Energy maintenance and safety standards are critical components of any industrial operation. They ensure the smooth running of operations, protect workers, and safeguard the environment. One tool that is revolutionizing the way these standards are implemented is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. This article explores the role of policy in shaping these standards and how tools like FAT FINGER can help.

Understanding Energy Maintenance and Safety Standards

Energy maintenance and safety standards are guidelines and regulations that govern the operation, maintenance, and safety procedures in the energy sector. They cover a wide range of areas, including:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

The Role of Policy in Shaping These Standards

Policy plays a crucial role in shaping energy maintenance and safety standards. It sets the framework within which these standards are developed, implemented, and enforced. Here are some ways in which policy influences these standards:

- Setting the Agenda: Policy determines the priority areas for energy maintenance and safety. It identifies the key issues that need to be addressed and sets the direction for standard development.

- Regulation: Policy provides the legal framework for the enforcement of energy maintenance and safety standards. It sets the penalties for non-compliance and establishes the mechanisms for monitoring and enforcement.

- Resource Allocation: Policy determines the resources that are allocated to energy maintenance and safety. This includes funding for research and development, training, and enforcement.

Case Study: The Impact of Policy on Energy Maintenance and Safety Standards

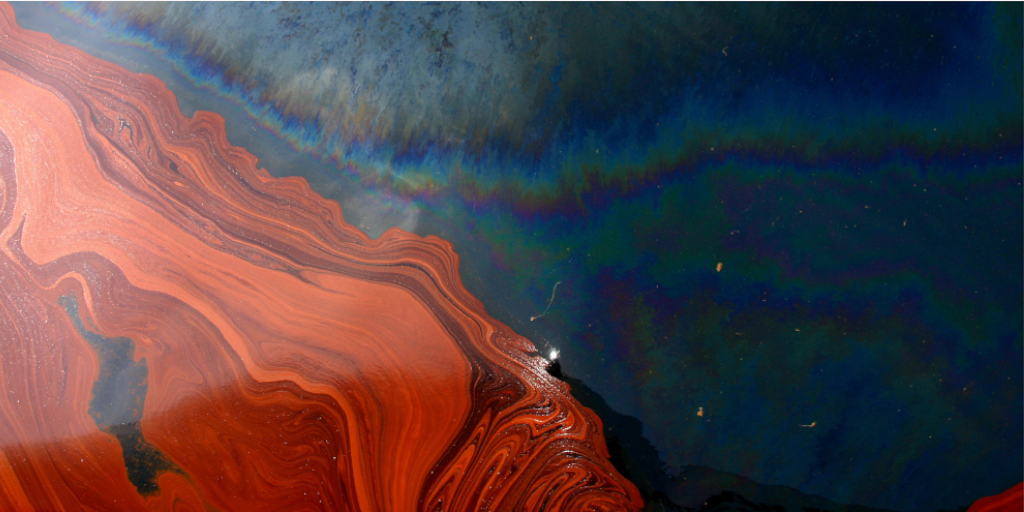

A clear example of the impact of policy on energy maintenance and safety standards can be seen in the aftermath of the Deepwater Horizon oil spill in 2010. In response to the disaster, the U.S. government implemented a series of policy changes aimed at improving safety standards in offshore drilling operations. These included stricter regulations, increased penalties for non-compliance, and enhanced monitoring and enforcement mechanisms. As a result, safety standards in the industry have significantly improved, reducing the risk of similar disasters in the future.

How FAT FINGER Can Help

FAT FINGER is a digital workflow procedure builder that can help organizations implement and adhere to energy maintenance and safety standards. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. Some of its features include:

- Drag & Drop Workflow Builder

- Mobile & Desktop Workflows

- Dashboards

- Integrations

- Augmented Reality

- Connect IoT Devices

- Artificial Intelligence Coaching

By using FAT FINGER, organizations can ensure that their operations are in line with the latest policies and standards, thereby enhancing safety, improving efficiency, and reducing the risk of non-compliance.

Conclusion

Policy plays a crucial role in shaping energy maintenance and safety standards. It sets the agenda, provides the legal framework for enforcement, and determines resource allocation. Tools like FAT FINGER can help organizations adhere to these standards, enhancing safety, improving efficiency, and reducing the risk of non-compliance.

To learn more about how FAT FINGER can help your organization, sign up or request a demo today.