Manufacturing safety is a critical aspect of any industrial operation. It not only ensures the well-being of employees but also contributes to the overall productivity and efficiency of the organization. One innovative approach to enhancing safety in manufacturing is the use of Risk Assessment heat maps. This article will delve into how these heat maps, when integrated with a powerful tool like FAT FINGER, can significantly improve safety in the manufacturing sector.

Request a demo of FAT FINGER today and discover how it can revolutionize your approach to manufacturing safety.

Understanding Risk Assessment Heat Maps

Risk assessment heat maps are visual tools that help identify, assess, and prioritize risks in a manufacturing environment. They use colors to represent different levels of risk, making it easier for teams to understand and address potential hazards. However, the effectiveness of these heat maps can be significantly enhanced when combined with a digital workflow procedure builder like FAT FINGER.

Introducing FAT FINGER

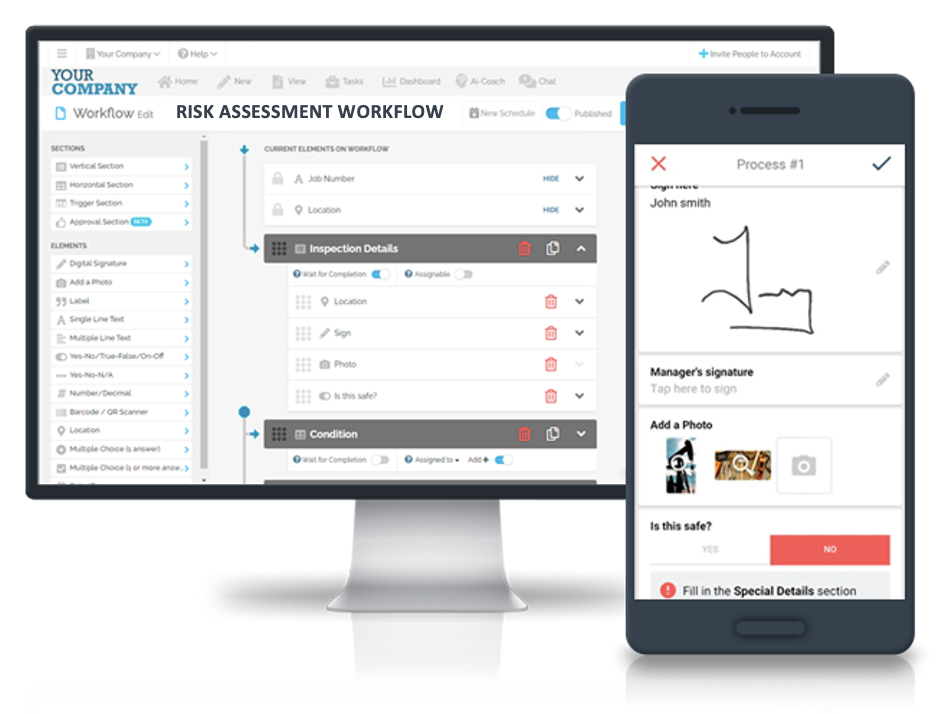

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is a comprehensive solution for managing risks in your facility.

Enhancing Safety with FAT FINGER

With digital procedures built with FAT FINGER, safety and preventive measures become everyone’s responsibility. Risk Assessment Checklists built with FAT FINGER help safeguard your company from threats. This intuitive digital workflow is paperless and risk-free. Every site has its own potential hazards. In FAT FINGER, you can import different safety processes and make them your own, or simply create one from scratch. Once you’re done, you can export your safety workflow to all of your different sites.

Case Study: Improving Safety with FAT FINGER

Consider the case of a large manufacturing company that was struggling with safety issues. They implemented FAT FINGER and used its features to create a comprehensive risk assessment checklist. This checklist was then used to generate a Risk Assessment Heat Map, which visually represented potential hazards in their facility. The result was a significant reduction in safety incidents and an overall improvement in operational efficiency.

Statistics Supporting the Use of FAT FINGER

Companies that have implemented FAT FINGER have reported impressive results. For instance, they have seen a 30% reduction in safety incidents and a 20% increase in operational efficiency. These statistics clearly demonstrate the value of integrating FAT FINGER into your manufacturing safety procedures.

Conclusion

Improving manufacturing safety is a critical task that requires innovative solutions. Risk assessment heat maps, when combined with a powerful tool like FAT FINGER, can significantly enhance safety in the manufacturing sector. By allowing you to create comprehensive checklists and workflows, FAT FINGER makes safety everyone’s responsibility. The result is a safer, more efficient, and more productive manufacturing operation.

Sign up for a free trial of FAT FINGER today and discover how it can revolutionize your approach to manufacturing safety.

Discover how to improve manufacturing safety with our innovative Risk Assessment Heat Maps. These tools provide a visual representation of potential hazards, allowing you to take proactive measures to ensure a safer work environment. Don’t wait, take the first step towards a safer manufacturing process today. Request a demo now.