Manufacturing safety is a critical aspect of any industrial operation. It not only ensures the well-being of employees but also contributes to the overall productivity and efficiency of the organization. One of the key components of manufacturing safety is Risk Assessment. This process helps identify potential hazards, evaluate their impact, and develop strategies to mitigate them.

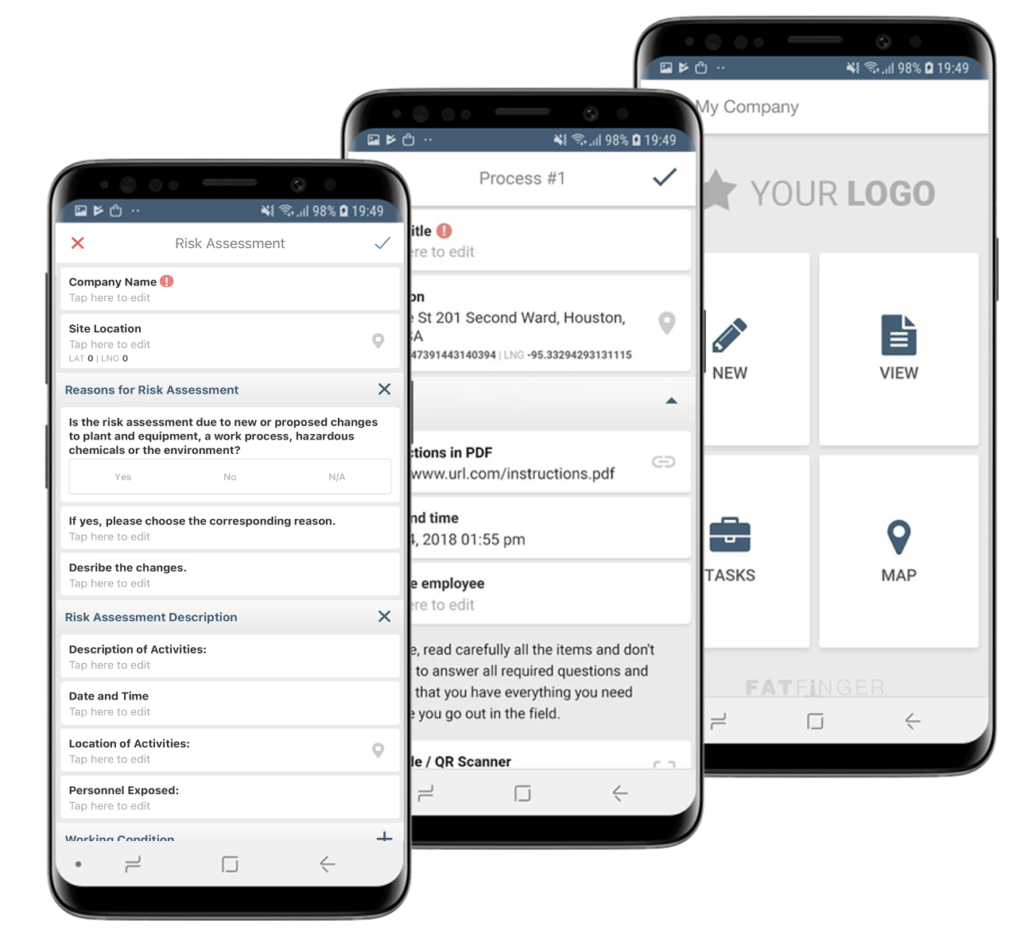

In this context, FAT FINGER, a digital workflow procedure builder, plays a pivotal role. FAT FINGER empowers front-line teams to do their work correctly every time, by letting you build checklists, workflows, and digital procedures that unlock operational excellence. With FAT FINGER, you can improve risk assessment and manage risks in your facility effectively. Request a demo to see how FAT FINGER can revolutionize your risk assessment process.

The Essential Purpose of Risk Assessment in Manufacturing Safety

Risk assessment is a systematic approach to identifying potential hazards in a workplace, evaluating the risk associated with each hazard, and determining appropriate ways to eliminate or control the hazard. It is a proactive measure that aims to prevent accidents before they occur.

Identification of Potential Hazards

The first step in risk assessment is to identify potential hazards. These could range from machinery malfunctions to chemical spills, and from ergonomic issues to fire hazards. FAT FINGER’s intuitive digital workflow allows you to import different safety processes and make them your own, or simply create one from scratch.

Evaluation of Risks

Once potential hazards are identified, the next step is to evaluate the risks associated with each hazard. This involves determining the likelihood of the hazard occurring and the severity of its impact. FAT FINGER’s dashboards and integrations provide a comprehensive view of all potential risks, helping you make informed decisions.

Development of Mitigation Strategies

The final step in risk assessment is to develop strategies to eliminate or control the identified hazards. This could involve implementing safety measures, providing training to employees, or redesigning work processes. FAT FINGER’s drag & drop workflow builder allows you to build digital procedures that ensure safety measures are implemented correctly every time.

Case Study: The Role of FAT FINGER in Risk Assessment

Consider the case of a large manufacturing company that was struggling with frequent workplace accidents. After implementing FAT FINGER, the company was able to identify potential hazards, evaluate their risks, and develop effective mitigation strategies. As a result, the company saw a significant reduction in workplace accidents and an improvement in overall productivity.

Conclusion

Risk assessment is an essential component of manufacturing safety. It helps identify potential hazards, evaluate their risks, and develop strategies to mitigate them. FAT FINGER plays a crucial role in this process by providing a platform to build digital procedures that ensure safety measures are implemented correctly every time. With FAT FINGER, you can make safety and preventive measures everyone’s responsibility.

Sign up for free to see how FAT FINGER can revolutionize your risk assessment process.

Understanding the essential purpose of risk assessment in manufacturing safety is crucial for any business. It helps to identify potential hazards, evaluate risks, and implement measures to reduce these risks. Don’t leave your employees’ safety to chance. Learn more about how risk assessment can protect your business and your team. Request a demo today.