Manufacturing excellence is a goal that every industry player strives to achieve. One of the most effective methodologies to attain this is through the implementation of Six Sigma.

This article explores how FAT FINGER, a digital workflow procedure builder, can be used to implement Six Sigma for manufacturing excellence. Request a demo today to see how FAT FINGER can revolutionize your manufacturing processes.

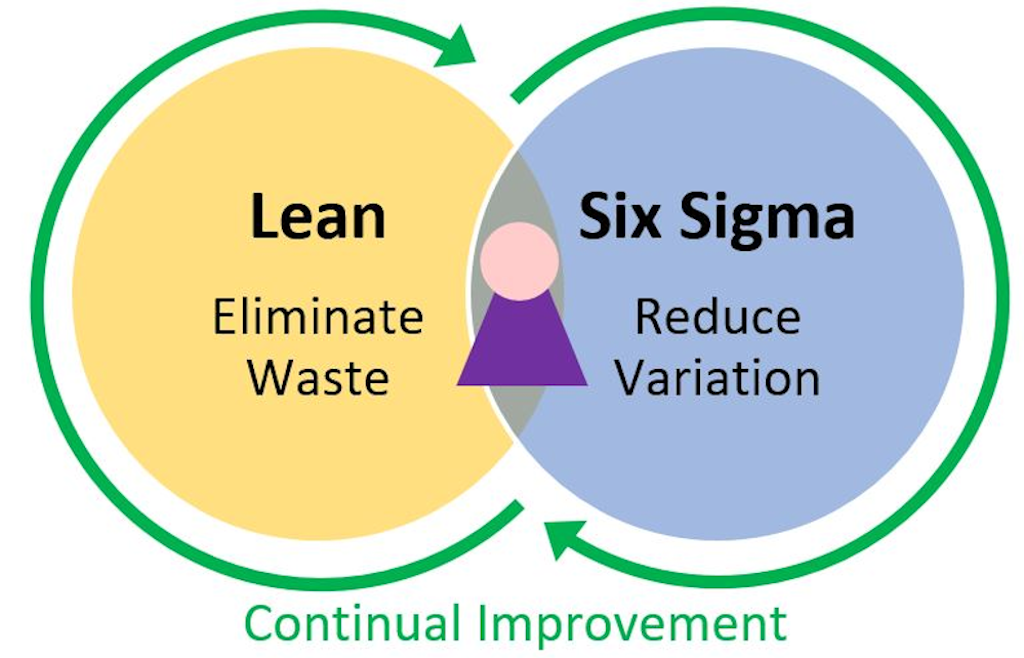

Understanding Six Sigma

Six Sigma is a data-driven approach aimed at eliminating defects and reducing variability in manufacturing and business processes. It uses statistical methods to improve quality and achieve operational excellence. The ultimate goal is to enhance customer satisfaction and bottom-line results.

The Role of FAT FINGER in Implementing Six Sigma

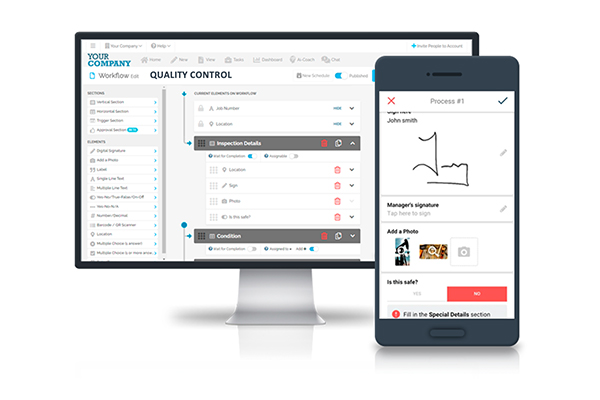

FAT FINGER empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is a game-changer in the manufacturing industry.

Powerful Checklists for Operational Efficiency

With FAT FINGER, you can build powerful checklists to boost operational efficiency. These include:

- Material Inspection: Ensure the highest quality standards of your products with a digital material inspection. Defects can be identified early in the production process before they become too costly.

- Quality Control: Reach maximum production potential with customized automated workflow. Generate custom reports that will keep everyone on track for operational excellence.

- Shift Handover: Modernize your shift transition and watch the savings skyrocket. Automate tedious tasks and keep your entire team in the loop.

- Facility Inspection: Streamline your checklists, SOPs, and inspections with our intuitive workflow solution. Revolutionize facility inspections quickly without compromising excellence.

- Line Changeover: Take your line changeover into a cost-effective future with digitalization. Get your team synced up in no time with automated recurring scheduling.

- Electronic Field Ticket: Upgrade your ticketing system and save big. Boost your team’s productivity with automated field reporting, workforce scheduling, and invoicing.

Case Study: Six Sigma and FAT FINGER in Action

Consider a manufacturing company that implemented Six Sigma using FAT FINGER. They used the platform to create digital workflows for material inspection, Quality Control, shift handover, facility inspection, line changeover, and electronic field ticketing. As a result, they saw a significant reduction in defects, improved quality control, streamlined shift transitions, enhanced facility inspections, seamless line changeovers, and efficient field ticketing. This led to increased productivity, reduced costs, and improved customer satisfaction.

Conclusion

Implementing Six Sigma for manufacturing excellence is a strategic move that can significantly improve your operations. With FAT FINGER, you can easily create digital workflows that align with Six Sigma principles, leading to improved quality, reduced defects, and enhanced operational efficiency. Don’t wait to start your journey towards manufacturing excellence. Build a safety checklist with FAT FINGER today and see the difference it can make in your operations.

Ready to elevate your manufacturing process to new heights of excellence? Implement Six Sigma today and witness a significant improvement in quality and efficiency. Don’t wait, Request A Demo now and start your journey towards manufacturing excellence.