Quality control inspections are a crucial aspect of manufacturing processes, ensuring that products meet the required standards and specifications. They play a pivotal role in maintaining product quality, reducing errors, and preventing costly recalls. In this digital age, innovative solutions like FAT FINGER are revolutionizing QC Inspections, making them more efficient and reliable.

FAT FINGER is a digital workflow procedure builder that empowers frontline teams to perform their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. This article will delve into the intricacies of QC Inspections and how FAT FINGER can elevate your team’s facility inspection to new heights. Schedule a demo to see how FAT FINGER can revolutionize your QC Inspections.

Understanding QC Inspections

QC Inspections involve a systematic examination of a product or service to assess whether it meets specified criteria. These inspections are typically carried out at various stages of the manufacturing process, including:

- Initial production check

- During production check

- Pre-shipment inspection

- Container loading check

These inspections help identify defects early, allowing for timely corrective actions and preventing substandard products from reaching the market.

The Importance of QC Inspections in Manufacturing

QC Inspections are integral to the manufacturing process for several reasons:

- They ensure that products meet the required quality standards, enhancing customer satisfaction and brand reputation.

- They help identify defects early, reducing the cost of rework and waste.

- They ensure compliance with regulatory standards, avoiding penalties and legal issues.

- They contribute to continuous improvement by providing valuable insights into the manufacturing process.

Revolutionizing QC Inspections with FAT FINGER

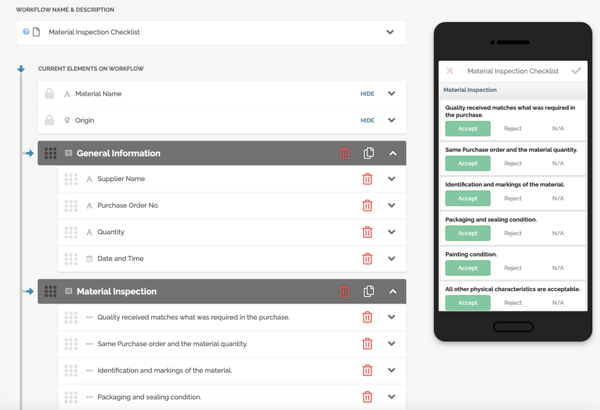

FAT FINGER is a game-changer in the realm of QC Inspections. It allows you to streamline your checklists, SOPs, and inspections with an intuitive workflow solution. You can drag and drop digital procedures onto a platform directly where work is done, generating professional reports in an instant. FAT FINGER features include:

- Drag & Drop Workflow Builder

- Mobile & Desktop Workflows

- Dashboards

- Integrations

- Augmented Reality

- Connect IoT Devices

- Artificial Intelligence Coaching

With FAT FINGER, you can revolutionize facility inspections quickly without compromising excellence.

Case Study: FAT FINGER in Action

Consider the case of a leading manufacturing company that was struggling with manual QC Inspections. The process was time-consuming, error-prone, and lacked real-time visibility. After implementing FAT FINGER, the company was able to automate its QC Inspections, reducing errors and saving time. The team could easily build and customize digital checklists, ensuring that nothing was overlooked. The real-time dashboards provided valuable insights into the inspection process, enabling continuous improvement. This case study underscores the transformative potential of FAT FINGER in QC Inspections.

Conclusion: Ensuring Quality with FAT FINGER

In conclusion, QC Inspections are vital in ensuring quality in manufacturing processes. They help maintain product quality, reduce errors, and prevent costly recalls. Innovative solutions like FAT FINGER are revolutionizing QC Inspections, making them more efficient and reliable. With features like drag and drop workflow builder, mobile and desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and AI coaching, FAT FINGER can elevate your QC Inspections to new heights.

Build your facility inspection workflow for free with FAT FINGER or schedule a demo to see how FAT FINGER can revolutionize your QC Inspections.

Discover how QC Inspections can ensure quality in your manufacturing processes. Learn more about the intricacies and benefits of this crucial procedure. Don’t leave quality to chance, take control of your production today. Schedule a demo now and see how QC Inspections can transform your manufacturing process.