Visual work instructions are a powerful way to communicate standard work practices. Their clear and concise visuals make it easy for users to understand what they need to do and how the final product should look.

Visual work instructions templates can be used in many different settings, such as quality management, machine operation, etc.

Table of Contents:

1. Visual Work Instruction and Its Importance in Lean Manufacturing

2. Disadvantages of Using Paper-based Visual Work Instruction

3. How Can VWIs be Used in Different Settings?

4. 3 Tips on How to Create Great Visual Work Instruction

5. Advantages of Using a Digital Work Instruction with FAT FINGER

Visual Work Instruction and Its Importance in Lean Manufacturing

In lean manufacturing, visual work instructions (VWI) are vital for creating a continuous flow of value-added activity and eliminating waste. Rather than using extensive written documents that can be difficult to follow, VWI uses pictures and symbols to depict the steps in a process. This makes it easy for workers to understand what they need to do and also makes it easier to identify potential sources of error or waste.

There are many benefits to using visual work instructions on the shop floor. First, they can dramatically reduce the time needed to train new workers, as the pictorial format makes it easier to grasp the information than text alone. Second, visual work instructions can improve communication between workers and supervisors, as it is easy to see whether a worker is following the correct procedure. Finally, visual work instructions can help to reduce variability in how a task is performed, as everyone can easily see the standard way of doing things.

While visual work instructions have many advantages, they are not without challenges. One challenge is that they can be time-consuming to create, mainly if a process is complex or constantly changing. Another challenge is that VWI may need to be accompanied by more detailed written instructions if workers are not familiar with the symbols used. Despite these challenges, visual work instructions can be a powerful tool for promoting lean manufacturing principles on the shop floor using current digital technology.

Disadvantages of Using Paper-based Visual Work Instruction

There’s no denying that visual work instructions are an essential part of any manufacturing or assembly process. They provide clear, step-by-step guidance that can help workers to complete tasks quickly and accurately. However, paper-based visual work instructions can present several challenges.

1. One of the biggest challenges is ensuring that the instructions are always up-to-date. It can be difficult to keep track of all the different versions of a paper document. If the process changes, new versions of the VWI must be printed and distributed. This can be time-consuming and expensive, and there is always the risk that outdated instructions will be used.

2. Paper visual work instructions is that they are static. Once they are printed, they cannot be changed or updated without going through the entire printing and distribution process again. This can lead to outdated documents being used, which can cause errors and confusion.

3.Paper-based VWI can be challenging to read in low-light conditions or when they become wet or dirty. This is a crucial point since various manufacturing conditions also require different types of environments.

With all of these challenges, many industries are transitioning to implement visual work instructions in form of digital templates.

How Can VWIs be Used in Different Settings?

Visual work instructions can be used in different settings to help workers perform tasks more effectively. May it be for manufacturing, industrial settings, or quality management, visual work instructions provide clear and concise step-by-step guidance.

Manufacturing. Visual work instructions can be used to standardize processes and ensure quality. One of the key benefits of visual work instructions is that they can help to support lean manufacturing principles. Lean manufacturing is all about maximizing value while minimizing waste, and visual work instructions can play a role in achieving these objectives.

For example, by eliminating the need for worker training on complex procedures, visual work instructions can help to reduce manufacturing cycle times. In addition, by identifying potential problems early in the process, visual work instructions can help prevent errors and defects from occurring later on down the line.

Industrial setting. Visual work instructions can be used to communicate safety procedures. VWI can help reduce the need for verbal communication on the shop floor, decreasing the chances of miscommunication and mistakes.

Quality Management. Visual work instructions can be used to track and improve process performance. Providing clear and concise visual guidelines can help employees achieve consistent results and minimize errors. In addition, visual work instructions can be used to create samples of acceptable finished products.

The applications of visual work instructions are limited only by the user’s imagination. With a bit of creativity, they can be adapted to nearly any setting. By leveraging the power of visual communication, industries can unlock new levels of efficiency and productivity.

3 Tips on How to Create Great Visual Work Instruction

Creating visual work instructions can be challenging, but there are a few essential tips to keep in mind to ensure they are effective.

1. Think about the audience. What level of detail do they need to understand and complete the task? Too much detail can overwhelm the instruction, while too little can leave them confused. For example, someone new to a task will need more step-by-step guidance than someone experienced. In addition, viewers from different cultural backgrounds may have other preferences in terms of the level of detail provided in the VWI.

