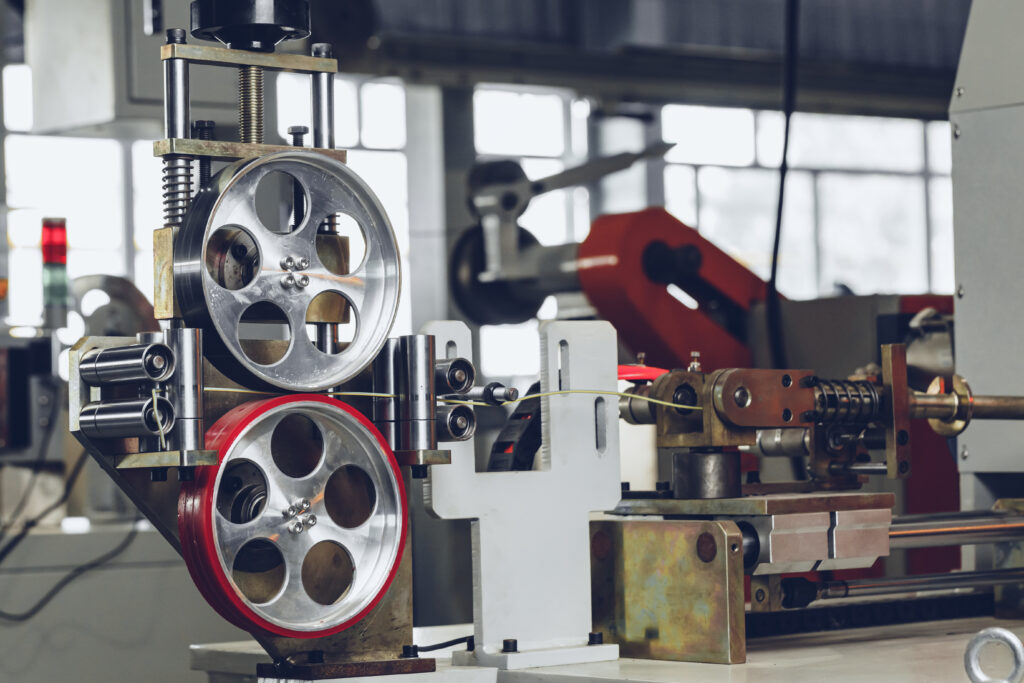

Production planning is a critical process in industrial manufacturing that ensures the efficient use of resources, timely production, and high-quality output. It involves forecasting, scheduling, and controlling the production process to meet customer demands. This guide will delve into the intricacies of Production planning and how digital workflow procedure builders like FAT FINGER can revolutionize this process.

Understanding Production Planning

Production planning is a strategic process that involves determining what products to produce, when to produce them, and how to produce them. It is a crucial aspect of manufacturing that ensures the optimal use of resources and timely delivery of products.

Key Elements of Production Planning

Effective Production planning involves several key elements:

- Forecasting: This involves predicting future demand for products to ensure adequate production.

- Scheduling: This involves determining the sequence of operations and allocating resources accordingly.

- Inventory Management: This involves managing raw materials, work-in-progress, and finished goods to ensure a smooth production process.

- Quality Control: This involves ensuring that the products meet the required standards and specifications.

The Role of FAT FINGER in Production Planning

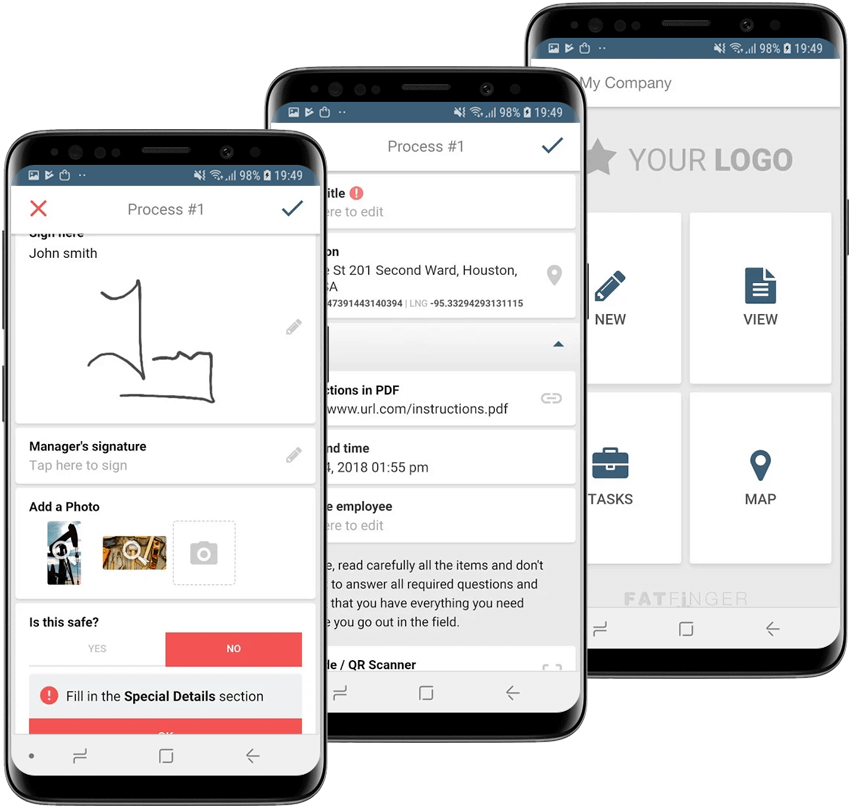

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. FAT FINGER features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, and artificial intelligence coaching.

With FAT FINGER, you can create digital workflows and checklists across safety, maintenance, and operations areas. These solutions include safety take 5, near miss reporting, risk assessment, incident reporting, journey report, material inspection, quality control, shift handover, facility inspection, line changeover, field ticket, work order checklist, truck inspection checks, mobile asset inspection, shutdown/turnaround form, preventive maintenance inspection, and predictive maintenance.

Benefits of Using FAT FINGER in Production Planning

Implementing FAT FINGER in your Production planning process can yield numerous benefits:

- Improved Efficiency: FAT FINGER’s digital workflows and checklists streamline the production process, reducing errors and improving efficiency.

- Enhanced Quality Control: With FAT FINGER, you can easily monitor and control the quality of your products, ensuring they meet the required standards.

- Reduced Costs: By optimizing resource allocation and reducing waste, FAT FINGER can significantly reduce production costs.

- Increased Productivity: FAT FINGER’s intuitive interface and powerful features enable your team to work more productively and effectively.

Case Study: FAT FINGER in Action

A leading industrial manufacturing company implemented FAT FINGER to streamline its Production planning process. The company was able to reduce errors, improve efficiency, and enhance quality control. As a result, the company saw a significant reduction in production costs and an increase in productivity.

Conclusion

Production planning is a critical process in industrial manufacturing that ensures the efficient use of resources, timely production, and high-quality output. Implementing a digital workflow procedure builder like FAT FINGER can revolutionize this process, improving efficiency, enhancing quality control, reducing costs, and increasing productivity.

Don’t miss out on the opportunity to unlock operational excellence in your manufacturing process. Sign up for FAT FINGER or request a demo today!