Product safety is a critical aspect of any manufacturing process. Ensuring that products are safe for use not only protects consumers but also safeguards the reputation of the manufacturer. One of the most effective ways to ensure product safety is through UL (Underwriters Laboratories) factory inspections. In this context, FAT FINGER, a digital workflow procedure builder, plays a pivotal role.

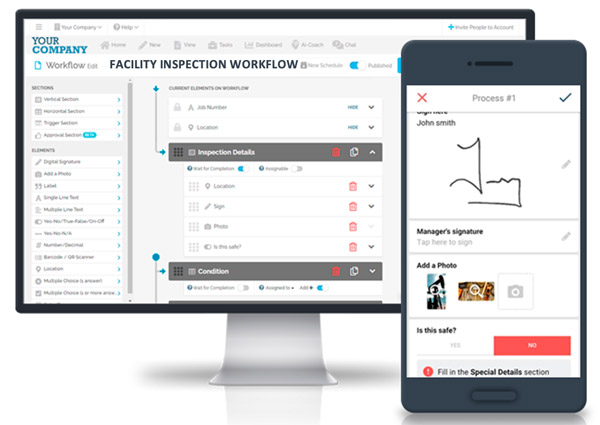

FAT FINGER empowers frontline teams to perform their work correctly every time, by allowing you to build checklists, workflows, and digital procedures that unlock operational excellence. This article will delve into the importance of UL factory inspections for product safety and how FAT FINGER can revolutionize your facility inspections.

Schedule a demo today to see how FAT FINGER can elevate your team’s facility inspection to new heights.

The Importance of UL Factory Inspections

UL factory inspections are a crucial part of the manufacturing process. They ensure that products meet specific safety standards and are safe for consumer use. These inspections are conducted by UL, a global safety certification company that has been in operation for over a century.

Ensuring Compliance with Safety Standards

UL factory inspections ensure that products comply with established safety standards. These standards are designed to protect consumers from potential hazards associated with the use of the product. Non-compliance can lead to product recalls, legal action, and damage to the manufacturer’s reputation.

Preventing Product Recalls

Product recalls can be costly and damaging to a company’s reputation. UL factory inspections help to prevent product recalls by identifying potential safety issues before the product reaches the market.

Building Consumer Trust

UL factory inspections also help to build consumer trust. When consumers see the UL mark on a product, they can be confident that the product has undergone rigorous safety testing and meets established safety standards.

How FAT FINGER Can Revolutionize Your Facility Inspections

FAT FINGER is a digital workflow procedure builder that can revolutionize your facility inspections. With FAT FINGER, you can streamline your checklists, SOPs, and inspections with our intuitive workflow solution. You can also generate professional reports in an instant, ensuring that your facility remains compliant with safety standards.

Key Features of FAT FINGER

- Drag & Drop Workflow Builder: This feature allows you to easily create and modify workflows to suit your specific needs.

- Mobile & Desktop Workflows: FAT FINGER allows you to access your workflows from any device, ensuring that you can conduct inspections and monitor compliance from anywhere.

- Integrations: FAT FINGER can be integrated with other systems, allowing for seamless data transfer and improved efficiency.

- Augmented Reality: This feature allows you to visualize your workflows in a new and engaging way.

- Connect IoT Devices: FAT FINGER allows you to connect IoT devices, providing real-time data and insights.

- Artificial Intelligence Coaching: This feature provides guidance and support, helping you to optimize your workflows and improve efficiency.

Conclusion

UL factory inspections are a critical aspect of product safety. They ensure compliance with safety standards, prevent product recalls, and build consumer trust. FAT FINGER can revolutionize your facility inspections, providing a range of features that allow you to streamline your workflows, conduct inspections from any device, and generate professional reports in an instant.

Build your facility inspection workflow for free with FAT FINGER or schedule a demo today to see how FAT FINGER can elevate your team’s facility inspection to new heights.

Ensure the safety and quality of your products with UL Factory Inspections. Don’t compromise when it comes to consumer safety. Schedule a demo today to understand the importance of UL Factory Inspections for Product Safety.