As the oil and gas industry continues to evolve, the need for efficient and effective asset lifecycle management has never been more critical. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence.

The Importance of Connected Work in Oil and Gas Operations

Connected work is a concept that involves the integration of people, processes, and technology to enhance productivity and efficiency. In the oil and gas industry, connected work can significantly improve operational efficiency, safety, and asset lifecycle management.

- Improved Operational Efficiency: Connected work allows for real-time data sharing and collaboration, leading to faster decision-making and improved operational efficiency.

- Enhanced Safety: With connected work, safety procedures such as Take 5 Safety, Near miss reporting, and Incident reporting can be digitized and streamlined, reducing the risk of accidents and improving overall safety.

- Effective Asset Lifecycle Management: Connected work enables better tracking and management of assets throughout their lifecycle, from acquisition to disposal. This can lead to cost savings and improved asset utilization.

Role of FAT FINGER in Connected Work and Asset Lifecycle Management

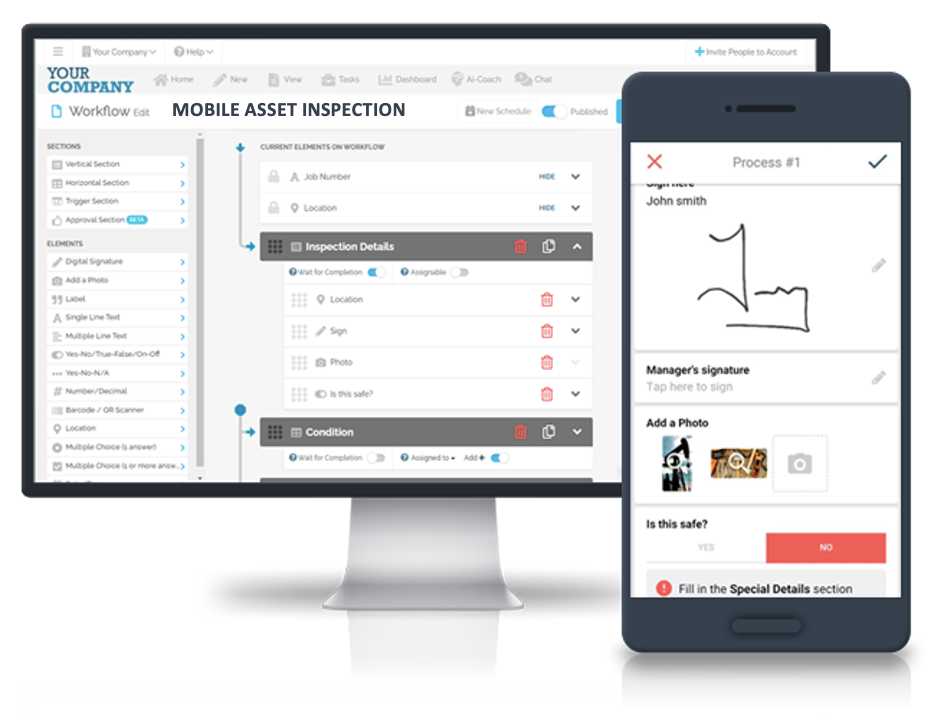

FAT FINGER plays a crucial role in facilitating connected work and asset lifecycle management in oil and gas operations. Its features such as Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching make it a powerful tool for the industry.

- Drag & Drop Workflow Builder: This feature allows you to easily create and customize workflows to suit your operational needs.

- Mobile & Desktop Workflows: With FAT FINGER, you can access and manage your workflows from any device, enhancing flexibility and convenience.

- Integrations: FAT FINGER can be integrated with other systems, allowing for seamless data sharing and collaboration.

- Augmented Reality: This feature enhances the visualization of workflows and procedures, improving understanding and execution.

- Connect IoT Devices: FAT FINGER allows for the integration of IoT devices, enabling real-time tracking and management of assets.

- Artificial Intelligence Coaching: This feature provides intelligent guidance to users, improving the execution of workflows and procedures.

Case Study: FAT FINGER in Action

A leading oil and gas company implemented FAT FINGER to streamline its operations and asset lifecycle management. The company used the Drag & Drop Workflow Builder to create customized workflows for various operations such as Material Inspection, Quality Control, and Shift Handover. The Mobile & Desktop Workflows feature allowed the company’s employees to access and manage these workflows from any device, enhancing flexibility and convenience. The company also used the Connect IoT Devices feature to track and manage its assets in real-time. As a result, the company reported improved operational efficiency, enhanced safety, and effective asset lifecycle management.

Conclusion

Connected work and asset lifecycle management are critical for the success of oil and gas operations. FAT FINGER, with its powerful features, provides an effective solution for implementing connected work and managing assets throughout their lifecycle. Whether it’s improving operational efficiency, enhancing safety, or managing assets, FAT FINGER has got you covered.

Ready to unlock operational excellence in your oil and gas operations? Sign up for FAT FINGER or request a demo today!