Raw material inspection is a critical aspect of ensuring product quality and reliability. This comprehensive guide delves into the nuances of this essential process, shedding light on its significance and providing valuable insights.

From the initial steps to the intricacies of inspection techniques, this article aims to equip you with a thorough understanding of raw material inspection.

What is raw material inspection?

Raw material inspection, often overlooked in its importance, is the cornerstone of quality assurance in manufacturing. The process involves scrutinizing raw materials before production, ensuring they meet predefined standards. Regardless of the industry, manufacturers rely on this meticulous examination to guarantee the end product’s integrity.

The heart of raw material inspection lies in a comprehensive examination. Experts meticulously scrutinize materials’ physical, chemical, and even microscopic aspects. This keen attention allows for identifying potential issues that compromise the quality of the final product.

Raw Material Inspection For Quality Control

Raw material inspection is proactive, enabling manufacturers to address challenges before they escalate preemptively. This early identification of potential issues translates into significant cost savings, as rectifying defects during the initial stages of production is far more economical than addressing them later in the process.

Moreover, the efficiency gains from a well-executed inspection process ripple through the entire manufacturing cycle, optimizing resources and timelines.

Armed with insights from raw material inspections, you can fine-tune production processes, resulting in a more streamlined and cost-effective operation. Ultimately, this commitment to rigorous inspection safeguards against defects and elevates the overall efficiency and reputation of the manufacturing enterprise.

In a nutshell, raw material inspection serves as the first line of defense against defects and inconsistencies. By identifying potential issues early in the production chain, manufacturers can prevent costly defects, improve efficiency, and maintain a stellar reputation for delivering top-notch products.

Aligning Quality Inspection Processes with Industry Standards

Compliance with industry standards in raw material inspection is a strategic commitment that reverberates throughout the entire production ecosystem.

LSI Keywords such as “industry standards,” “compliance,” and “quality assurance” underline the significance of aligning inspection processes with established norms. This ensures uniformity, safety, and regulatory compliance.

Manufacturers navigating the intricate web of industry standards find that this commitment lays the groundwork for consistent quality, reducing the likelihood of deviations that could compromise the safety and reliability of the end product.

Common Challenges in Raw Material Inspection

Obstacles such as inconsistent suppliers, variable material quality, and evolving industry regulations are common in raw material inspection.

Supplier Variability

Suppliers may deliver materials with fluctuations in quality, quantity, or adherence to specifications, posing a significant challenge to the uniformity of the production process. You can mitigate against this challenge through clear communication, standardized quality criteria, and periodic supplier evaluations.

Industry regulations

Evolving industry regulations constitute an additional layer of complexity. As regulatory landscapes continuously shift, manufacturers must stay vigilant to ensure compliance. Navigating these ever-changing requirements demands a proactive approach, necessitating constant monitoring, adaptation, and, sometimes, a strategic overhaul of existing inspection processes.

Variability of raw materials

Another pressing challenge is the variable quality of the materials themselves. Subject to natural variations or influenced by external factors, raw materials can introduce unpredictability into the manufacturing equation. Negotiating these fluctuations requires a keen understanding of the material’s inherent characteristics and the implementation of adaptable inspection protocols.

The challenges inherent in raw material inspection demand a multifaceted strategy that includes the following:

- Fostering transparent communication with suppliers

- Implementing flexible inspection protocols

- Staying abreast of regulatory changes

By upholding this strategy, you can navigate common hurdles with resilience and agility to uphold the integrity of their production processes.

Techniques for Effective Raw Material Inspection

Embracing cutting-edge inspection methods is key to staying ahead in inspection. Two key inspection techniques that elevate the quality control process include the following:

- Non-destructive testing

- Spectroscopy

Non-destructive testing stands out as a game-changer, allowing inspectors to scrutinize materials without altering their integrity. This technique is particularly invaluable when dealing with delicate or limited-quantity materials, providing detailed insights without compromising usability.

Spectroscopy delves into the molecular composition of materials, offering a level of analysis beyond surface-level inspection. This enables inspectors to identify subtle variations or contaminants that may elude traditional methods.

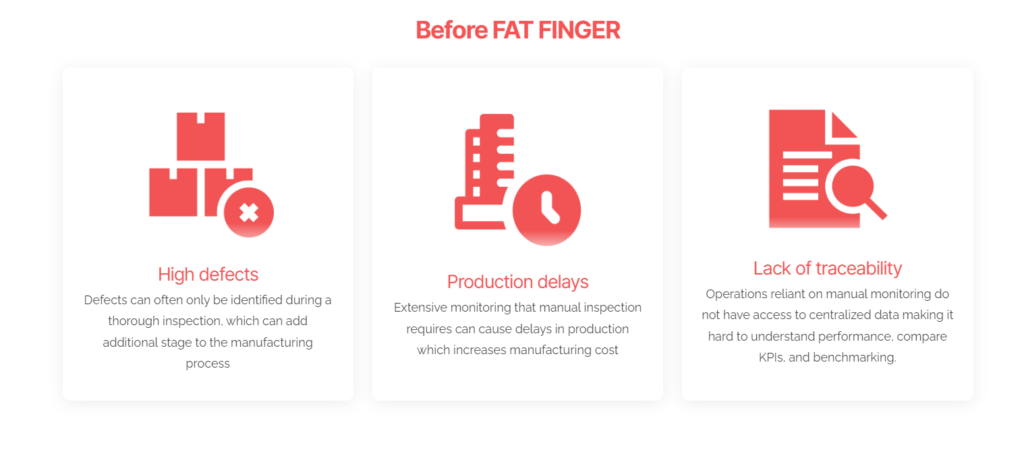

Leveraging FAT FINGER for Enhanced Inspections

FAT FINGER provides a cutting-edge approach that revolutionizes the accuracy and efficiency of the entire process in raw material inspections and testing.

FAT FINGER, a user-friendly and intuitive mobile application, empowers inspectors to streamline their tasks, minimizing the potential for human error

The application provides a digital interface for data collection, enabling inspectors to input information directly into a centralized system. This eliminates the need for manual paperwork and significantly reduces the likelihood of transcription errors, ensuring the integrity of inspection records.

FAT FINGER also facilitates real-time collaboration among inspection teams. Inspectors can instantly share findings, updates, and notes through the application, promoting seamless communication and coordination. This level of connectivity ensures that all team members are well-informed and aligned in their inspection processes. This instantaneous collaboration accelerates decision-making, allowing for swift responses to any issues identified during the inspection.

More so, FAT FINGER allows you to Customize your own digital procedures, meaning you can tailor inspection checklists and parameters to the unique requirements of your industry and materials. Whether configuring inspection criteria for chemical compositions, physical attributes, or adherence to specific standards, the flexibility of FAT FINGER will empower your organization to design a tailored inspection framework that maximizes the effectiveness of your quality control processes.