As the Chemical industry continues to evolve, the need for innovative solutions to enhance safety and compliance in hazardous environments has never been greater. One such solution is the use of connected worker solutions, such as FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding Connected Worker Solutions

Connected worker solutions are digital tools that facilitate real-time communication, collaboration, and data sharing among workers, particularly those in hazardous environments. These solutions can significantly enhance safety and compliance in the Chemical industry by providing workers with access to critical information and resources when they need them most.

The Role of FAT FINGER in Connected Worker Solutions

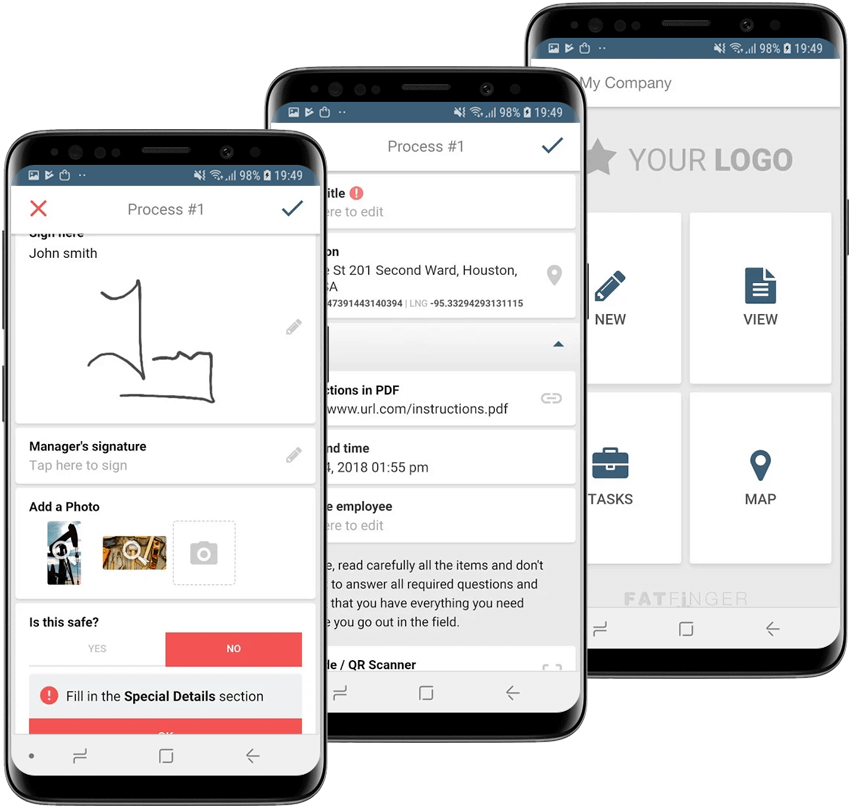

FAT FINGER is a leading provider of connected worker solutions, offering a range of features including a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching. These features enable teams to build checklists, workflows, and digital procedures that unlock operational excellence.

Enhancing Safety with FAT FINGER

FAT FINGER’s safety solutions include:

- Take 5 safety

- Near miss reporting

- JSA / JHA

- Risk Assessment

- Incident reporting

- Journey report

These solutions enable workers to quickly and accurately report safety incidents, assess risks, and take necessary precautions to prevent accidents.

Improving Operations with FAT FINGER

FAT FINGER’s operations solutions include:

- Material Inspection

- Quality Control

- Shift Handover

- Facility inspection / Production rounds

- Line Changeover

- Field ticket

These solutions help to streamline operations, improve quality control, and ensure smooth shift handovers.

Optimizing Maintenance with FAT FINGER

FAT FINGER’s maintenance solutions include:

- Work Order Checklist

- Truck inspection checks

- Mobile Asset Inspection

- Shutdown / Turnaround form

- Preventive maintenance inspection

- Predictive Maintenance

These solutions help to optimize maintenance processes, prevent equipment failures, and reduce downtime.

The Impact of FAT FINGER on the Chemical Industry

By leveraging FAT FINGER’s connected worker solutions, companies in the Chemical industry can significantly enhance safety and compliance in hazardous environments. For example, a recent case study revealed that a chemical company was able to reduce safety incidents by 30% and improve operational efficiency by 20% by implementing FAT FINGER’s solutions.

Conclusion

In conclusion, connected worker solutions like FAT FINGER are revolutionizing the Chemical industry by enhancing safety and compliance in hazardous environments. By providing workers with real-time access to critical information and resources, these solutions can significantly reduce safety incidents, improve operational efficiency, and optimize maintenance processes.

If you’re interested in learning more about how FAT FINGER can help your company enhance safety and compliance, sign up for a demo today.