As the logistics and transportation industry continues to evolve, the need for innovative solutions to enhance Visibility and coordination has never been more critical. One such solution is the use of connected worker solutions, such as FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

The Role of FAT FINGER in Connected Worker Solutions

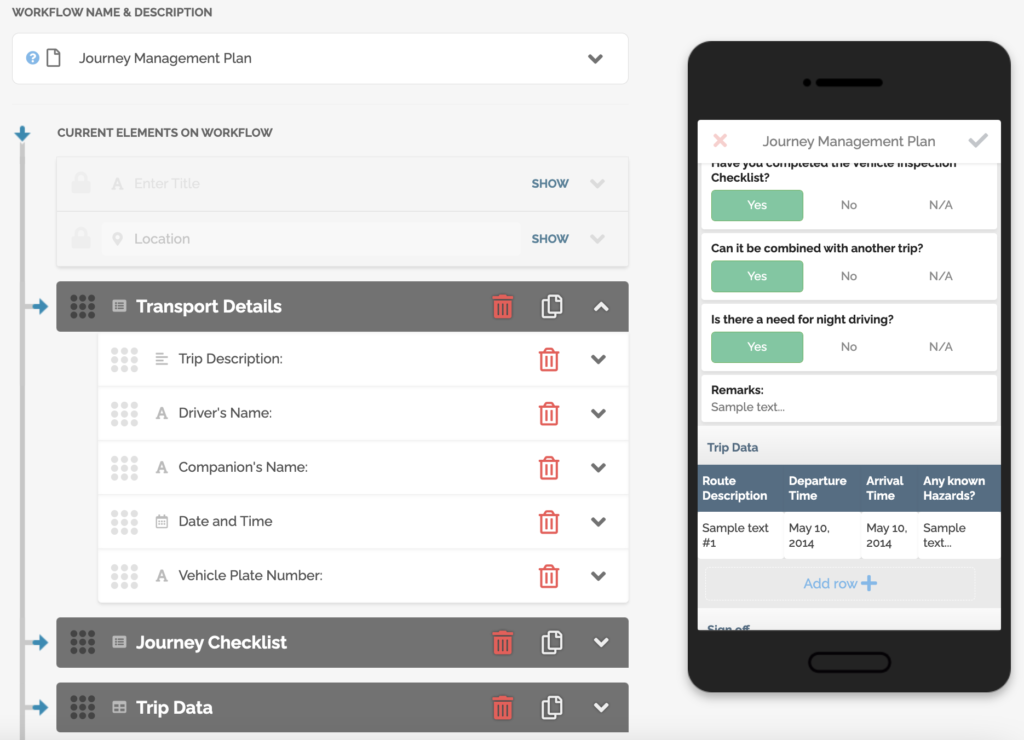

FAT FINGER is a leading provider of connected worker solutions, offering a range of features designed to enhance Visibility and coordination in logistics and transportation. These features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, connect IoT devices, and artificial intelligence coaching.

How FAT FINGER Enhances Visibility and Coordination

FAT FINGER’s digital workflows and checklists can be used across various safety, maintenance, and operations areas. For example,

- Journey Report: This typically refers to a report that is made after a vehicle journey, detailing the route, any hazards encountered, and any incidents that occurred. These reports can be used to assess the safety of certain routes or driving behaviors, and to implement improvements where necessary.

- Risk Assessment: This is a systematic process of evaluating the potential risks that may be involved in a projected activity or undertaking. It involves identifying hazards, assessing the risks associated with those hazards, and determining appropriate ways to eliminate or control the hazards.

- Shift Handover: Shift handover is the process where the responsibilities of a particular job role are transferred from one employee to the other during the change of shifts. The process includes sharing information about tasks completed, pending tasks, issues, or concerns that need attention.

- Truck Inspection Checks: This is a thorough examination of a truck or any other vehicle to ensure it is in good working condition. It includes checking the engine, brakes, tires, lights, wipers, horn, and other parts of the truck. The purpose is to identify any issues or potential problems that could lead to a breakdown or an accident.

Case Study: The Impact of FAT FINGER on Logistics and Transportation

One example of FAT FINGER’s impact on the logistics and transportation industry is its use in a major freight company. The company was struggling with Visibility and coordination issues, leading to delays and increased costs. After implementing FAT FINGER’s connected worker solutions, the company saw a significant improvement in these areas, leading to increased efficiency and reduced costs.

Conclusion

Connected worker solutions like FAT FINGER are revolutionizing the logistics and transportation industry, providing innovative solutions to enhance Visibility and coordination. By leveraging these solutions, companies can significantly improve their operations, leading to increased efficiency, reduced errors, and improved safety.

If you’re interested in learning more about how FAT FINGER can help your logistics and transportation company, sign up for a demo today.