2. Use clear and concise language. The instructions should be easy to understand and follow, without ambiguity or confusion. Visual work instructions are designed to be read and understood quickly by workers who may not be familiar with the task at hand. If the language is too technical or overly complicated, it can create confusion and lead to errors. Using clear and concise language, visual work instructions can help ensure that workers have a common understanding of the task at hand and can complete it accurately and efficiently.

3.Use instructional design principles.

This includes using visuals to support the text, breaking the task down into small steps, and using labeling and color-coding to improve clarity. Adding actual photos of the task being performed can be helpful, but ensure they are high quality and easy to understand. Visual cues can help draw attention to the most essential parts of your instructions.

By following these tips, it is possible to create visual work instructions that are clear, concise, and easy to follow.

Advantages of Using a Digital Work Instruction with FAT FINGER

The Harvard Business Review conducted a study last 2017 to evaluate the impact of smart glasses and AR on performance and productivity. A GE technician is shown in the study executing a task with traditional instruction manuals and then the same task again with line-of-sight instructions on digital smart glasses.

The study found that the digital device improved the worker’s performance by 34 percent on first use.

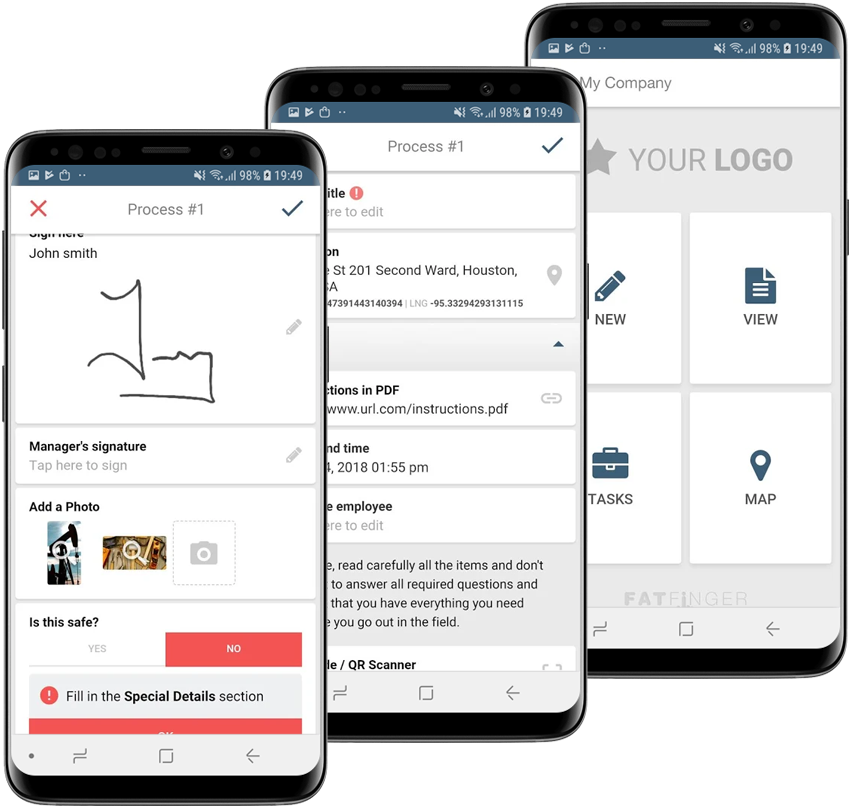

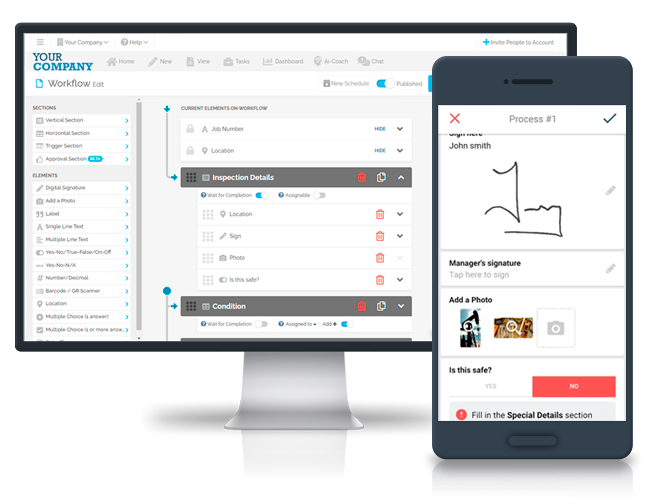

FAT FINGER digital visual work instruction is a digital workflow that provides step-by-step instructions for completing a task. Unlike a traditional paper instruction, a digital visual work instruction can be easily updated and shared with other workers. As a result, it can help to improve efficiency and reduce mistakes. Here are three primary advantages of using FAT FINGER digital visual work instruction:

-Digital visual work instruction can be easily updated as processes change. This is important in today’s ever-changing business environment, where new technologies and methods are constantly being introduced. By using a digital visual work instruction, businesses can ensure that their workers always have the most up-to-date information.

