An efficient way to manage your energy consumption starts with understanding how much energy your facility consumes. A detailed energy inspection checklist can help you do

just that by identifying the factors that drive up energy consumption.

Table of Contents:

1. Energy Inspection and Its Purpose

2. Current Challenges in Using Paper-Based Energy Inspection Checklists

3. How Often Should You Conduct an Energy Inspection?

4. Factors Affecting Energy Consumptions

5. Save your Energy Consumption with FAT FINGER

Energy Inspection and Its Purpose

The United States is an industrialized country, as seen in 2021 when the industrial sector accounted for 33% of total U.S. energy consumption. With that said, these large industries need to save energy resources whenever possible. An energy inspection is an assessment of any residential or industrial sector’s energy usage. An energy inspection is a process whereby a trained facility auditor inspects a building and its systems to identify opportunities for energy efficiency improvements.

An energy inspection aims to help a business or organization reduce its energy consumption, save money on utility bills, and become more environmentally sustainable.

Energy inspections typically involve conducting a comprehensive review of a facility’s energy use, evaluating the performance of equipment and systems, and making recommendations for improvements. The audit may include reviewing the building’s HVAC system, lighting, and other electrical appliances. It may also include an assessment of the insulation and weather stripping to ensure that the building is not losing heat or cool air. In some cases, an Energy Manager may also perform on-site testing in order to verify results.

Energy inspections can be performed on commercial and residential buildings and yield significant financial savings for businesses and homeowners alike.

Current Challenges in Using Paper-Based Energy Inspection Checklists

Conducting an energy audit is a critical part of improving the energy efficiency of any property, but it’s also a time-consuming and often tedious process. Even with all the latest tools and technology, conducting an energy audit can still be a pretty laborious process. You have to juggle paper checklists, data collection, and analysis all while trying to keep track of your progress.

A paper-based energy inspection checklist is a tool commonly used in energy audits to assess energy efficiency opportunities. However, there are several disadvantages to using paper-based checklists, which can lead to inaccurate data and energy auditors not being able to identify and prioritize energy optimization measures. This also includes:

1.Paper checklists can be easy to lose or misplace. If a paper checklist is not stored correctly, it can be damaged or destroyed, making it unusable.

2.Paper checklists can be time-consuming to fill out. Energy auditors often have to travel to different locations, and it can take several minutes to complete a paper checklist for each site. This can add up to a significant amount of time over the course of an inspection.

3.Paper checklists can be difficult to read and interpret. Energy inspectors need to be able to identify areas of concern quickly, and a paper checklist can sometimes make this difficult.

4. It can be challenging to track progress on energy optimization measures when using a paper-based checklist, as energy auditors may not have access to real-time data.

Overall, these pain points can make it difficult for energy auditors to properly assess energy efficiency opportunities and make informed decisions during energy inspection. Energy auditors can overcome these challenges by implementing a digital solution that addresses these pain points.

How Often Should You Conduct an Energy Inspection?

Part of energy management is knowing when to conduct an energy inspection. Energy inspections help you to identify areas where your energy use is high and make changes to improve efficiency. Many experts recommend conducting an energy inspection once a year, but the frequency may vary depending on the size and age of your building, your energy use, and other factors.

The first energy audit should be repeated in facilities that experience significant changes to their use. For example:

-Difference in the function of certain work sections. If an entire floor of a building becomes parking and is not used for warehousing anymore, then it would make sense to do another audit so we can see what kind of savings could have been made with better efficiency.

-Replacing old equipment with newer models that consume less electricity. This often happens in manufacturing, where they might have an audit done, then a few years later, they’ve replaced all their old machines with more efficient models.

-After any significant changes to the building envelope. This would include adding insulation, weather stripping, or energy-efficient windows.

-Change in the number of workers utilizing the facility. If the number of employees working in a building decreases by 20 percent, the facility’s energy needs have also reduced.

Generally, it may be concluded that performing an audit on occasion is beneficial as long as potential savings are found at the facility.

Factors Affecting Energy Consumptions

Energy consumption is a critical factor in the operation of industrial sectors. Energy waste can lead to higher production costs and lower profits. Energy-efficient practices can help reduce energy waste. The following are some factors that affect energy consumption in industrial sectors:

-The type of production process being used. Energy-intensive processes such as smelting and chemical production generally require more energy to operate, resulting in higher levels of energy waste. On the other hand, less Energy intensive processes such as fabricating and assembly tend to consume less energy overall.

