As manufacturers, we know how critical keeping our electrical systems running smoothly is. Electrical shutdowns, however, are inevitable for maintenance, upgrades, or repairs.

In this blog post, we provide you with an essential electrical shutdown checklist that you can use to make your following shutdown process easy and efficient.

1. Plan your shutdown process ahead of time

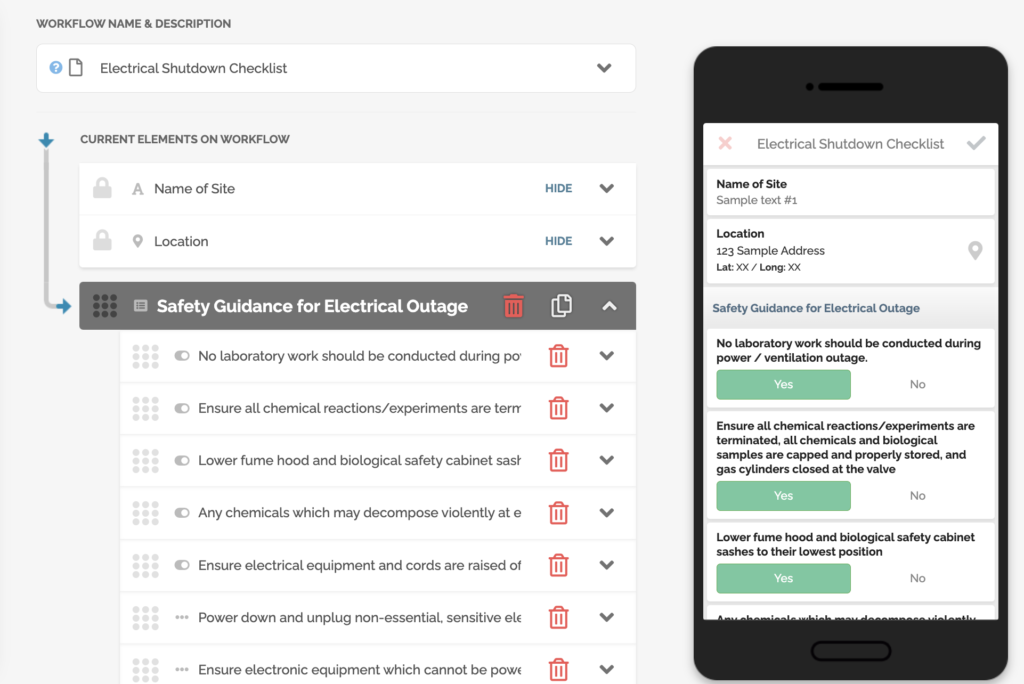

Take time to plan the shutdown process ahead of time. This allows you to communicate with your team members and ensure everyone knows their roles. It also provides you with all the tools, equipment, and supplies required for a successful shutdown. Plan using FAT FINGER electrical shutdown checklist.

2. Conduct an electrical risk assessment

Conducting an electrical risk assessment helps you identify potential safety hazards before the shutdown begins.

Identify potentially hazardous materials, lockout points, and emergency procedures. By doing this, you can create a plan that ensures the safety of your workers and minimizes the risk of accidents.

3. Create a shutdown sequence

Creating a shutdown sequence ensures an organized process that minimizes the potential for mishaps. This procedure should detail the exact sequence in which equipment will be shut down and how long each piece should remain off before the next in line is turned off.

4. Perform electrical testing

Electrical testing before and after a shutdown ensures that your equipment operates efficiently. This should include testing for grounding, power, and voltage fluctuations. It is also helpful to record accurate testing readings for future comparisons.

5. Have a check-in system

Having a check-in system is a crucial part of an electrical shutdown process. This process involves physical checks by responsible team members, ensuring all equipment and machines have been properly turned off and tagged. This step ensures safety for all team members and prevents unnecessary delays due to equipment not being shut down properly.

An electrical shutdown process is a crucial part of a manufacturer’s operations. Manufacturers should follow an electrical shutdown checklist to ensure safe and successful shutdowns. By following these steps, manufacturers can keep their workers safe and their equipment protected during shutdowns.

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io