In production and manufacturing, the significance of raw material inspection cannot be overstated. Ensuring the quality and integrity of incoming materials lays the foundation for a seamless production process, fostering efficiency and excellence.

This comprehensive guide delves into the intricacies of conducting a thorough raw material inspection, providing you with a roadmap for success.

Step 1: Setting the Stage for Success. Sign up for FAT FINGER

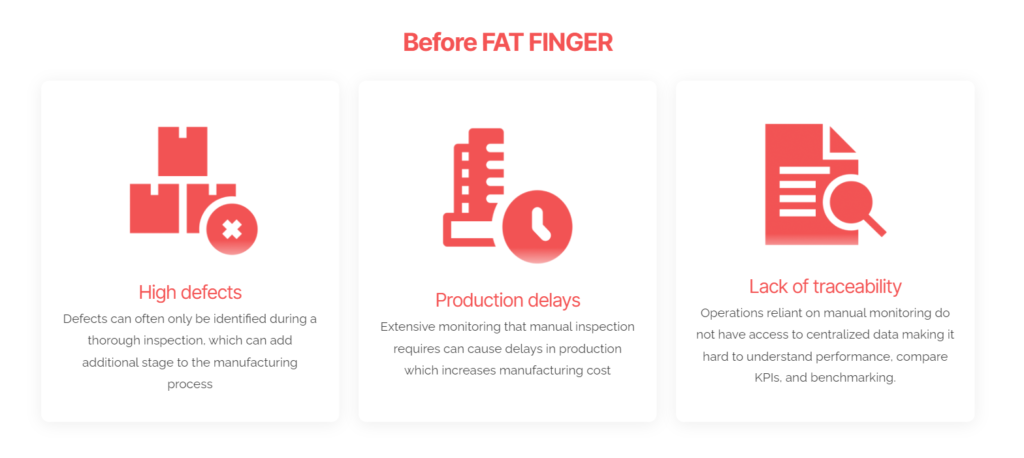

Successful inspection begins with the right tool. FAT FINGER, an easy to use, no-code, drag-and-drop app, enables you to build digital procedures to make inspections easier. Below are reasons for integrating FAT FINGER into your material inspection and testing processes:

Intuitive Digital Workflows

Say goodbye to cumbersome paper-based processes. FAT FINGER empowers you to design and implement intuitive digital workflows tailored to your unique inspection requirements. Drag-and-drop functionality allows for the seamless creation of inspection procedures, ensuring a user-friendly experience for your inspection team.

Real-Time Collaboration

Efficiency thrives on collaboration, and FAT FINGER facilitates just that. With its real-time collaboration features, teams can work cohesively on inspection procedures, share insights, and adapt workflows on the fly. This real-time interaction minimizes delays, expediting the inspection process without compromising precision.

Tailoring Inspection Forms

Customization is critical in raw material inspection. FAT FINGER’s no-code configuration empowers you to tailor inspection forms without complex coding. Whether it’s capturing specific data points or integrating industry-specific criteria, this tool puts the power of customization in your hands.

Adaptable to Varied Testing Methods

Material testing comes in diverse forms, and FAT FINGER acknowledges this variability. From visual inspections to advanced spectroscopic analyses, the platform’s no-code configuration supports incorporating various testing methods. This adaptability ensures that your inspection procedures align precisely with the nature of the materials being examined.

Enhancing Data Accuracy and Accessibility

FAT FINGER enables digital data to be captured directly from the inspection site, reduces the likelihood of mistakes, and accelerates the data collection, ensuring that your records are accurate and available in real-time.

Analytics for Informed Decision-Making

Transforming raw data into actionable insights is a hallmark of excellence. FAT FINGER’s analytics tools empower you to derive meaningful conclusions from inspection data. By leveraging these insights, you can make informed decisions, identify trends, and drive proactive improvements in your material inspection processes.

Continuous improvement

Continuous improvement relies on timely feedback. FAT FINGER’s capability to provide instant feedback loops facilitates the seamless exchange of insights between inspectors and decision-makers. This immediate feedback expedites corrective actions and contributes to an ongoing cycle of improvement.

Step 2: Documentation Review

The journey begins with a meticulous review of documentation. Thoroughly examine supplier certificates, material specifications, and compliance records. This step ensures the incoming materials align with your standards and regulatory requirements.

Step 3: Establishing Inspection Criteria

Define clear and precise inspection criteria tailored to your product specifications. This involves collaborating with key stakeholders to establish parameters encapsulating the desired quality benchmarks. Clarity at this stage is paramount for a seamless inspection process.

Step 4: On-Site Inspection: Sampling Techniques

Mastering the art of sampling techniques is pivotal. Employ statistically significant sampling methods to garner insights into the overall quality of the raw materials. This strategic approach minimizes the margin of error, providing a holistic understanding of the material’s characteristics.

Step 5: On-Site Inspection: Utilizing Advanced Testing Methods

Embrace the power of advanced testing methods to delve deeper into the material’s composition.

Techniques such as spectroscopy, chromatography, and microscopy offer unparalleled insights, enabling you to identify subtle anomalies that may elude conventional testing.

Step 6: On-Site Inspection: Real-Time Monitoring

Incorporate real-time monitoring mechanisms during the inspection process. Leveraging technology to track and analyze critical parameters in real-time ensures immediate detection of deviations, allowing for swift corrective actions.

Step 7: Collaboration for Continuous Improvement: Supplier Feedback Loop

A robust supplier feedback loop is a cornerstone of effective raw material inspection. Foster open communication channels with suppliers, providing constructive feedback based on inspection outcomes. This collaborative approach not only rectifies immediate issues but also catalyzes continuous improvement in the supply chain.

Step 8: Continuous Training and Development

Invest in the continuous training and development of your inspection team. Equipping your team with the latest knowledge of materials, testing methodologies, and industry trends enhances their capability to conduct comprehensive inspections.

Step 9: Implementing a Robust Reporting System

Crafting comprehensive inspection reports is an art in itself. Document all findings, deviations, and corrective actions taken. These reports serve as invaluable references for future inspections, contributing to a repository of knowledge that fortifies your quality assurance processes.

Step 10: Data-Driven Decision Making

Harness the power of data-driven decision-making. Analyze inspection data to identify trends, improvement areas, and optimization opportunities. This proactive approach transforms raw material inspection from a routine task into a strategic pillar of your quality management system.

Final Words: Elevating Your Production Excellence

Mastering the steps to conduct raw material inspection is a journey toward production excellence. From meticulous documentation reviews to real-time monitoring and collaborative improvement initiatives, each step plays a pivotal role in shaping the quality landscape of your final product. By embracing these best practices, you meet industry standards and set new benchmarks for excellence.

Incorporating FAT FINGER into your raw material inspection and testing endeavors is a decisive step toward embracing the future. The combination of no-code configuration, real-time collaboration, and data-driven insights

positions your inspection processes at the forefront of efficiency and excellence. Elevate your material inspection to new heights with FAT FINGER, and witness the transformative power of cutting-edge digital solutions.