Shutting down your manufacturing operations can be a complicated process. You’ve got a million things on your mind, and it can be challenging to keep track of all the details. That’s why a pre shutdown checklist is essential to ensure a smooth and successful shutdown.

In this blog post, we will cover everything you need to consider for a thorough pre shutdown checklist. Whether you are an engineer, frontline worker, or manufacturer, this checklist will make sure you are covering all your bases before shutting down your operations.

A pre-shutdown is a vital step in the manufacturing process for oil and gas companies. It refers to a planned and temporary shutdown of a plant or facility to allow for essential maintenance, repairs, or upgrades

This ensures that the plant can continue to operate at optimal efficiency, reducing the risk of unexpected shutdowns or downtime. For enterprises in the manufacturing industry, a pre-shutdown is an opportunity to minimize risk and optimize operations. By focusing on preventative measures, companies can save costs and improve safety and reliability. Rushing into a shutdown without proper planning can be incredibly costly and disruptive. That’s why a pre-shutdown strategy is essential for any enterprise in the oil and gas industry.

5 Steps for Effective Pre-Shutdown Process

1. Establish a Clear Plan

Before you begin your shutdown process, you should have a clear plan in place. This plan should outline the proper sequence of steps to ensure the shutdown is performed effectively. Also, establish a timeline for each process so you can prioritize critical tasks first.

2. Assess the Equipment

Your equipment plays a vital role in your manufacturing operation’s success. Properly assessing your equipment ensures that it is in good condition, ready to use, and will not cause any problems during the shutdown.

3. Ensure Proper Cleaning and Maintenance

Proper maintenance before the shutdown is critical. Cleanliness is also essential when it comes to machinery. You don’t want any dirt, debris, or other materials to cause issues during startup again.

Ensure that the necessary routine maintenance work is performed and that the parts are lubricated. Also, make sure the machines are clean and dry, so there is no risk of bacteria growth or mechanical damage.

4. Secure the Facility

Security is of utmost importance during a shutdown. All entries and exits need to be adequately secured and monitored. If necessary, hire additional security personnel to enhance protection.

5. Document Everything

Finally, it is essential to document each step of the shutdown process. Identify all inspection procedures, equipment breakdowns, and detailed work orders. FAT FINGER can help to make this process easier and effective.

Pre-shutdown Checklist with FAT FINGER

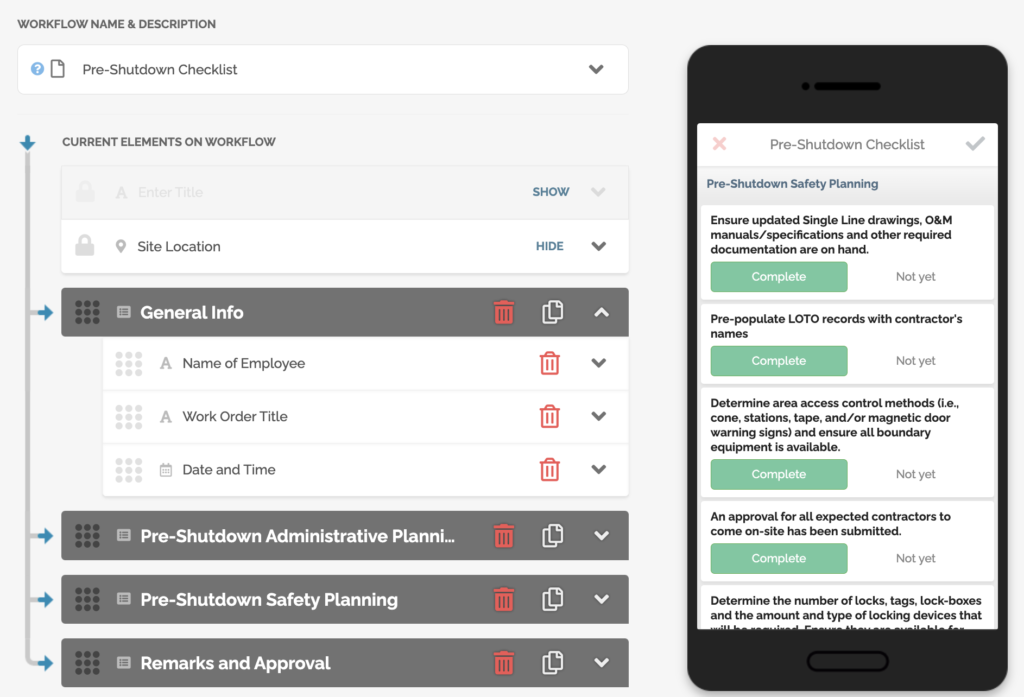

FAT FINGER safety management software is the ideal solution for your pre-shutdown checklist. Our comprehensive digital platform provides you with the tools and resources you need to ensure a successful shutdown.

We understand that shutting down manufacturing operations can be a challenge. But with the right planning, preparation, and organization, you can ensure a smooth and successful shutdown. This pre-shutdown checklist will help you stay on top of all the details to make sure everything runs smoothly.

With easy-to-use dashboard and intuitive interface, it’s never been easier to monitor and manage your pre-shutdown checklists. Keep your operations running smoothly and efficiently with FAT FINGER safety management.

With FAT FINGER, you can rely on a comprehensive and secure digital platform to help you manage every step of the pre-shutdown process.

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io