Quality Control standards have undergone significant transformations over the years, particularly in the context of global supply chains. This evolution has been driven by the need for improved efficiency, transparency, and accountability in supply chain operations.

In this article, we will explore this evolution and how digital workflow procedure builders like FAT FINGER are revolutionizing the way quality control standards are implemented in global supply chains. Request a demo today to see how FAT FINGER can empower your front-line teams to do their work correctly every time.

The Evolution of Quality Control Standards

Quality control standards have evolved from rudimentary inspection methods to sophisticated, data-driven processes. This evolution has been influenced by technological advancements, globalization, and the increasing complexity of supply chains.

From Inspection to Prevention

Quality control in the early days was primarily focused on inspection. Products were inspected after production, and defective items were discarded. However, this approach was not efficient as it led to waste and did not prevent defects from occurring in the first place. Over time, the focus shifted from inspection to prevention, with an emphasis on designing and controlling the production process to prevent defects.

Globalization and Standardization

With the advent of globalization, companies started sourcing materials and manufacturing products in different parts of the world. This led to the need for standardized quality control procedures that could be applied across diverse locations and cultures. International standards like ISO 9001 were developed to provide a framework for quality management systems.

Technology and Data-Driven Quality Control

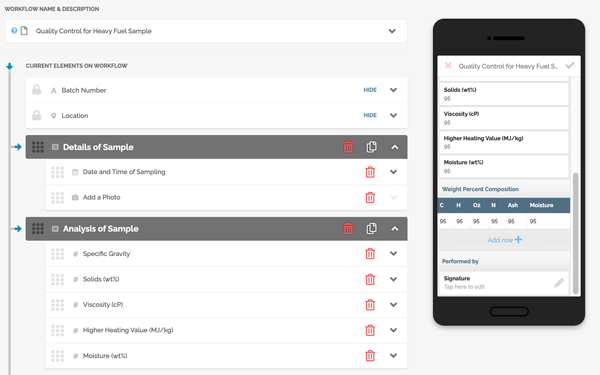

Technological advancements have further transformed quality control standards. Digital tools and technologies like FAT FINGER have made it possible to monitor and control quality in real-time, using data to drive decision-making and continuous improvement.

FAT FINGER: Revolutionizing Quality Control in Supply Chains

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build digital workflow procedures to improve safety and quality in your facility. Here are some powerful checklists you can build with FAT FINGER to boost operational efficiency:

- Material Inspection

- Quality Control

- Shift Handover

- Facility Inspection

- Line Changeover

- Electronic Field Ticket

These checklists enable you to ensure the highest quality standards of your products, reach maximum production potential, modernize your shift transition, ensure your facility keeps running without a hitch, seamlessly transition between processes, and streamline productivity.

Conclusion

The evolution of quality control standards in global supply chains has been marked by a shift from inspection to prevention, the standardization of quality control procedures, and the use of technology and data to drive quality control. Digital workflow procedure builders like FAT FINGER are at the forefront of this evolution, empowering front-line teams to do their work correctly every time and boosting operational efficiency. Build a safety checklist with FAT FINGER today and unlock operational excellence in your supply chain.

Discover how quality control can impact your business. Learn more about the latest trends and strategies to ensure the quality of your products and services. Don’t miss out on this opportunity to stay ahead of the curve. Request A Demo today.