-Digital visual work instruction can be easily shared with other workers. This is particularly helpful when multiple workers are involved in completing a task. By sharing the digital visual work instruction, businesses can ensure that everyone is on the same page and working towards the same goal.

-Digital visual work instruction can help to reduce mistakes. By providing clear and concise instructions, industries can help their workers avoid misunderstandings and errors. In some cases, industries may even be able to eliminate training costs by using a digital visual work instruction.

Overall, there are many advantages to using a digital visual work instruction. By leveraging the latest technology, businesses can improve efficiency and avoid mistakes.

Looking for a better way to complete tasks? Do you spend too much time reading and re-reading paper instructions?

FAT FINGER is the answer. It provides step-by-step digital visual work instructions that are easy to follow and can be updated as needed. As a result, you can avoid mistakes and improve efficiency.

Imagine completing tasks with ease and confidence, knowing that you have the most up-to-date instructions at your fingertips. With FAT FINGER, that’s exactly what you can expect. This innovative tool will change the way you work – for the better.

Try FAT FINGER today – it’s free to download!

About FAT FINGER:

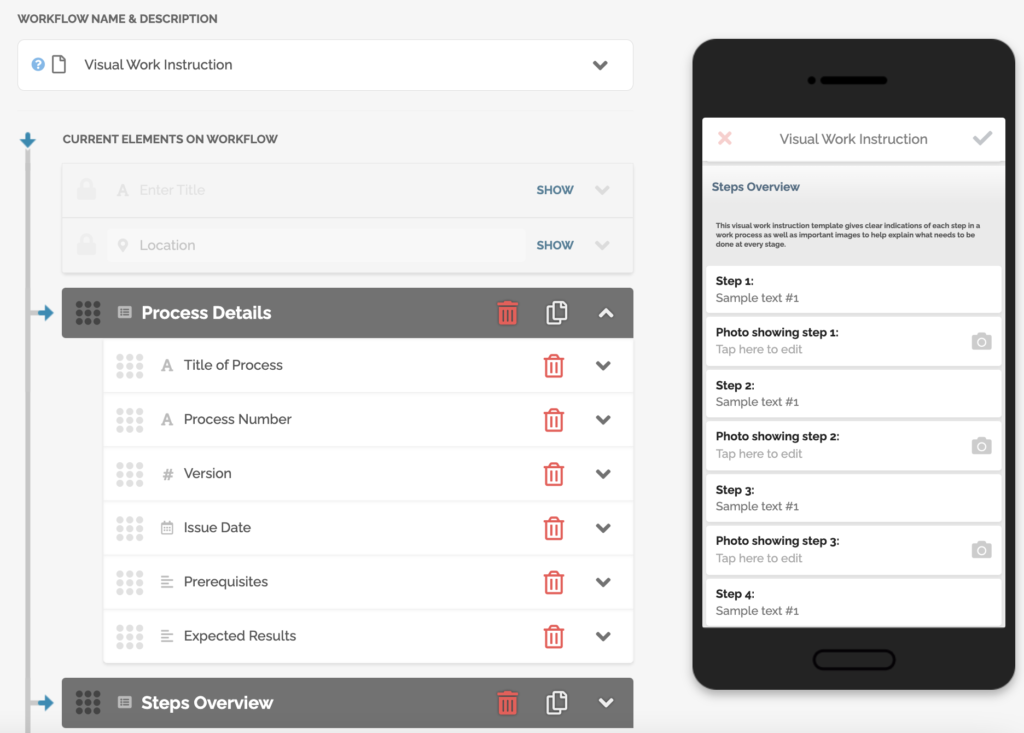

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.Try building your digital procedure on FAT FINGER for free @www.fatfinger.io

Build and customize your visual work instruction in seconds

Every site has its own potential hazards. In FAT FINGER you will be able to import different visual work instructions and make them your own, or simply create one from scratch. And once you are done, you will be able to export your work instruction workflow to all of your different sites.

FAT FINGER is a work instruction tool

FAT FINGER is the right place where to do all your work instruction before performing any tasks out in the field. And also allows any employee to share information in real-time with the entire team, such as photos of a potential hazard.