In the fast-paced world of manufacturing, efficiency is key. One of the most critical aspects of this efficiency is the ability to quickly and effectively changeover production lines. This is where the importance of equipment design comes into play. With the right equipment design, line changeovers can be facilitated quickly, reducing downtime and increasing productivity.

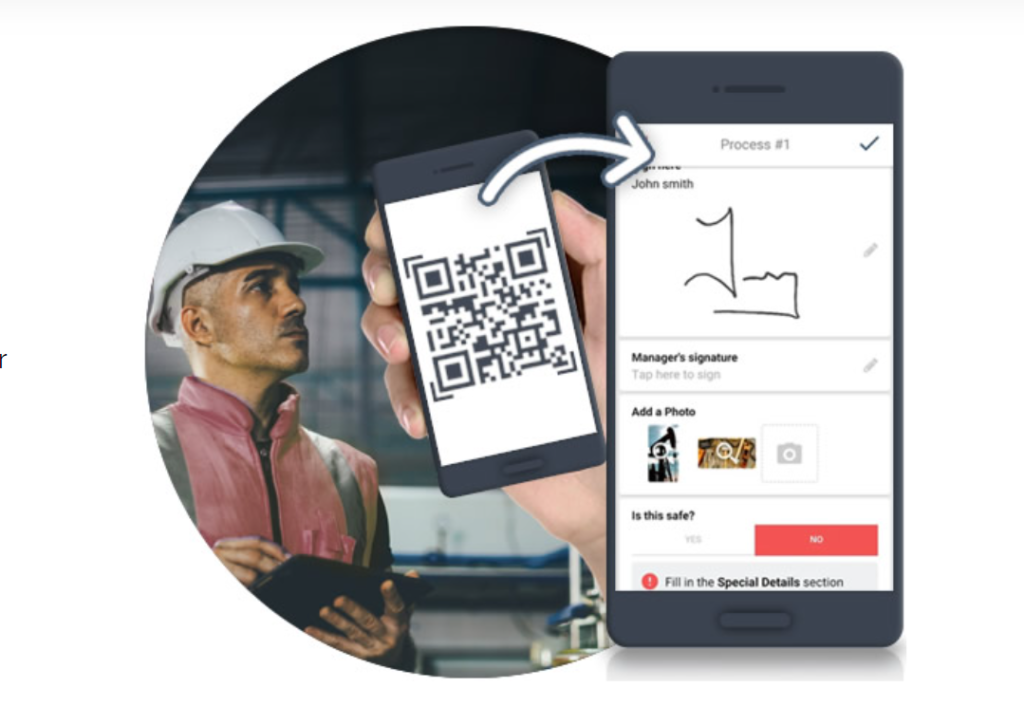

A perfect example of a tool that aids in this process is FAT FINGER. This digital workflow procedure builder empowers front-line teams to do their work correctly every time, by letting you build checklists, workflows, and digital procedures that unlock operational excellence. FAT FINGER is a game changer for production line clearance processes, streamlining production lines with confidence. Request a demo today to see how FAT FINGER can revolutionize your Line Changeover process.

The Importance of Equipment Design in Line Changeovers

Equipment design plays a crucial role in facilitating quick line changeovers. The design of the equipment can either speed up or slow down the changeover process, directly impacting the efficiency and productivity of the production line. Here’s why:

- Reduced Downtime: A well-designed equipment can significantly reduce the time taken for line changeovers, minimizing production downtime.

- Improved Efficiency: Efficient equipment design can streamline the changeover process, enabling the production line to resume operations quickly.

- Increased Product Quality: With a quick and efficient line changeover, the risk of cross-contamination between different products is minimized, leading to improved product quality.

How FAT FINGER Facilitates Quick Line Changeovers

FAT FINGER is a digital workflow procedure builder that is designed to facilitate quick and efficient line changeovers. Here’s how:

- Drag & Drop Workflow Builder: FAT FINGER allows you to easily create and modify workflows for line changeovers, ensuring that all necessary steps are followed.

- Mobile & Desktop Workflows: With FAT FINGER, you can access your workflows from any device, allowing for seamless coordination and communication during the changeover process.

- Integrations: FAT FINGER can be integrated with other systems, providing a comprehensive solution for line changeovers.

- Augmented Reality: FAT FINGER’s augmented reality feature can guide operators through the changeover process, reducing errors and improving efficiency.

- Connect IoT Devices: FAT FINGER can connect with IoT devices, providing real-time data and insights to facilitate quick line changeovers.

- Artificial Intelligence Coaching: FAT FINGER’s AI coaching can provide guidance and support during the changeover process, ensuring that all steps are followed correctly.

Conclusion

In conclusion, the design of equipment plays a crucial role in facilitating quick line changeovers. With the right tools, such as FAT FINGER, line changeovers can be streamlined, reducing downtime, improving efficiency, and increasing product quality. As one Production Manager said, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.” Don’t miss out on the opportunity to revolutionize your line changeover process. Sign up for FAT FINGER today!

Discover the importance of equipment design in facilitating quick line changeovers. Effective design can significantly reduce downtime and increase productivity. Learn more about this crucial aspect of manufacturing efficiency. Click here to delve deeper into the subject.