Workflow analysis is a critical aspect of production management. It involves the systematic review of work processes to identify inefficiencies and develop strategies for improvement. One tool that has revolutionized Workflow analysis in production is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding Workflow Analysis

Workflow analysis is a method used to understand the sequence of tasks and processes involved in the production of goods or services. It helps identify bottlenecks, redundancies, and inefficiencies that can hinder productivity and quality.

Techniques for Workflow Analysis

There are several techniques used in Workflow analysis. These include:

- Process mapping: This involves creating a visual representation of the workflow to understand the sequence of tasks and identify areas of improvement.

- Time and Motion Studies: This technique involves observing and recording the time taken to perform each task in the workflow. It helps identify inefficiencies and develop strategies to reduce time wastage.

- Value Stream Mapping: This technique focuses on identifying value-adding and non-value-adding activities in the workflow. It helps eliminate waste and improve efficiency.

Role of Tools in Workflow Analysis

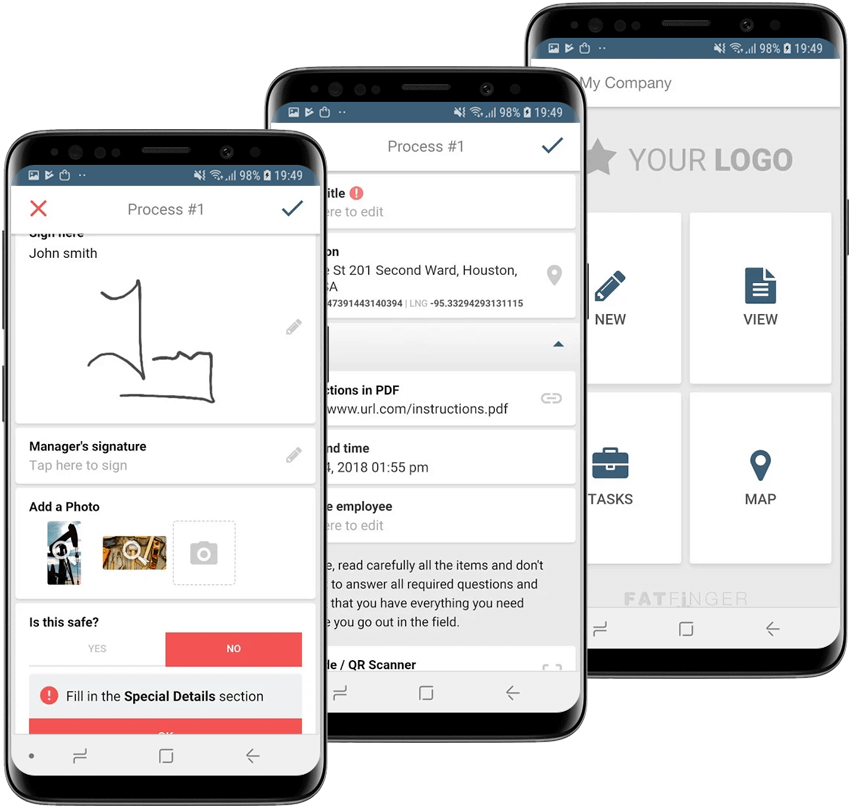

Tools play a crucial role in Workflow analysis. They help automate the process, making it more efficient and accurate. One such tool is FAT FINGER, which allows you to build checklists, workflows, and digital procedures that unlock operational excellence.

How FAT FINGER Enhances Workflow Analysis

FAT FINGER offers a range of features that enhance Workflow analysis in production. These include:

- Drag & Drop Workflow Builder: This feature allows you to easily create and modify workflows, making the process of Workflow analysis more efficient.

- Mobile & Desktop Workflows: FAT FINGER allows you to access and manage workflows from both mobile and desktop devices, enhancing flexibility and convenience.

- Artificial Intelligence Coaching: This feature provides real-time guidance and support, helping teams to perform their tasks correctly every time.

Applications of FAT FINGER in Safety, Maintenance, and Operations

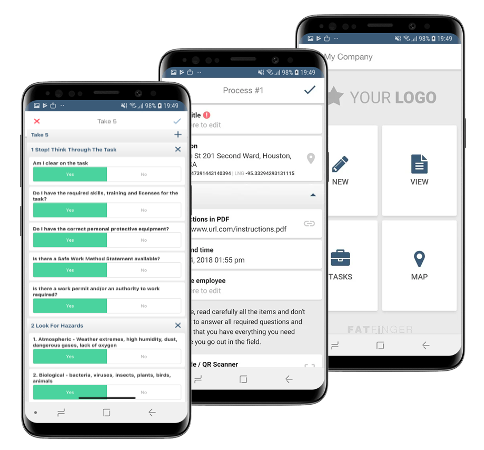

FAT FINGER can be used to create digital workflows and checklists across various safety, maintenance, and operations areas. These include:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

Conclusion

Workflow analysis is a critical aspect of production management. It helps identify inefficiencies and develop strategies for improvement. Tools like FAT FINGER play a crucial role in this process, offering features that enhance efficiency and accuracy. Whether it’s safety, maintenance, or operations, FAT FINGER can help you create digital workflows and checklists that unlock operational excellence.

Ready to take your Workflow analysis to the next level?

Discover the best techniques and tools for improving your production workflow analysis. Learn how to streamline your processes, increase efficiency, and boost productivity. Don’t wait, start your journey to improvement now.