As the world shifts towards sustainable energy, the demand for Electric Vehicles (EVs) is skyrocketing. This surge in demand has put immense pressure on manufacturers to not only increase production but also ensure the highest quality standards. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers frontline teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. Request a demo today and see how FAT FINGER can revolutionize your EV manufacturing process.

Quality Control in EV Manufacturing

Quality Control in EV manufacturing is a critical aspect that determines the success of the final product. It involves a series of checks and balances to ensure that every component of the vehicle meets the highest standards of quality and safety.

The Importance of Quality Control

Quality control is not just about producing a good product; it’s about maintaining a brand’s reputation, ensuring customer satisfaction, and most importantly, ensuring the safety of the end-users. A single defect can lead to recalls costing millions and damaging the brand’s reputation.

Quality Control Challenges in EV Manufacturing

Quality control in EV manufacturing presents unique challenges. The complex nature of EVs, with their high-voltage electrical systems and advanced software, requires a more sophisticated approach to quality control. Additionally, the rapid pace of innovation in the EV industry means that quality control processes must be continually updated and improved.

How FAT FINGER Can Help

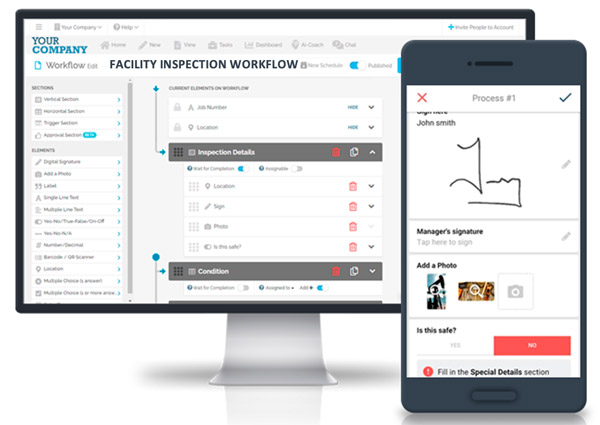

FAT FINGER can help overcome these challenges by providing a platform to build digital workflow procedures that ensure every step of the manufacturing process is carried out correctly. Here are some powerful checklists you can build with FAT FINGER to boost operational efficiency:

- Material Inspection: Ensure the highest quality standards of your products with a digital material inspection. Defects can be identified early in the production process before they become too costly.

- Quality Control: Ensure that what your customers get presents the best of your brand. Reach maximum production potential with customized automated workflow.

- Shift Handover: Modernize your shift transition and watch the savings skyrocket. Automate tedious tasks and keep your entire team in the loop.

- Facility Inspection: Ensure your facility keeps running without a hitch with this effective facility inspection workflow.

- Line Changeover: Get the most out of your production by seamlessly transitioning between processes with our line changeover solution.

- Electronic Field Ticket: Upgrade your ticketing system and save big. Cut out tedious tasks and boost your team’s productivity with automated field reporting, workforce scheduling, and invoicing.

Conclusion

Quality control in EV manufacturing is a complex but crucial process. With the help of FAT FINGER, manufacturers can streamline their quality control processes, ensuring that every vehicle that rolls off the production line meets the highest standards of quality and safety. Don’t let quality control challenges slow down your production. Build a safety checklist with FAT FINGER today and unlock operational excellence in your EV manufacturing process.

Discover the importance of quality control in Electric Vehicle (EV) manufacturing. Ensure the efficiency, safety, and longevity of your EV products. Don’t miss out on the opportunity to enhance your manufacturing process. Request a demo or sign up for a free trial today.