As industries continue to evolve in the digital age, the importance of connected work platforms cannot be overstated. These platforms, such as FAT FINGER, are revolutionizing the way businesses operate, particularly during shutdowns. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence.

Enhanced Safety Measures

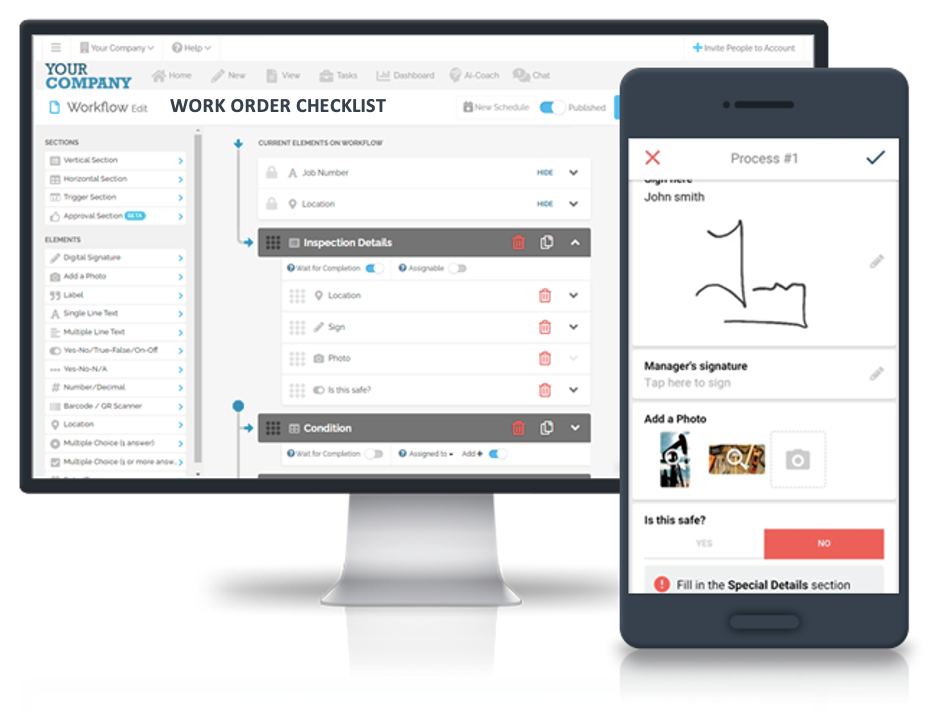

Connected work platforms like FAT FINGER have significantly improved safety measures during shutdowns. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, these platforms provide comprehensive safety solutions.

- Take 5 Safety: This feature allows teams to take a moment to assess the safety of their environment before starting work.

- Near miss reporting: This feature enables teams to report near misses, helping to prevent future incidents.

- JSA / JHA: Job Safety Analysis and Job Hazard Analysis tools help identify potential hazards before they become incidents.

- Risk Assessment: This feature allows teams to assess and manage risks effectively.

- Incident reporting: This feature enables quick and efficient reporting of any incidents that occur.

- Journey report: This feature provides a comprehensive report of the journey, including any incidents or near misses.

Improved Operational Efficiency

Connected work platforms also enhance operational efficiency during shutdowns. FAT FINGER, for instance, offers solutions for operations, maintenance, and safety, ensuring that all aspects of a shutdown are managed effectively.

- Material Inspection: This feature ensures that all materials are inspected and meet the required standards.

- Quality Control: This feature ensures that all operations meet the required quality standards.

- Shift Handover: This feature ensures a smooth transition between shifts, reducing the risk of errors or incidents.

- Facility inspection / Production rounds: This feature allows for regular inspections of the facility, ensuring that it remains safe and operational.

- Line Changeover: This feature ensures a smooth transition when changing production lines.

- Field ticket: This feature allows for efficient tracking and management of field operations.

Proactive Maintenance

Connected work platforms also enable proactive maintenance, which can significantly reduce the risk of incidents during shutdowns. FAT FINGER offers a range of maintenance solutions, including:

- Work Order Checklist: This feature ensures that all work orders are completed correctly and efficiently.

- Truck inspection checks: This feature ensures that all trucks are inspected and safe to use.

- Mobile Asset Inspection: This feature allows for efficient inspection of mobile assets.

- Shutdown / Turnaround form: This feature ensures that all aspects of a shutdown or turnaround are managed effectively.

- Preventive maintenance inspection: This feature allows for regular inspections to prevent potential issues.

- Predictive Maintenance: This feature uses data to predict potential issues before they occur.

Conclusion

In conclusion, connected work platforms like FAT FINGER have a significant impact on safety during shutdowns. They enhance safety measures, improve operational efficiency, and enable proactive maintenance, reducing the risk of incidents and ensuring that shutdowns are managed effectively.

If you’re looking to improve safety and efficiency during shutdowns, consider signing up for FAT FINGER or requesting a demo today.