Manufacturing is a complex industry that involves numerous processes, each with its own set of risks. To ensure safety and efficiency, it is crucial to utilize the right Risk Assessment Instruments. One such tool that has revolutionized risk management in manufacturing is FAT FINGER. This digital workflow procedure builder empowers front-line teams to do their work correctly every time, unlocking operational excellence. With FAT FINGER, you can build digital workflow procedures to improve Risk Assessment and manage risks in your facility. Request a demo today to see how FAT FINGER can transform your risk management strategy.

The Importance of Risk Assessment in Manufacturing

Risk assessment is a critical component of any manufacturing process. It involves identifying potential hazards, evaluating their likelihood and severity, and implementing measures to mitigate them. This process is not only essential for ensuring the safety of workers but also for maintaining operational efficiency and preventing costly disruptions.

Choosing the Right Risk Assessment Instruments

Choosing the right Risk Assessment Instruments is crucial for effective risk management. These tools should be able to:

- Identify potential hazards

- Evaluate the likelihood and severity of these hazards

- Provide actionable insights for risk mitigation

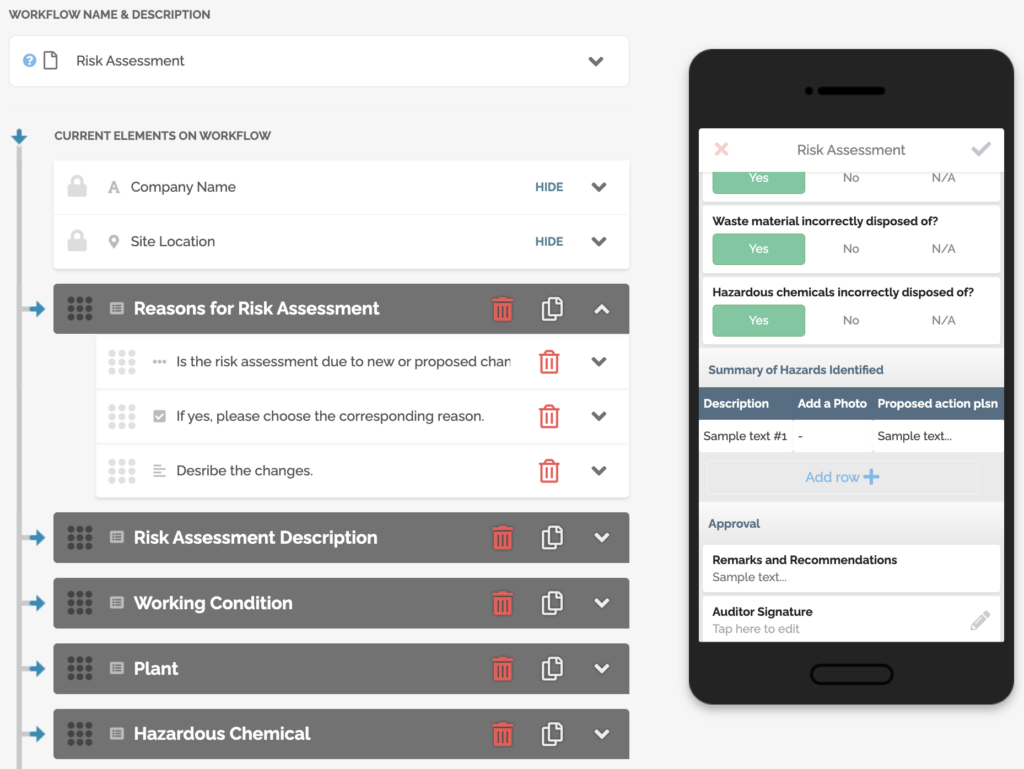

One such tool that meets all these requirements is FAT FINGER. With its intuitive drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER provides a comprehensive solution for risk assessment in manufacturing.

How FAT FINGER Enhances Risk Assessment

FAT FINGER enhances risk assessment in several ways. Firstly, it allows you to build digital workflow procedures that make safety and preventive measures everyone’s responsibility. This not only ensures that all potential hazards are identified but also that they are addressed promptly and effectively.

Secondly, FAT FINGER allows you to create risk assessment checklists that help safeguard your company from threats. These checklists can be customized to suit your specific needs and can be easily shared across all your sites, ensuring consistent safety standards.

Finally, FAT FINGER’s paperless, risk-free digital workflow eliminates the risk of lost or misplaced documents, ensuring that all safety procedures are followed to the letter.

Conclusion

In conclusion, utilizing the right Risk Assessment Instruments is crucial for effective risk management in manufacturing. Tools like FAT FINGER not only help identify and evaluate potential hazards but also provide actionable insights for risk mitigation. By making safety and preventive measures everyone’s responsibility, these tools can significantly enhance the safety and efficiency of your manufacturing processes.

Sign up for a free trial today to see how FAT FINGER can transform your risk management strategy.

Don’t leave your manufacturing process to chance. Utilize the right risk assessment instruments to ensure safety and efficiency. Learn more about how these tools can transform your operations. Request a demo today.