Facility inspection checklists are a vital tool for managing your workplace. A well-constructed checklist can help you to identify and correct potential problems before they become serious.

This blog post will discuss the importance of facility inspection checklists and provide a sample checklist you can use in your workplace.

Table of Contents:

1. Why Do You Need to Conduct Facility Inspections?

2. How Frequently Should You Inspect Your Facility?

3. The Components of a Facility Inspection Checklist

4. Efficient Facility Inspection with FAT FINGER

Why Do You Need to Conduct Facility Inspections?

Facility inspections are crucial to keeping any commercial or industrial operation running smoothly and safely. By regularly checking for hazards and inspecting equipment, everyone can help to prevent accidents and improve efficiency. Facility inspections can also help to identify potential problem areas before they cause significant disruptions. In short, regular facility inspections are essential to good facility management.

Everyone is responsible for the safety and well-being of those who work in the facilities they oversee. A crucial part of this responsibility is identifying potential hazards and taking steps to mitigate them. Facility inspections are one way to identify potential hazards.

By looking for evidence of wear and tear, everyone can identify areas where there may be tripping hazards, slippery surfaces, or other dangerous conditions.

In warehouses and manufacturing facilities, Facility managers can also use inspections to identify areas where there may be risks of forklift accidents or other dangers. By taking a proactive approach to hazard mitigation, everyone can help create safer workplaces for everyone.

Regular inspections can also help improve communication between managers and workers, as it allows managers to address concerns and answer questions. In addition, inspections can help to identify potential problems before they become serious, saving both time and money in the long run.

Facility inspection in a warehouse typically focuses on safety hazards, such as trip hazards or blocked exits. Facility inspections can also help identify areas where efficiency can be improved, such as streamlining the flow of traffic in a warehouse. Facility inspection in manufacturing, on the other hand, usually focuses on quality control and process optimization.

Taking a proactive approach to facility inspection can help create safer workplaces for everyone.

How Frequently Should You Inspect Your Facility?

Facility inspections are a crucial part of maintaining a safe and productive workplace. But how often should these inspections take place?

The answer depends on the facility type and the risk level. In general, warehouses and manufacturing facilities should be inspected regularly – at least once per month. However, more frequent inspections may be necessary if there are high levels of traffic or hazardous materials present.

By contrast, offices and retail stores typically don’t need to be inspected as often since there is less potential for accidents or damage. At a minimum, these facilities should be inspected once per quarter.

The Components of a Facility Inspection Checklist

Facility inspections are a critical part of maintaining a safe and functional facility. However, knowing where to start when conducting an inspection can be challenging. Here is an essential checklist of components and areas that should be included in every facility inspection:

– Doors and doorways: Inspect doors and entrances for damage, loose hardware, and trip hazards.

– Floors and floor coverings: Inspect floors for trip hazards, tears in floor coverings, and loose tiles.

– Walls and ceilings: Inspect walls for cracks, holes, or other damage. Also, check for water damage on ceilings.

– Stairs and railings: Inspect stairs and railings for stability and damage. Also, check for loose handrails or missing rails.

– Windows and window coverings: Inspect windows for cracks, holes, or other damage. Also, check window coverings for tears or rips.

– Electrical outlets and switches: Inspect electrical outlets and switches for loose connections or exposed wires.

-Emergency equipment: includes fire extinguishers, sprinkler heads, and alarm systems.

– Plumbing fixtures: Inspect plumbing fixtures for leaks, blocked drains, or damaged pipes.

Following a comprehensive inspection checklist can help keep your facility in good condition and avoid costly repairs or downtime. Regular inspections are an essential part of facility management.

Efficient Facility Inspection with FAT FINGER

Facility inspections are a crucial part of maintaining a safe and functioning environment. A properly conducted facility inspection can identify potential hazards, repair needs, and maintenance issues. However, running an effective inspection can be a time-consuming and challenging process. Traditional paper-based checklist methods are often ineffective, as they are easy to lose and difficult to update.

Assigning tasks with a paper-based checklist is also often counterproductive, as it can be challenging to track who is responsible for what and when tasks need to be completed. Luckily, there is a better way.

