As the manufacturing industry continues to evolve, the need for efficient and effective production processes has never been more critical. One area that often poses a significant challenge is Line Changeover. However, with the right techniques and tools, such as FAT FINGER, it’s possible to significantly reduce line changeover times, leading to improved productivity and profitability.

Let’s delve into the world of lean manufacturing techniques and discover how FAT FINGER can revolutionize your line changeover process. Don’t forget to request a demo to see FAT FINGER in action!

Understanding Line Changeover

Line changeover, also known as line clearance, is the process of verifying that all line changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality.

Lean Manufacturing Techniques for Line Changeover

Lean manufacturing techniques aim to eliminate waste and improve efficiency. When applied to line changeover, these techniques can significantly reduce downtime and increase productivity. Here are some key techniques:

- Standardized Work: This involves creating a standard procedure for line changeover that all employees follow.

- Visual Management: Using visual cues, such as color-coding or signage, can help employees quickly identify what needs to be done during a changeover.

- 5S Methodology: This technique involves sorting, setting in order, shining, standardizing, and sustaining a clean and organized workspace to improve efficiency.

Introducing FAT FINGER

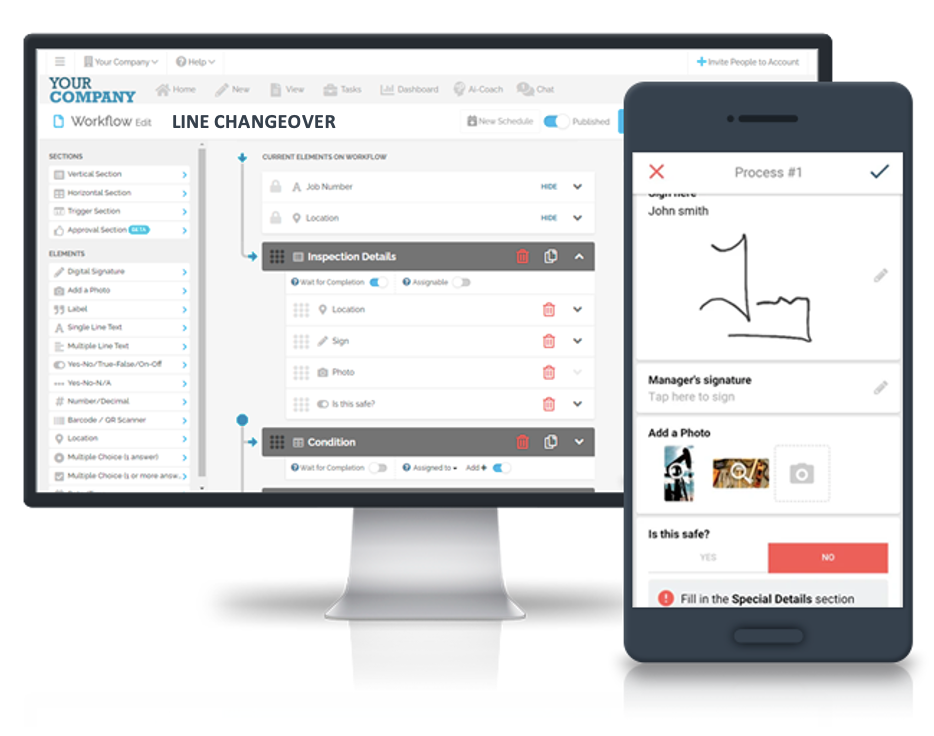

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is a game-changer for line changeover processes.

With FAT FINGER, you can build digital line clearance procedures to facilitate seamless line changeovers. This means reduced downtime, improved line efficiency, and increased product quality. As one Production Manager said, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.”

Benefits of Using FAT FINGER for Line Changeover

Using FAT FINGER for line changeover offers several benefits:

- Reduced Downtime: With streamlined procedures, changeover times can be significantly reduced, leading to less downtime and more production time.

- Improved Efficiency: FAT FINGER’s easy-to-use interface and visual cues make it easy for employees to follow procedures, leading to improved efficiency.

- Increased Quality: By ensuring that all changeover activities are completed correctly, FAT FINGER helps to increase the quality of your products.

Conclusion

Reducing line changeover times is crucial for any manufacturing business looking to improve efficiency and profitability. By implementing lean manufacturing techniques and utilizing tools like FAT FINGER, you can streamline your line changeover process, reduce downtime, and increase product quality. Don’t just take our word for it – sign up for FAT FINGER today and see the difference it can make in your production process.

Ready to revolutionize your line changeover process? Request a demo of FAT FINGER today!

Discover the power of Lean Manufacturing Techniques for Reducing Line Changeover Times. Implement these strategies to streamline your production process, minimize waste, and maximize efficiency. Learn more and start your journey towards lean manufacturing today. Click here to get started.