Artificial Intelligence (AI) is revolutionizing various industries, and one area where its impact is significantly felt is in the material inspection processes. Companies like FAT FINGER are at the forefront of this revolution, leveraging AI to empower front-line teams to perform their work correctly every time. This article explores how AI is improving material inspection processes and how FAT FINGER’s digital workflow procedure builder is playing a crucial role in this transformation.

AI in Material Inspection: A Game Changer

AI has brought about a paradigm shift in material inspection processes. It has made inspections faster, more accurate, and less prone to human error. Here are some ways AI is improving these processes:

- Automated Defect Detection: AI can identify defects that might be missed by the human eye, reducing the risk of faulty products reaching the market.

- Improved Accuracy: AI algorithms can analyze data with a level of precision that surpasses human capabilities, leading to more accurate inspection results.

- Increased Efficiency: AI can process large volumes of data quickly, speeding up inspection times and increasing overall productivity.

FAT FINGER: Harnessing the Power of AI

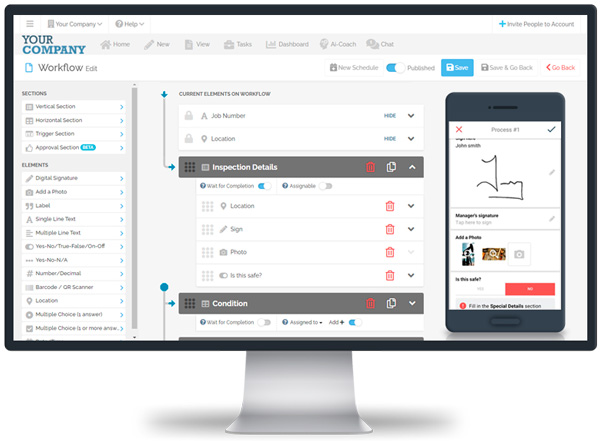

FAT FINGER is a digital workflow procedure builder that uses AI to improve material inspection processes. It allows teams to build checklists, workflows, and digital procedures that unlock operational excellence. Here’s how FAT FINGER is using AI to enhance material inspection:

- Drag & Drop Workflow Builder: This feature allows teams to create custom workflows for material inspection, ensuring that all necessary steps are followed.

- Mobile & Desktop Workflows: FAT FINGER’s workflows can be accessed on both mobile and desktop devices, allowing for inspections to be conducted anywhere, anytime.

- Artificial Intelligence Coaching: FAT FINGER’s AI coaching provides real-time guidance to teams, helping them perform inspections more effectively and efficiently.

Case Study: AI in Action

A case study that illustrates the impact of AI on material inspection processes involves a manufacturing company that implemented FAT FINGER’s AI-powered solutions. The company was able to reduce its defect rate by 30%, increase its inspection speed by 50%, and improve its overall productivity by 20%. This case study demonstrates the transformative potential of AI in material inspection processes.

Conclusion

AI is revolutionizing material inspection processes, making them faster, more accurate, and more efficient. Companies like FAT FINGER are leading this revolution, leveraging AI to empower front-line teams and unlock operational excellence. With AI, the future of material inspection looks brighter than ever.

Are you ready to harness the power of AI in your material inspection processes?

Discover how Artificial Intelligence is revolutionizing material inspection processes, enhancing accuracy and efficiency. Learn more about these advancements and how they can benefit your business. Visit FAT FINGER today to explore the potential of AI in material inspection.