Efficiency is the cornerstone of any successful production line. It’s the key to maximizing productivity, reducing costs, and delivering high-quality products on time. In this digital age, tools like FAT FINGER, a digital workflow procedure builder, are revolutionizing the way production lines are set up and managed. This article will explore the best practices and considerations for setting up an efficient production line, with a special focus on how FAT FINGER can empower your front-line teams to do their work correctly every time.

Understanding the Basics of Production Line Efficiency

Before diving into the best practices, it’s crucial to understand what production line efficiency entails. It’s about optimizing the use of resources – time, labor, and materials – to achieve the highest possible output with the least waste. This involves careful planning, regular monitoring, and continuous improvement.

Best Practices for Setting Up an Efficient Production Line

Here are some proven strategies for setting up an efficient production line:

- Process Mapping: This involves creating a visual representation of the production process, identifying each step, the time it takes, and the resources it requires. It helps identify bottlenecks and areas for improvement.

- Lean Manufacturing: This approach focuses on minimizing waste while maximizing productivity. It involves practices like just-in-time production, where materials are only ordered and used as needed, reducing storage costs and waste.

- Automation: Automating repetitive tasks can significantly increase efficiency. This can range from using machinery for physical tasks to using software like FAT FINGER for workflow management.

- Continuous Improvement: Efficiency is not a one-time goal but a continuous process. Regularly review and update your processes to keep up with changes in technology, market demand, and other factors.

Considerations When Setting Up an Efficient Production Line

While implementing the above practices, consider the following:

- Employee Training: Even the most efficient production line won’t be effective if employees don’t know how to use it. Invest in regular training to ensure your team can operate new machinery or software effectively.

- Cost vs. Benefit: While automation and other efficiency measures can save money in the long run, they often require a significant upfront investment. Consider the cost-benefit analysis before implementing any major changes.

- Flexibility: Your production line should be flexible enough to adapt to changes in demand, product design, or production methods. This might involve modular equipment that can be easily reconfigured, or software like FAT FINGER that can be easily updated to reflect new workflows.

How FAT FINGER Can Help

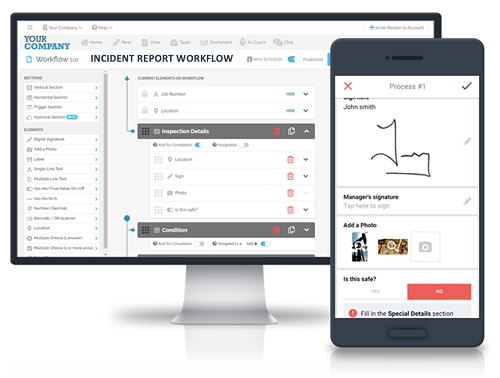

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, and artificial intelligence coaching, FAT FINGER can significantly enhance your production line efficiency.

Whether it’s safety procedures like near miss reporting and risk assessment, operations tasks like quality control and shift handover, or maintenance activities like work order checklists and predictive maintenance, FAT FINGER can help streamline your processes and ensure they’re carried out correctly every time.

Conclusion

Setting up an efficient production line involves careful planning, continuous improvement, and the right tools. By following the best practices and considerations outlined in this article, you can maximize your productivity, reduce waste, and ensure high-quality output. Tools like FAT FINGER can play a crucial role in this process, providing a simple and effective way to manage your workflows and empower your front-line teams.

Ready to take your production line efficiency to the next level? Sign up for FAT FINGER or request a demo today to see how it can transform your operations.

Discover the best practices and considerations for setting up an efficient production line. Learn how to streamline your operations, reduce waste, and increase productivity. Don’t wait, start improving your production line today.