As we step into the future of manufacturing, the concept of smart factories is becoming increasingly prevalent. These technologically advanced facilities are revolutionizing the way we approach production, and one of the key aspects of this transformation is the evolution of line changeovers. With the help of innovative software solutions like FAT FINGER, the future of line changeovers in smart factories is set to be more efficient, reliable, and seamless than ever before.

About FAT FINGER

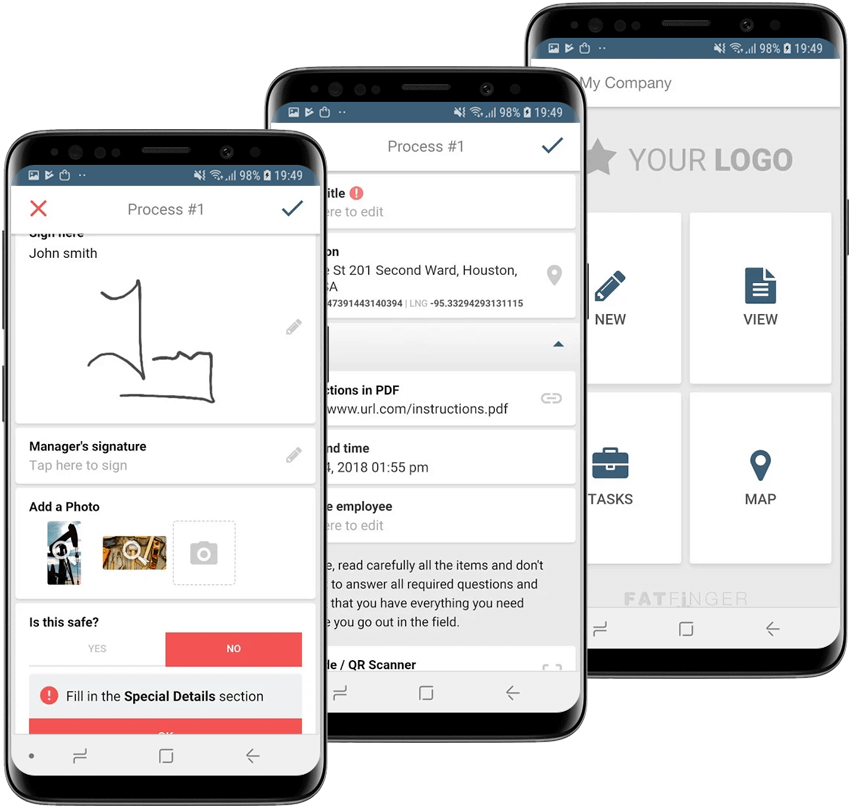

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is a game-changer for line clearance processes. Production Managers have praised FAT FINGER, stating, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.” Request a demo today to see how FAT FINGER can revolutionize your Line Changeover process.

The Future of Line Changeovers in Smart Factories

Line changeover, or line clearance, is the process of verifying that all line changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality. But how is this process evolving in the context of smart factories?

Automation and Digitalization

One of the key trends shaping the future of line changeovers is the shift towards automation and digitalization. With software like FAT FINGER, you can build digital line clearance procedures that facilitate seamless line changeovers. This not only reduces the risk of human error but also significantly speeds up the process, leading to increased productivity and efficiency.

Real-Time Data and Analytics

Another major trend is the use of real-time data and analytics. FAT FINGER’s dashboards and integrations allow for real-time monitoring and analysis of line changeover processes. This enables teams to identify bottlenecks, track performance, and make data-driven decisions to optimize the process.

Augmented Reality and IoT

Technologies like augmented reality and IoT are also playing a crucial role in the future of line changeovers. FAT FINGER’s augmented reality feature can guide operators through the line clearance process, while its IoT connectivity allows for remote monitoring and control of equipment. This not only enhances the efficiency of line changeovers but also improves safety and quality.

Conclusion

The future of line changeovers in smart factories is bright, with technologies like automation, digitalization, real-time data analytics, augmented reality, and IoT paving the way for more efficient, reliable, and seamless processes. With innovative software solutions like FAT FINGER, companies can leverage these technologies to revolutionize their line clearance processes, reduce downtime, improve efficiency, and increase product quality. Sign up for FAT FINGER today to unlock the full potential of your line changeovers and take a step towards the future of smart manufacturing.

Discover the future of line changeovers in smart factories today! Learn how technology is revolutionizing the manufacturing industry and how you can stay ahead of the curve. Visit here to find out more.