As we navigate the digital age, the future of asset management is being reshaped by innovative technologies. One such technology is Predictive Maintenance, a game-changing approach that is transforming industries across the globe. This article will delve into the world of Predictive Maintenance, its benefits, and how it is revolutionizing asset management. We will also introduce you to FAT FINGER, a digital workflow procedure builder that is at the forefront of this transformation.

What is Predictive Maintenance?

Predictive Maintenance is an engineer’s best friend and a powerful tool for optimizing platforms in a manufacturing facility. Instead of having scheduled maintenance done on a predetermined timeframe, Predictive Maintenance uses data and technology to specify when maintenance needs to be completed to prevent costly breakdowns accurately. It works by collecting data from a facility’s various components and then using it to determine when parts need maintenance, as well as use algorithms or Artificial Intelligence (AI), if necessary.

The Role of FAT FINGER in Predictive Maintenance

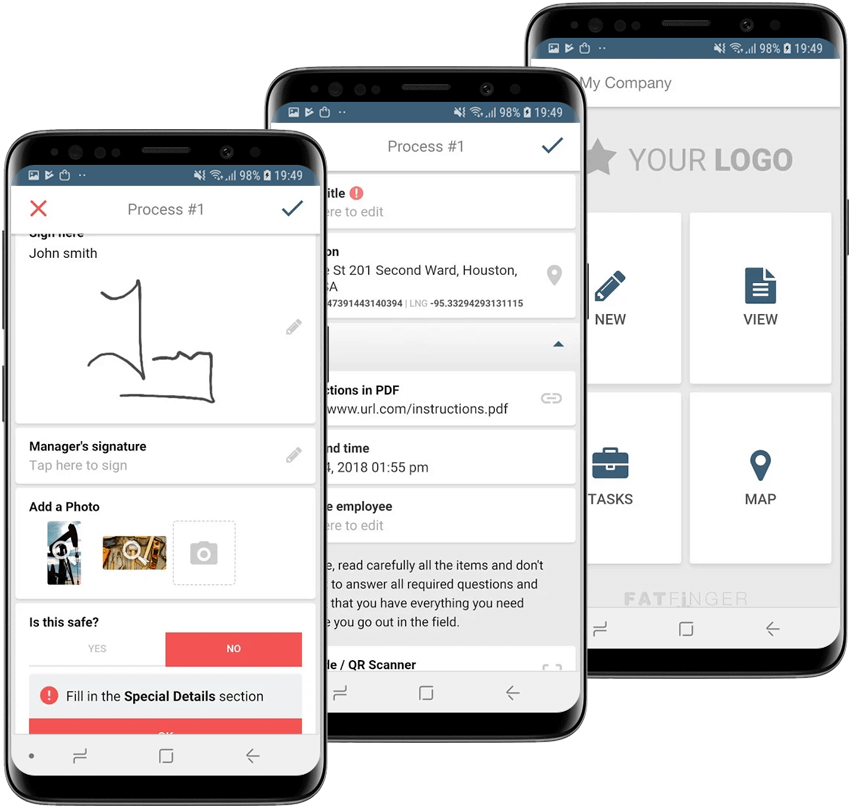

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is a powerful tool in the Predictive Maintenance landscape. You can build Predictive Maintenance digital workflows to ensure problems are gone even before they start.

Benefits of Predictive Maintenance

- Cost Savings: Predictive Maintenance can help save time and money by preventing costly breakdowns and reducing downtime.

- Improved Efficiency: By predicting when maintenance needs to be done, Predictive Maintenance can improve efficiency in the facility.

- Safety Standards: Predictive Maintenance can help ensure that safety standards are adhered to throughout the lifecycle of all machines.

Case Studies: Predictive Maintenance in Action

Several industries have already started reaping the benefits of Predictive Maintenance. For instance, in the aviation industry, Predictive Maintenance is used to monitor aircraft components and predict potential failures before they occur. This not only improves safety but also reduces downtime and maintenance costs.

In the manufacturing sector, Predictive Maintenance is used to monitor machinery and equipment to predict and prevent failures. This results in increased operational efficiency and reduced maintenance costs.

Conclusion

The future of asset management is here, and it is being shaped by Predictive Maintenance. By leveraging data and technology, Predictive Maintenance is transforming industries by improving efficiency, reducing costs, and ensuring safety standards. With tools like FAT FINGER, implementing Predictive Maintenance has never been easier.

Ready to take the leap into the future of asset management? Schedule a demo with FAT FINGER today or create a predictive maintenance workflow for free and see how Predictive Maintenance can transform your operations.

Discover the future of asset management and how predictive maintenance is transforming industries. Learn more about these revolutionary changes and how they can benefit your business. Don’t miss out on this opportunity to stay ahead of the curve. Schedule a Demo today.