for each hazard.

It helps prioritize hazards based on their potential impact and the likelihood of detection.

RPN = Severity × Probability × Detection

A higher RPN indicates a higher-priority hazard.

Once you have defined the severity and likelihood scales, you can assess each hazard associated with a specific job task or activity and plot it on the matrix.

Once you have defined the severity and likelihood scales, you can assess each hazard associated with a specific job task or activity and plot it on the matrix.

The risk score at the intersection of the severity and likelihood ratings will determine the priority for addressing that hazard:

Low Risk: Hazards in the bottom left corner (e.g., S1, L1) are considered low risk and may require minimal attention.

Moderate Risk: Hazards in the middle area of the matrix may require further evaluation and control measures.

High Risk: Hazards in the upper right corner (e.g., S4, L5) are high-risk hazards that should be a top priority for mitigation.

Final Words: Which Risk Matrix Should You Use?

The specific scales and criteria used in a JHA risk matrix may vary between organizations and industries, so it’s important to adapt them to your specific needs and regulations.

But bear in mind that the JHA risk matrix you choose should help your organization:

- Allocate resources and prioritize safety efforts effectively.

- Communicate risk to employees and stakeholders

- Ensure that everyone understands the level of risk associated with different tasks and activities in the workplace.

Build Your Risk Analysis Matrix with FAT FINGER

A Job Hazard Analysis (JHA) Risk Matrix is a valuable tool used in high-risk industries such as manufacturing, energy, mining, and the oil and gas industry to systematically assess and mitigate workplace hazards.

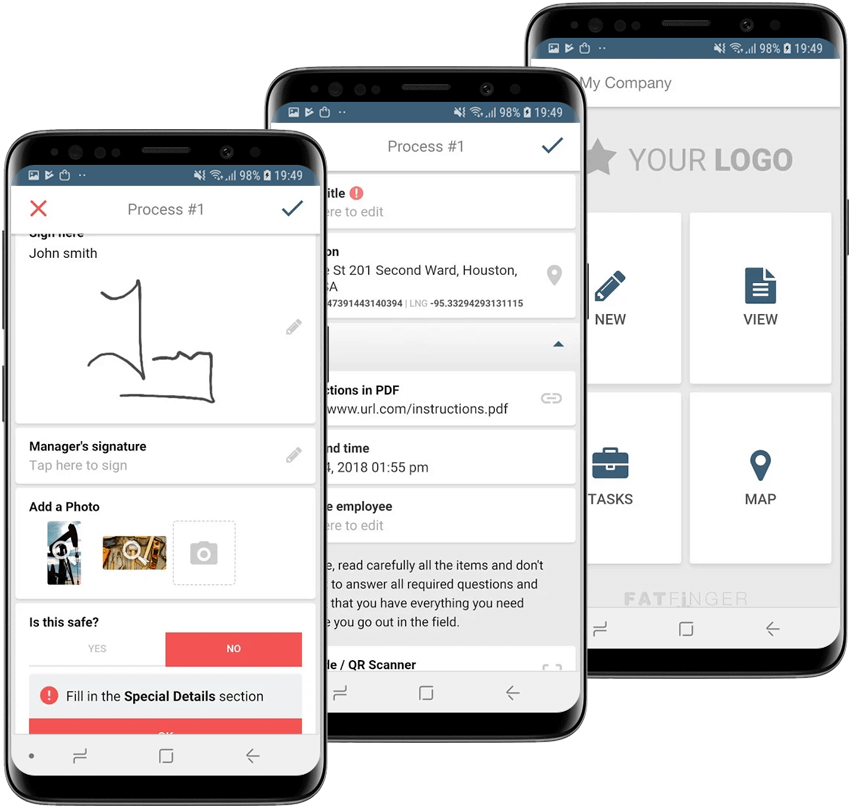

Software like FAT FINGER makes building a Job Hazard Analysis (JHA) Risk Matrix hassle-free, further enhancing workplace safety.

FAT FINGER offers:

An easy-to-use interface: Workers can promptly and accurately document testing through an easy-to-use interface even in high-pressure industrial environments, ensuring accuracy and efficiency.

Data-Driven Insights: The software compiles risk analysis data to generate comprehensive reports and visualizations, empowering organizations to make informed decisions.

Integrated Workflows: FAT FINGER seamlessly integrates incident reporting into existing industrial workflows, ensuring a cohesive approach to safety and operational excellence.