-The level of technology being used. More energy-intensive processes require more energy input to produce the same amount of output. Newer, more efficient operations typically use less energy and result in lower energy consumption overall. Therefore, energy consumption will naturally decline as the industrial sector’s technology processes improve. This relationship between energy use and technological advancement has been borne out over time as industries have become increasingly energy efficient.

–The efficiency of the equipment being used. One way to assess the efficiency of equipment is to look at the Energy Consumption Index (ECI). This index measures the energy required to operate a piece of equipment over its lifetime. The lower the ECI, the more energy-efficient the equipment. When choosing new equipment for an industrial setting, it is essential to consider the ECI to make the most efficient choice possible.

-The training and skills of the workforce. To minimize energy waste, it is essential that all members of the workforce are adequately trained in the use of the equipment and are aware of energy-saving practices.

-The environmental conditions. Temperature changes can impact the efficiency of equipment and machinery, leading to increased energy consumption. Similarly, humidity levels can affect equipment performance, resulting in increased energy waste. In addition, environmental conditions can also impact the demand for specific products or services, which in turn can affect energy consumption. For example, if there is an increase in demand for air conditioning during a heatwave, this will lead to an increase in energy consumption as businesses seek to meet the increased demand.

-The availability of energy resources. Available energy resources, including fossil fuels, nuclear power, and renewable energy sources, all impact how much energy is consumed in the industrial sector. The availability of energy resources affects both the cost of energy and the potential for environmental damage. When energy resources are scarce or expensive, industries are forced to reduce their consumption. This can lead to increased efficiency and less waste. However, when energy resources are readily available and cheap, industries tend to consume more energy, leading to increased pollution and waste.

Energy-efficient practices can help reduce energy waste and improve the bottom line for industrial sectors.

Save your Energy Consumption with FAT FINGER

Energy management is a top priority for any facility manager looking to reduce costs and improve efficiency. A digital energy inspection checklist is a valuable tool for identifying opportunities for improvement. By systematically going through your facility and evaluating each energy-consuming system, you can make informed decisions about where to invest in energy efficiency upgrades.

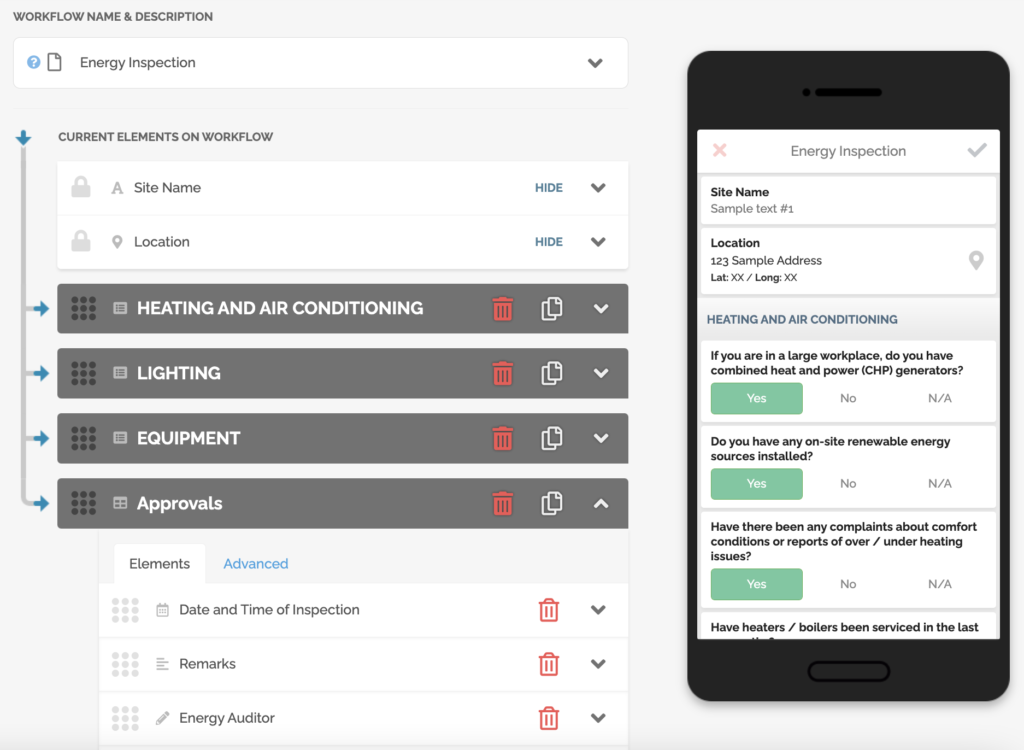

FAT FINGER energy inspection digital workflow makes the process easier than ever. With our intuitive digital workflow, you can quickly collect data and generate professional reports without all the hassle. All these while giving you insights to pinpoint where you are performing and where your next area of focus needs to be.

