Asset integrity is a critical aspect of operations in the oil and gas industry. It involves ensuring that the assets are designed, installed, operated, and maintained properly to avoid any operational disruptions, safety hazards, and financial losses. In this digital age, innovative solutions like FAT FINGER are revolutionizing the way companies maintain asset integrity.

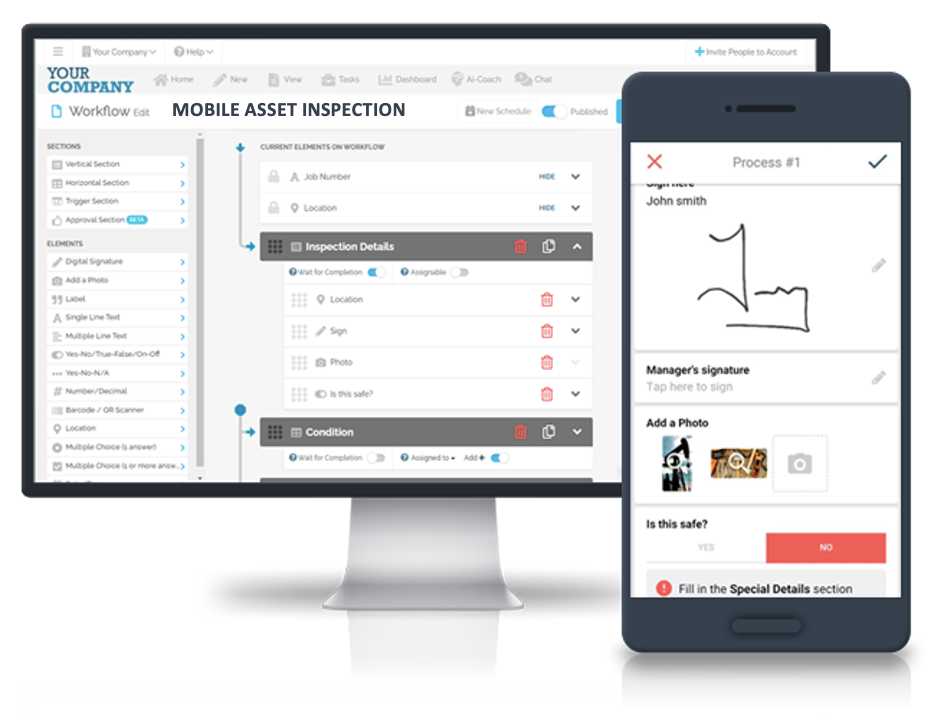

FAT FINGER is a digital workflow procedure builder that offers a range of features including Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching.

This article explores how you can leverage FAT FINGER’s mobile asset inspection workflow to maintain asset integrity in the oil and gas industry.

Request a demo to see how it works.

Understanding the Importance of Asset Integrity

Asset integrity is not just about maintaining the physical condition of the assets. It also involves ensuring that the systems, processes, and people involved in managing the assets are competent and effective. A failure in asset integrity can lead to catastrophic incidents, environmental damage, loss of reputation, and hefty fines. Therefore, maintaining asset integrity is a top priority for oil and gas companies.

The Challenges of Maintaining Asset Integrity

Maintaining asset integrity in the oil and gas industry is fraught with challenges. These include:

- Complex and aging infrastructure

- Harsh operating conditions

- Regulatory compliance requirements

- Workforce competency issues

- Technological advancements

These challenges necessitate the need for a robust and efficient solution like FAT FINGER.

How FAT FINGER Enhances Asset Integrity

FAT FINGER’s mobile asset inspection workflow is designed to help oil and gas companies easily and accurately monitor their assets to prevent unwanted breakdowns. Here’s how it works:

- Drag & Drop Workflow Builder: This feature allows you to create custom workflows for asset inspection. You can easily define the inspection process, assign tasks, set deadlines, and track progress.

- Mobile & Desktop Workflows: FAT FINGER’s workflows can be accessed on both mobile and desktop devices. This means that your field technicians can update the inspection data in real-time, right from the site.

- Dashboards: The dashboards provide a visual representation of the inspection data. You can easily identify trends, spot issues, and make informed decisions.

- Integrations: FAT FINGER can be integrated with your existing systems, ensuring seamless data flow and reducing manual data entry.

- Augmented Reality: This feature enhances the inspection process by overlaying digital information onto the physical world. It can help in identifying issues that are not visible to the naked eye.

- Connect IoT Devices: By connecting IoT devices, you can automate the data collection process and get real-time insights into the condition of your assets.

- Artificial Intelligence Coaching: This feature provides guidance to your technicians during the inspection process, ensuring that they follow the best practices and standards.

By leveraging these features, you can enhance the integrity of your assets, improve operational efficiency, and ensure compliance with regulatory standards.

Case Study: Maintain Asset Integrity with FAT FINGER

Let’s take a look at a case study to understand how FAT FINGER can help in maintaining asset integrity.

A leading oil and gas company was struggling with frequent asset breakdowns, leading to operational disruptions and financial losses. They were using traditional methods for asset inspection, which were time-consuming and prone to errors.

After implementing FAT FINGER’s mobile asset inspection workflow, they were able to streamline the inspection process, reduce errors, and improve the reliability of their assets. The real-time data provided by FAT FINGER helped them in identifying issues early and taking preventive measures, thereby reducing the frequency of breakdowns.

Conclusion

Maintaining asset integrity in the oil and gas industry is a complex task, but with the right tools, it can be made simpler and more efficient.

FAT FINGER’s mobile asset inspection workflow is one such tool that can revolutionize the way you maintain asset integrity. It not only helps in improving the physical condition of the assets but also enhances the systems, processes, and people involved in managing the assets.

So, why wait? Create a mobile asset inspection workflow for free on FAT FINGER and take a step towards enhancing your asset integrity.