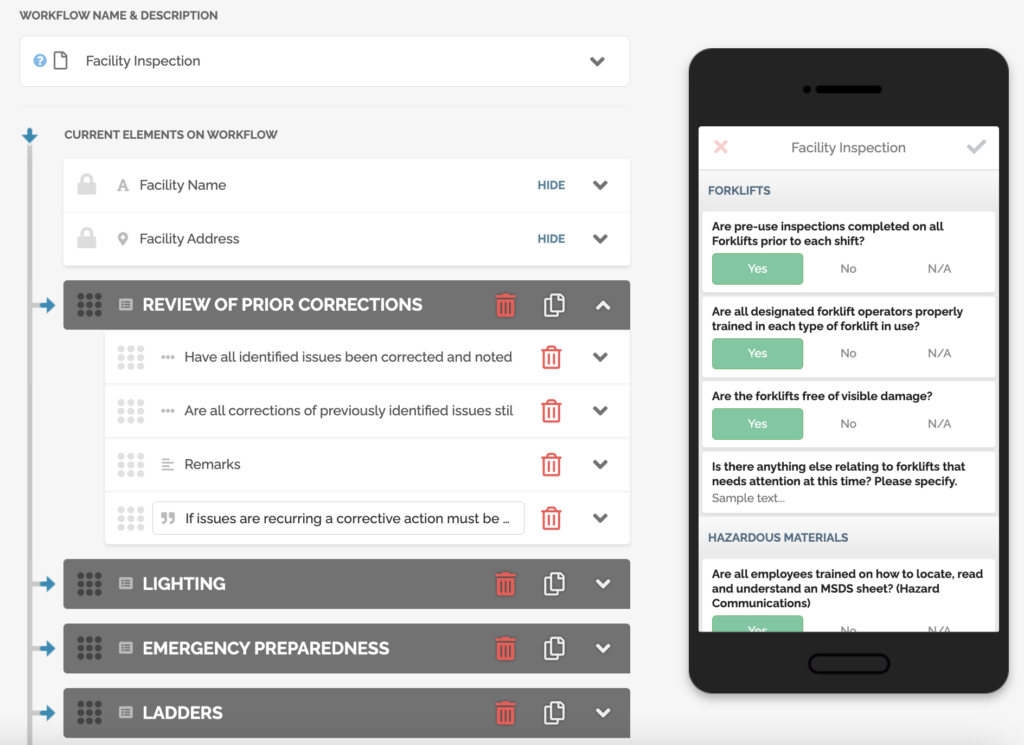

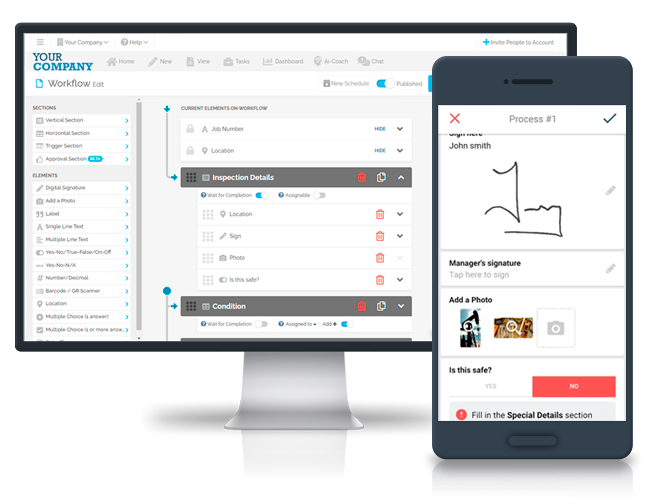

FAT FINGER is a mobile inspection app that helps streamline the facility inspection process and makes it easier to get the job done right. With FAT FINGER, you can create a digital checklist for your facility inspections and assign tasks to specific team members.

Struggling to keep up with your inspections?

FAT FINGER was created to help you overcome these struggles. Our digital checklists:

– Make it easy to access and update the checklist as needed, whenever and wherever

-Create a customized workflow that suits your facility inspection needs. Remarks, corrective actions, and photos collected during inspections can be added to your customized workflow.

-The app also includes features such as automatic report generation that you can send to relevant stakeholders via email, PDF, or web link. This way, everyone can stay up-to-date on the latest information.

-Data collection with the app can give you powerful insight into where your facility inspection stands now and what corrective actions need to be taken.

