As industries evolve, the need for efficient, safe, and compliant operations becomes increasingly critical. This is particularly true during shutdowns, where the stakes are high, and the margin for error is slim. In this context, connected work solutions like FAT FINGER are revolutionizing the way businesses operate, ensuring enhanced compliance and safety during shutdowns.

Understanding the Role of Connected Work in Shutdowns

Shutdowns, also known as turnarounds, are planned periods of non-production where routine maintenance, repairs, and inspections are carried out. These periods are crucial for maintaining operational efficiency and safety. However, they can also be fraught with challenges, including compliance issues and safety risks.

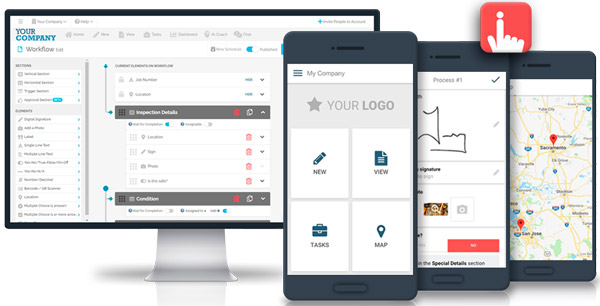

Connected work solutions like FAT FINGER can help mitigate these challenges. By digitizing workflows and procedures, FAT FINGER empowers front-line teams to perform their tasks correctly every time. This not only enhances operational efficiency but also ensures compliance and safety.

How FAT FINGER Enhances Compliance and Safety

FAT FINGER’s features are designed to streamline operations and ensure compliance and safety. Here’s how:

- Drag & Drop Workflow Builder: This feature allows you to create custom workflows that align with your operational needs and compliance requirements.

- Mobile & Desktop Workflows: With FAT FINGER, you can access your workflows from any device, ensuring seamless operations regardless of location.

- Dashboards: FAT FINGER’s dashboards provide real-time insights into your operations, helping you identify and address compliance and safety issues promptly.

- Integrations: FAT FINGER can be integrated with other systems, ensuring a unified approach to compliance and safety.

- Augmented Reality, Connect IoT Devices, Artificial Intelligence Coaching: These advanced features take compliance and safety to the next level by providing interactive guidance and real-time data.

Real-World Applications of FAT FINGER

FAT FINGER’s digital workflows and checklists can be applied across various safety, maintenance, and operations areas. Here are some examples:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

Case Study: Leveraging FAT FINGER for Enhanced Compliance and Safety

Consider a manufacturing company that regularly conducts shutdowns for maintenance. By implementing FAT FINGER, the company was able to digitize its workflows, ensuring that all tasks were performed correctly and in compliance with regulations. The company also leveraged FAT FINGER’s dashboards to monitor operations in real-time, allowing them to promptly address any safety issues. As a result, the company saw a significant reduction in compliance violations and safety incidents during shutdowns.

Conclusion

In today’s fast-paced industrial landscape, ensuring compliance and safety during shutdowns is crucial. Connected work solutions like FAT FINGER can help businesses achieve this by digitizing workflows and providing real-time insights into operations. By leveraging these solutions, businesses can not only enhance compliance and safety but also unlock operational excellence.

Ready to take your compliance and safety to the next level? Sign up for FAT FINGER or request a demo today.