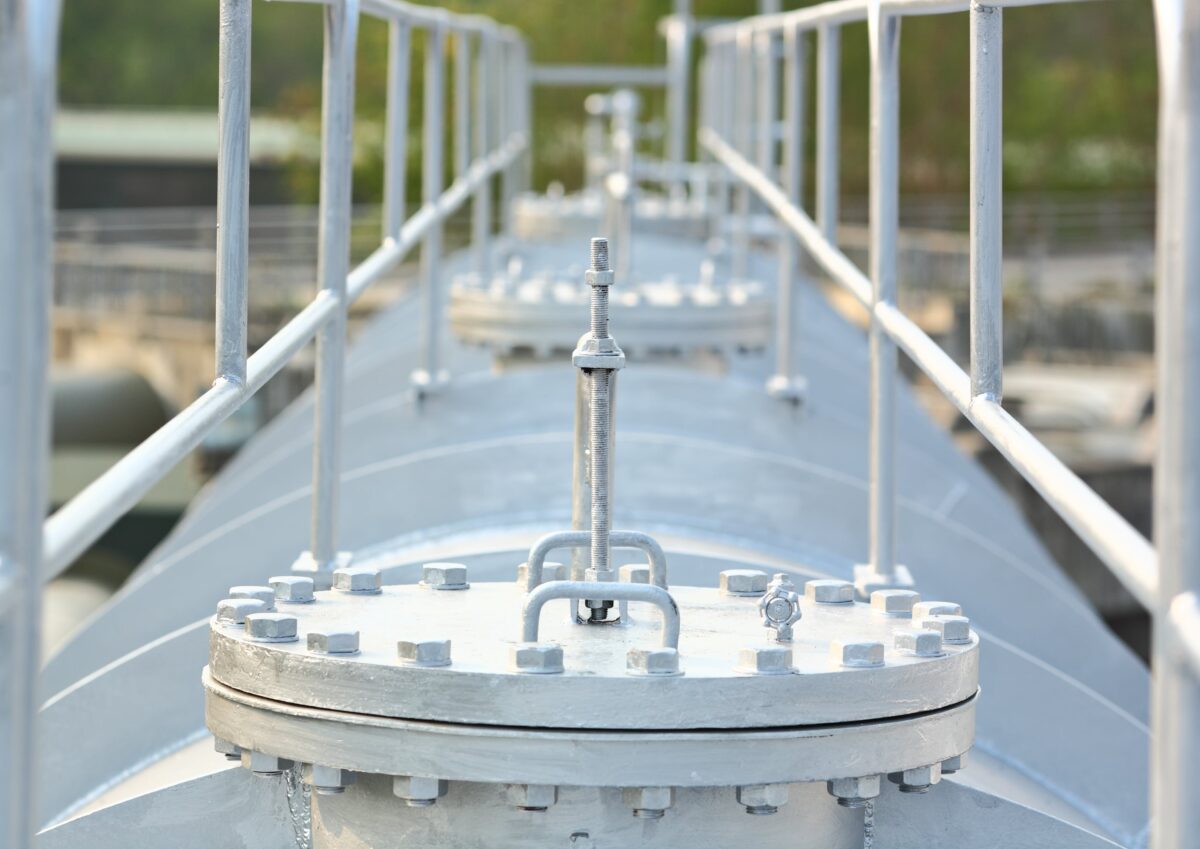

Line changeovers in oil refineries are critical operations that can significantly impact productivity, efficiency, and safety. With the right strategies and tools, such as FAT FINGER, these changeovers can be streamlined to minimize downtime, maximize efficiency, and ensure the highest level of safety. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. In this article, we will explore the best practices for efficient line changeovers in oil refineries and how FAT FINGER can facilitate this process.

Understanding Line Changeovers

Line Changeover, also known as line clearance, is the process of verifying that all line changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality.

Best Practices for Efficient Line Changeovers

Implementing best practices for line changeovers can significantly improve the efficiency and safety of your operations. Here are some strategies to consider:

- Planning and Scheduling: Proper planning and scheduling can significantly reduce downtime during line changeovers. This includes scheduling changeovers during low-demand periods and ensuring that all necessary resources are available.

- Standardization: Standardizing procedures can help reduce errors and improve efficiency. This includes standardizing equipment, processes, and training.

- Training: Regular training ensures that all staff are familiar with the changeover procedures and can perform them efficiently and safely.

- Continuous Improvement: Regularly reviewing and improving changeover procedures can help identify and eliminate inefficiencies.

How FAT FINGER Can Help

FAT FINGER can significantly streamline the line changeover process in oil refineries. Its features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching. With FAT FINGER, you can build digital line clearance procedures to facilitate seamless line changeovers.

Production Managers who have used FAT FINGER have found it to be a game changer for their production line clearance process. They can now streamline their production lines with confidence knowing that everything is right at their fingertips.

Conclusion

Efficient line changeovers in oil refineries are crucial for maximizing productivity, efficiency, and safety. By implementing best practices such as proper planning and scheduling, standardization, regular training, and continuous improvement, you can significantly improve your line changeover process. Tools like FAT FINGER can further streamline this process by providing a platform for building digital line clearance procedures.

Experience the benefits of FAT FINGER for yourself by requesting a demo today. Discover how you can streamline your line changeovers and unlock operational excellence in your oil refinery.

Ready to take your line changeovers to the next level? Sign up for FAT FINGER today and start building your digital line clearance procedures.

Discover the best practices for efficient line changeovers in oil refineries. Learn how to streamline your operations, reduce downtime, and increase productivity. Visit FATFINGER now to get started.