As the manufacturing industry continues to evolve, the integration of collaborative robotics in line changeovers has become a significant trend. This article explores the opportunities and challenges of this integration, with a particular focus on how FAT FINGER, a digital workflow procedure builder, can facilitate seamless line changeovers.

What is Collaborative Robotics?

Collaborative robotics, also known as cobots, are designed to work alongside humans in a shared workspace. Unlike traditional robots, cobots are equipped with advanced sensors and software that allow them to interact safely and efficiently with human workers. They are typically used to automate repetitive tasks, freeing up human workers to focus on more complex and value-added activities.

Opportunities of Collaborative Robotics in Line Changeovers

Integrating cobots into line changeovers can bring numerous benefits:

- Increased Efficiency: Cobots can perform tasks faster and more accurately than humans, reducing the time required for line changeovers.

- Improved Quality: Cobots can perform tasks with a high level of precision, reducing the risk of errors and improving product quality.

- Enhanced Safety: Cobots can handle hazardous materials and perform tasks in dangerous environments, reducing the risk of accidents and injuries.

- Reduced Downtime: With the help of digital workflow builders like FAT FINGER, cobots can ensure that all Line Changeover activities are completed correctly every time, reducing downtime and improving line efficiency.

Challenges of Collaborative Robotics in Line Changeovers

Despite these benefits, there are also challenges to consider:

- High Initial Investment: Cobots can be expensive to purchase and install, which may be a barrier for small and medium-sized enterprises.

- Technical Skills: Workers need to be trained to operate and maintain cobots, which can be time-consuming and costly.

- Integration Issues: Integrating cobots into existing production lines can be complex and may require significant changes to workflows and processes.

How FAT FINGER Can Help

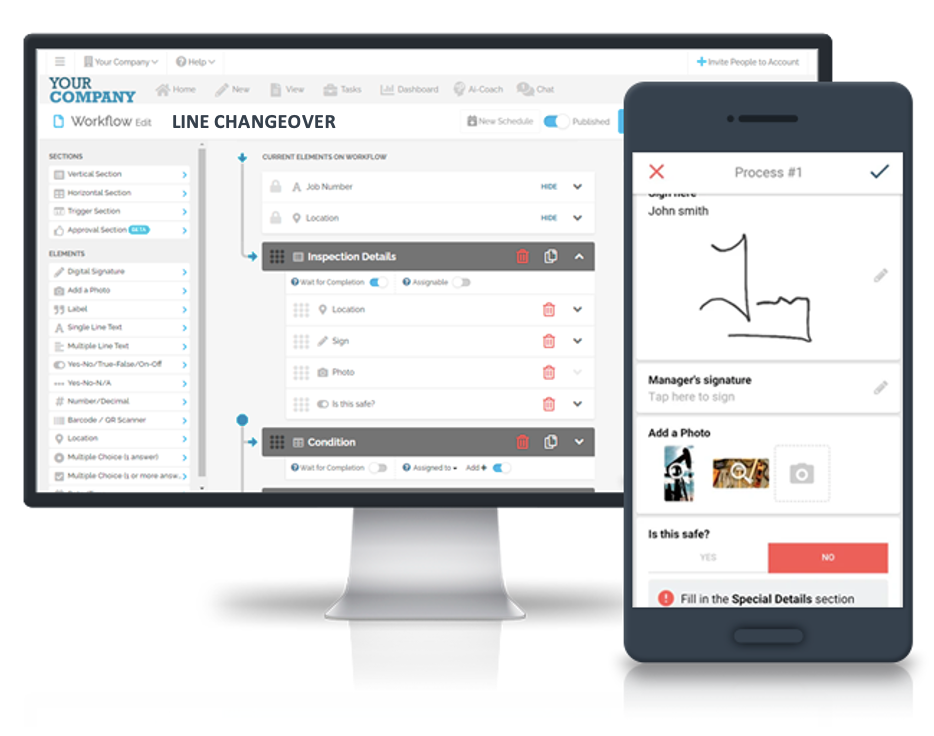

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With its drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER can build digital line clearance procedures to facilitate seamless line changeovers.

Production Managers who have used FAT FINGER have praised its ability to streamline their production line clearance process. As one manager put it, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.”

Conclusion

While the integration of collaborative robotics in line changeovers presents both opportunities and challenges, digital workflow builders like FAT FINGER can play a crucial role in facilitating this integration. By automating repetitive tasks, improving accuracy, and reducing downtime, cobots can significantly enhance the efficiency and quality of line changeovers. However, it’s important to consider the initial investment, the need for technical skills, and potential integration issues. With the right planning and support, cobots can be a valuable addition to any manufacturing line.

Interested in seeing how FAT FINGER can streamline your line changeovers? Request a demo today.

Ready to take your line changeovers to the next level? Sign up to FAT FINGER now.

Discover the opportunities and challenges of Collaborative Robotics in Line Changeovers. Learn how to optimize your production line, reduce downtime, and enhance efficiency. For more information, click here to explore the potential of this innovative technology.