As the oil and gas industry continues to evolve, companies are increasingly turning to innovative technologies to enhance operational visibility and efficiency. One such technology is the Internet of Things (IoT), which, when combined with advanced software solutions like FAT FINGER, can significantly improve the management of shutdowns and turnarounds.

Understanding the Role of IoT Sensors in Oil and Gas Operations

IoT sensors are devices that collect and transmit data from the physical environment. In the oil and gas industry, these sensors can monitor a wide range of parameters, including temperature, pressure, flow rates, and equipment vibration. This real-time data can be used to detect anomalies, predict equipment failures, and optimize operations.

The Power of FAT FINGER in Enhancing Operational Visibility

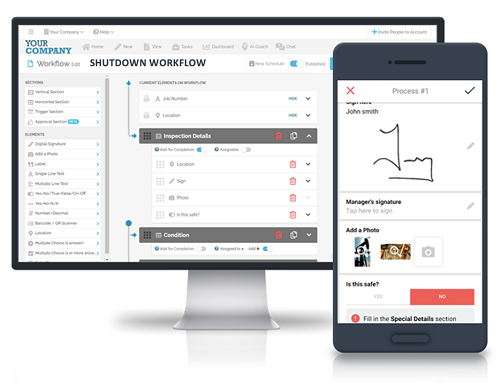

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is a powerful tool for enhancing operational visibility in the oil and gas industry.

How IoT Sensors and FAT FINGER Improve Shutdown Management

Shutdowns and turnarounds in the oil and gas industry are complex, high-stakes operations that require meticulous planning and execution. IoT sensors and FAT FINGER can significantly enhance the management of these operations in several ways:

- Real-time Monitoring: IoT sensors provide real-time data on equipment performance, enabling operators to detect and address issues promptly. This data can be integrated into FAT FINGER’s dashboards, providing a comprehensive view of operations.

- Predictive Maintenance: By analyzing data from IoT sensors, FAT FINGER can predict potential equipment failures and schedule preventive maintenance, reducing downtime and costs.

- Workflow Optimization: FAT FINGER’s workflow builder allows operators to create custom workflows for shutdown operations, ensuring that all tasks are performed correctly and efficiently.

- Improved Safety: IoT sensors can monitor environmental conditions and alert operators to potential safety hazards. FAT FINGER’s safety features, such as near miss reporting and risk assessment, further enhance safety during shutdowns.

Case Study: Enhancing Shutdown Management with IoT and FAT FINGER

A leading oil and gas company used IoT sensors and FAT FINGER to manage a major shutdown. The company installed IoT sensors on its equipment to monitor performance and environmental conditions. This data was integrated into FAT FINGER’s dashboards, providing real-time visibility into operations. The company also used FAT FINGER’s workflow builder to create custom workflows for the shutdown, ensuring that all tasks were performed correctly and efficiently. As a result, the company was able to complete the shutdown on time and under budget, with no safety incidents.

Conclusion

IoT sensors and FAT FINGER offer powerful tools for enhancing operational visibility during oil and gas shutdowns. By providing real-time data, predictive maintenance capabilities, workflow optimization, and improved safety, these technologies can significantly improve the management of shutdowns and turnarounds. As the oil and gas industry continues to evolve, companies that leverage these technologies will be well-positioned to succeed.

Ready to enhance your operational visibility with IoT sensors and FAT FINGER? Sign up today or request a demo to see how FAT FINGER can empower your front-line teams to do their work correctly every time.