Chemical Handling Safety is of paramount importance in the Oil and Gas Industry due to the hazardous nature of the substances involved.

In this guide, we will discuss various safety measures that should be taken while handling chemicals in the industry.

Understanding the Importance of Chemical Handling Safety

Minimizing Risks for Personnel

In the Oil and Gas Industry, where operations are intricate and demanding, prioritizing the safety of personnel is non-negotiable.

Chemical handling safety protocols play a pivotal role in minimizing the inherent risks associated with the industry.From drilling to refining, every step involves the use of chemicals, making adherence to safety procedures crucial.

Preventing Environmental Contamination

Beyond the human factor, chemical handling safety is instrumental in preventing environmental contamination. Oil and gas facilities are located in diverse ecosystems, and a spill or mishandling of chemicals can have far-reaching consequences. Our commitment to environmentally responsible practices is reflected in our rigorous adherence to safety protocols, mitigating the environmental impact of our operations.

Best Practices in Chemical Handling Safety

Comprehensive Employee Training

A cornerstone of commitment to safety is comprehensive employee training. Knowledge is power, and when it comes to handling chemicals, there’s no room for error. Every personnel must undergo extensive training programs, equipping them with the knowledge to identify, handle, and mitigate risks associated with various chemicals.

Advanced Technological Solutions

Embracing technological advancements is integral to ensuring chemical handling safety operations. From state-of-the-art monitoring systems to automated handling processes, we can leverage cutting-edge technology to enhance safety measures. This not only minimizes human error but also allows for real-time monitoring and immediate response in case of an unforeseen event.

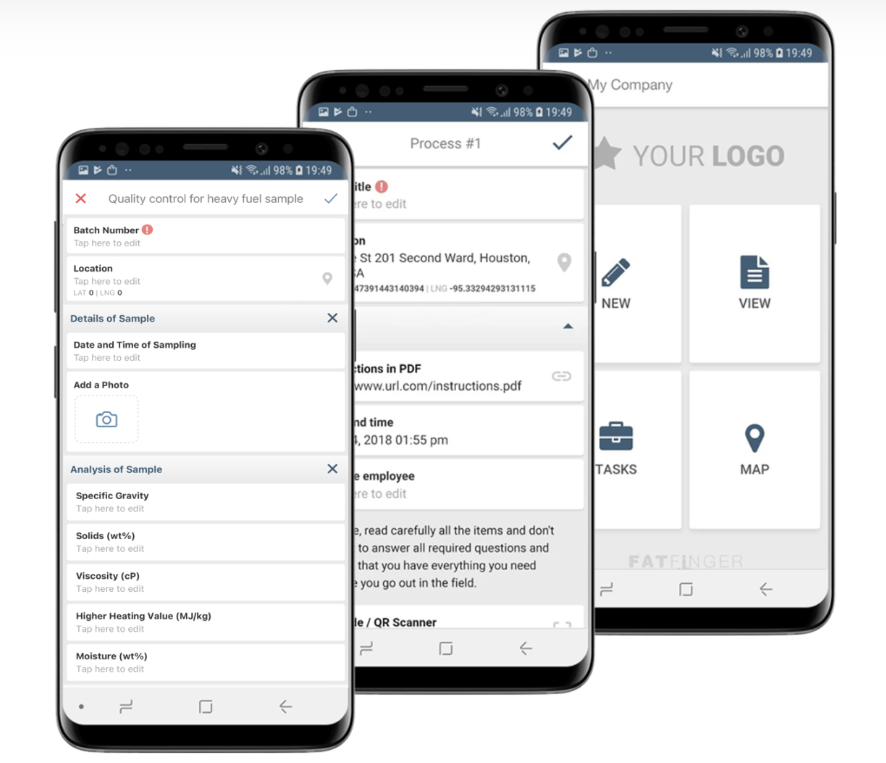

FAT FINGER is a prime example of how technology has revolutionized chemical handling safety. FAT FINGER workflow management software eliminates the risk of human error by automating manual tasks and standardizing procedures. In terms of chemical handling safety, FAT FINGER ensures that the correct procedures are followed at all times, reducing the chances of accidents and promoting a safer work environment.

Personal Protective Equipment (PPE)

Another crucial aspect of chemical handling safety is the use of proper Personal Protective Equipment (PPE). This includes clothing, gloves, masks, and eyewear designed to protect employees from exposure to hazardous chemicals. PPE must be worn at all times when handling chemicals and should be regularly inspected and replaced if damaged.

FAT FINGER as Chemical Handling Safety Partner

At FAT FINGER, we understand the complex and high-risk nature of the Oil and Gas Industry. That’s why we have developed a comprehensive workflow management software specifically designed to enhance chemical handling safety in this industry. Our platform is customizable, easy-to-use, and offers real-time monitoring capabilities to ensure maximum safety at all times.

- Automated Workflows: The FAT FINGER platform automates complex chemical handling processes, ensuring consistency and accuracy. It eliminates the risk of human error, enhancing the safety and efficiency of operations.

- Real-Time Monitoring: With FAT FINGER, you can monitor chemical handling processes in real-time. This feature allows for immediate response to any irregularities or potential risks, further enhancing safety measures.

- Compliance Tracking: FAT FINGER helps maintain compliance with safety protocols and industry standards. The system automatically records every action, providing a comprehensive audit trail that can be used for compliance verification and performance analysis.

4. Customizable and User-Friendly Interface: The FAT FINGER platform is designed with users in mind. Its interface is intuitive and easy-to-use, reducing the time and effort required for training. Plus, it can be customized to fit the specific needs of your operation, ensuring seamless integration into your existing workflows.

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io