High-volume manufacturing environments are often characterized by complex processes, tight deadlines, and the constant pressure to maintain high-quality standards. Ensuring product quality in such environments can be a daunting task. However, with the right tools and strategies, it is possible to achieve and maintain high-quality standards consistently.

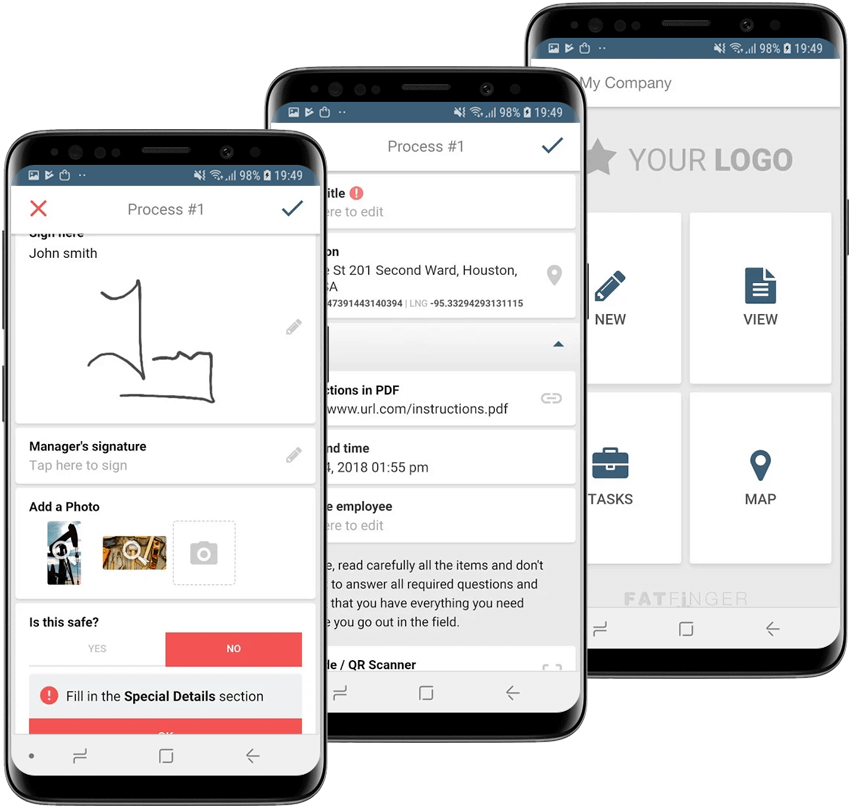

One such tool that has revolutionized the way quality is managed in high-volume manufacturing environments is FAT FINGER. This digital workflow procedure builder empowers front-line teams to do their work correctly every time, unlocking operational excellence. Request a demo today to see how FAT FINGER can transform your manufacturing processes.

The Importance of Quality in High-Volume Manufacturing

Quality is a critical factor in any manufacturing environment. In high-volume manufacturing, the stakes are even higher. A single defect can lead to thousands of faulty products, resulting in significant financial losses and damage to the company’s reputation. Therefore, it is crucial to have robust Quality Control measures in place.

How FAT FINGER Enhances Quality in High-Volume Manufacturing

FAT FINGER offers a range of features that can significantly enhance quality in high-volume manufacturing environments. These include:

- Drag & Drop Workflow Builder: This feature allows you to create custom workflows that suit your specific manufacturing processes. This ensures that every step is followed correctly, reducing the chances of errors and defects.

- Mobile & Desktop Workflows: With FAT FINGER, you can access your workflows from any device, ensuring that your team can follow the correct procedures, no matter where they are.

- Artificial Intelligence Coaching: This feature provides real-time guidance to your team, helping them to avoid mistakes and improve their performance.

Powerful Checklists with FAT FINGER

One of the key ways FAT FINGER enhances quality in high-volume manufacturing is through the use of digital checklists. These checklists can be customized to suit your specific needs and can cover a wide range of processes, including:

- Material Inspection

- Quality Control

- Shift Handover

- Facility Inspection

- Line Changeover

- Electronic Field Ticket

Conclusion

Ensuring product quality in high-volume manufacturing environments is a complex task that requires the right tools and strategies. FAT FINGER offers a range of features that can help you achieve and maintain high-quality standards consistently. With its powerful checklists and other features, FAT FINGER can transform your manufacturing processes, enhancing quality and efficiency. Build a safety checklist with FAT FINGER today and take the first step towards operational excellence.

Ensure the highest quality of your products in high-volume manufacturing environments. Don’t let minor errors escalate into major issues. Take control of your production process today. Request A Demo now and see how our solutions can help you maintain product quality at all times.