In the dynamic world of the oil and gas industry, asset management is a critical aspect that can significantly impact operational efficiency and profitability. One of the key components of effective asset management is using a mobile asset tag.

This article delves into the concept of mobile asset tagging in the oil and gas industry and how FAT FINGER’s digital workflows, particularly the mobile asset inspection workflow, can revolutionize this process.

What is Mobile Asset Tagging in Oil and Gas?

Mobile Asset Tagging in the Oil and Gas industry refers to the practice of attaching identifiers, or tags, to equipment, machinery, and other physical assets. These tags are often in the form of barcodes, QR codes, or RFID (Radio-Frequency Identification) tags.

The purpose of this practice is to track and monitor the location, status, and condition of the assets in real-time. This information can be accessed and updated via mobile devices, hence the term ‘mobile’ asset tagging.

In the oil and gas industry, mobile asset tagging is particularly important due to the large number of assets, often located in remote or hard-to-reach places.

- The tags can provide data on a wide range of factors including operational status, maintenance needs, and asset lifespan.

- Mobile asset tagging can contribute to increased operational efficiency by reducing the time and resources spent on manually tracking assets.

- It can also enhance safety measures by providing real-time updates on equipment conditions, and assist in regulatory compliance by providing accurate asset records.

- Additionally, with the use of analytics, the data gathered from these tags can aid in predictive maintenance, thereby reducing downtime and potential equipment failure.

In summary, Mobile Asset Tagging in Oil and Gas is a modern approach to asset management that leverages technology to improve efficiency, safety, and compliance in the industry.

The Importance of Mobile Asset Tagging in Oil and Gas

Using a mobile asset tag brings several benefits to the oil and gas industry:

- Enhanced asset tracking and management

- Improved maintenance scheduling

- Reduced downtime

- Increased operational efficiency

- Improved safety and compliance

However, traditional methods of asset tagging can be time-consuming, error-prone, and inefficient. This is where FAT FINGER comes into play.

Revolutionizing Mobile Asset Tagging with FAT FINGER

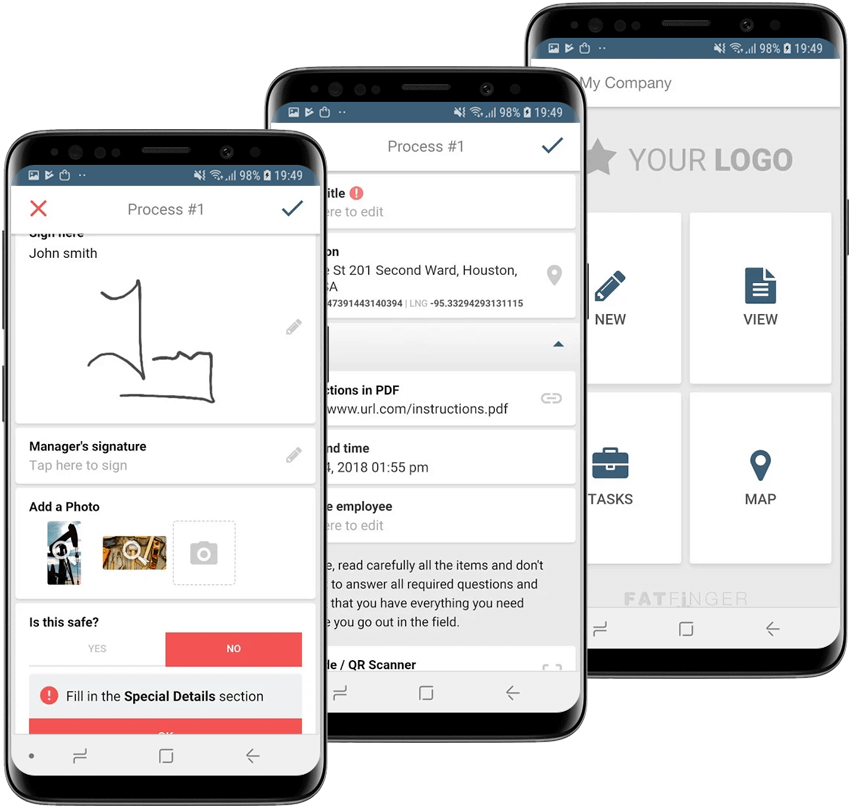

FAT FINGER is a digital workflow procedure builder designed to streamline and automate various processes, including mobile asset tagging. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER transforms the way businesses manage their assets.

Mobile Asset Inspection Workflow

One of the standout features of FAT FINGER is its mobile asset inspection workflow. This feature allows businesses to build mobile asset inspection workflows that help monitor assets accurately and prevent unwanted breakdowns. By leveraging this feature, businesses can:

- Automate asset inspection processes

- Reduce manual errors

- Improve data accuracy

- Enhance asset lifespan

- Boost productivity

With FAT FINGER, businesses can move away from traditional, paper-based asset management methods and embrace a more efficient, digital approach.

Conclusion

A mobile asset tag is a critical aspect of asset management in the oil and gas industry. By leveraging digital workflows and tools like FAT FINGER, businesses can streamline their asset management processes, improve operational efficiency, and boost profitability.

Experience the FAT FINGER Difference

Ready to take your asset management to the next level? Create a mobile asset inspection workflow for free on FAT FINGER today.

Experience the power of digital workflows and mobile asset tagging with FAT FINGER. Request a demo today and see how FAT FINGER can revolutionize your asset management processes.