How can FAT FINGER help?

Intuitive digital workflow – Paperless and Powerful.

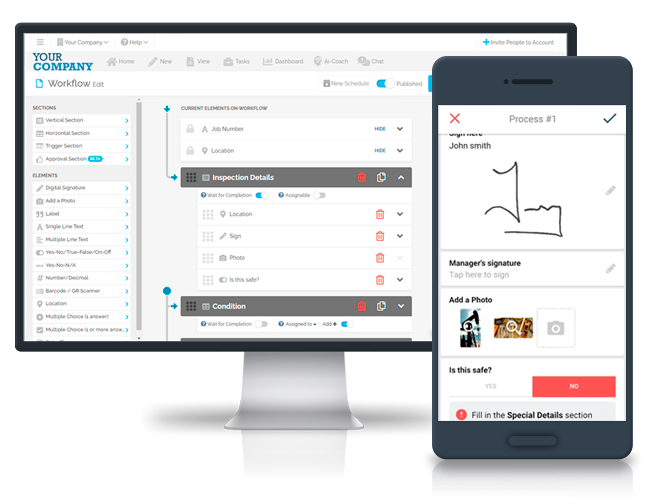

FAT FINGER’s digital energy inspection checklist is designed to streamline the data collection process and make it easy to generate professional reports. With our intuitive workflow, you can quickly customize your data collection with images and video to create workflows with No-Code directly where work is done. Automatically generate reports with one click and share them with stakeholders.

Advanced Analytics- What gets measured gets managed.

FAT FINGER’s digital energy inspection checklist is not only easy to use but also provides you with valuable insights to help improve your facility’s energy efficiency. With our detailed dashboards, you can quickly identify areas of improvement and track your progress over time.

Data powerhouse – Keeping everything in one place.

All your up-to-date work instructions and training content are available across any device as employees perform the work. Data are stored in cloud and available in real-time to everyone who needs it.

Inspections for everyone – Anytime and anywhere.

No matter your location, you can use our digital energy inspection checklist on any device with a web browser or FAT FINGER app. Whether you’re at the job site or in the office, you can easily collect data and generate reports using our user-friendly interface.

Make your next energy inspection more efficient and effective by using FAT FINGER! It’s the best way to get the job done quickly and accurately.

So what are you waiting for? Try FAT FINGER today!

About FAT FINGER:

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

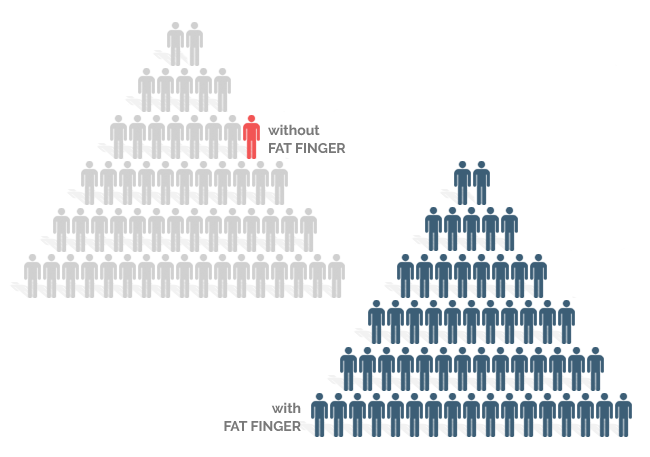

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.Try building your digital procedure on FAT FINGER for free @www.fatfinger.io

Energy reporting made easy for everyone

We empower EVERYONE to initiate and create positive change to improve the company’s energy records. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

Build and customize your energy inspection in seconds

Every site has its own potential hazards. In FAT FINGER you will be able to import different energy inspection processes and make them your own, or simply create one from scratch. And once you are done, you will be able to export your safety workflow to all of your different sites.