Make your next facility inspection more efficient and effective by using FAT FINGER! It’s the best way to get the job done quickly and accurately.

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions. Try building your digital procedure on FAT FINGER for free @www.fatfinger.io

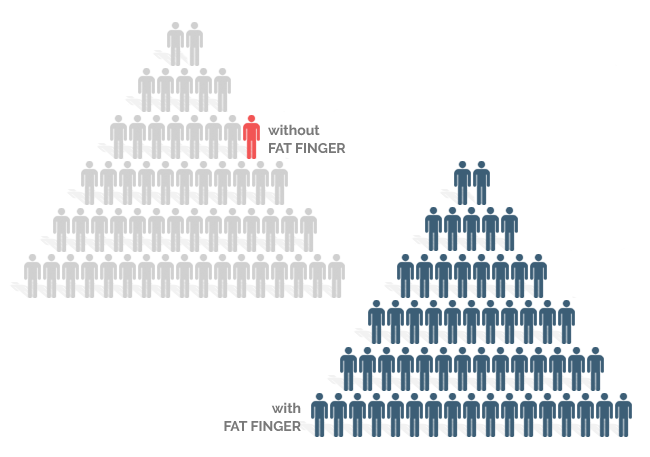

Facility safety hazard reporting made easy for everyone

We empower EVERYONE to initiate and create positive change to improve the company’s safety records. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

Build and customize your facility inspection in seconds

Every site has its own potential hazards. In FAT FINGER you will be able to import different facility inspection processes and make them your own, or simply create one from scratch. And once you are done, you will be able to export your acility inspection workflow to all of your different sites.

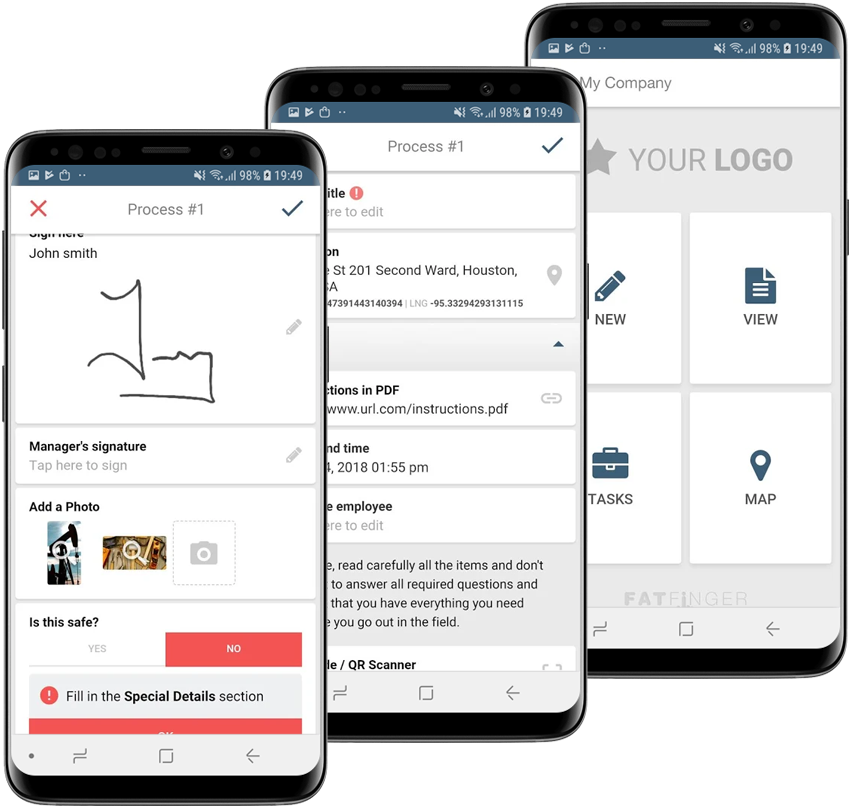

FAT FINGER is a key facility inspection tool

FAT FINGER is the right place where to do all your facility inspection checklists before performing risky tasks out in the field. And also allows any employee to share information in real-time with the entire team, such as photos of a potential hazard.

Safety insights in real-time

Every single piece of information captured by your FAT FINGER users will feed your company analytics in real-time. Adopting FAT FINGER will give you show you the risky points of your operations and how to make them risk-free.