In the world of manufacturing and production, efficiency is key. One of the most critical aspects of this efficiency is the process of Line Changeover or line clearance. This process involves verifying that all line changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality. But how can this process be optimized for different industrial sectors? Enter FAT FINGER.

About FAT FINGER

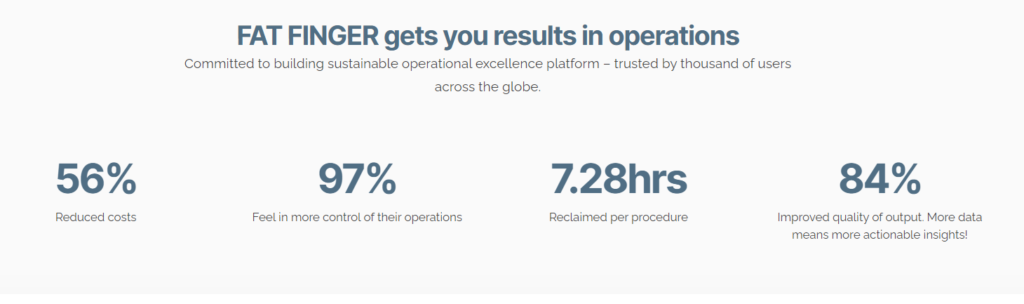

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is revolutionizing the way line changeovers are managed. Production Managers have praised FAT FINGER, stating, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.” Request a demo today to see how FAT FINGER can transform your line changeover process.

Customizing Line Changeover Techniques

Line changeover techniques can vary greatly depending on the specific needs and requirements of different industrial sectors. However, with FAT FINGER, you can build digital line clearance procedures that facilitate seamless line changeovers regardless of your industry. Here’s how:

- Drag & Drop Workflow Builder: This feature allows you to easily create and customize your line clearance procedures. You can add, remove, or rearrange steps as needed to suit your specific process.

- Mobile & Desktop Workflows: With FAT FINGER, you can access your line clearance procedures from any device, making it easy for your team to follow the correct procedures no matter where they are.

- Integrations: FAT FINGER can be integrated with other systems and software, allowing you to streamline your line clearance process even further.

- Augmented Reality: This feature can guide your team through the line clearance process, ensuring that every step is completed correctly.

- Connect IoT Devices: By connecting your IoT devices to FAT FINGER, you can automate certain aspects of the line clearance process, saving time and reducing the risk of human error.

- Artificial Intelligence Coaching: FAT FINGER’s AI coaching can provide real-time feedback and guidance to your team, helping them to improve their line clearance procedures over time.

Benefits of Customizing Line Changeover Techniques

Customizing your line changeover techniques with FAT FINGER can bring a host of benefits to your organization. These include:

- Reduced Downtime: By streamlining your line clearance process, you can minimize downtime and keep your production lines running smoothly.

- Improved Efficiency: FAT FINGER’s features can help to eliminate inefficiencies in your line clearance process, leading to increased productivity and output.

- Increased Product Quality: By ensuring that every step of the line clearance process is completed correctly, you can reduce the risk of errors and improve the quality of your products.

Conclusion

In conclusion, customizing line changeover techniques for different industrial sectors is crucial for maximizing efficiency and productivity. With FAT FINGER, you can easily create and customize digital line clearance procedures that suit your specific needs, leading to reduced downtime, improved efficiency, and increased product quality. Don’t let outdated line clearance procedures hold you back. Sign up for FAT FINGER today and unlock the full potential of your production lines.

Discover how to customize line changeover techniques for different industrial sectors. Learn more about the process, benefits, and how it can improve your business operations. Visit here to get started.