As the oil and gas industry continues to face unprecedented challenges, resilience has become a critical factor for survival and growth. One of the most effective ways to build resilience is through the adoption of connected work solutions. A prime example of such a solution is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to perform their work correctly every time.

Understanding the Need for Resilience in Oil and Gas Operations

The oil and gas industry is characterized by its volatile nature, with fluctuating prices, regulatory changes, and environmental concerns. These challenges necessitate the need for resilience, which is the ability to adapt and thrive amidst adversity.

Role of Connected Work Solutions in Building Resilience

Connected work solutions, like FAT FINGER, play a pivotal role in building resilience. They streamline operations, enhance safety, and improve maintenance processes, thereby fostering operational excellence.

Streamlining Operations

Connected work solutions enable seamless communication and collaboration among teams, leading to efficient operations. FAT FINGER, for instance, offers solutions like Material Inspection, Quality Control, Shift Handover, Facility inspection/Production rounds, Line Changeover, and Field ticket.

Enhancing Safety

Safety is paramount in the oil and gas industry. FAT FINGER’s safety solutions like Take 5 Safety, Near miss reporting, JSA/JHA, Risk Assessment, Incident reporting, and Journey report help in identifying and mitigating risks, thereby enhancing safety.

Improving Maintenance Processes

Effective maintenance is crucial for the smooth functioning of oil and gas operations. FAT FINGER’s maintenance solutions like Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown/Turnaround form, Preventive maintenance inspection, and Predictive Maintenance ensure that equipment is in optimal condition, reducing downtime and increasing productivity.

Case Study: FAT FINGER in Action

A leading oil and gas company implemented FAT FINGER’s digital workflow solutions and experienced a significant improvement in their operations. The company reported a 30% reduction in downtime, a 20% increase in productivity, and a 15% decrease in safety incidents.

Conclusion: Building Resilience with FAT FINGER

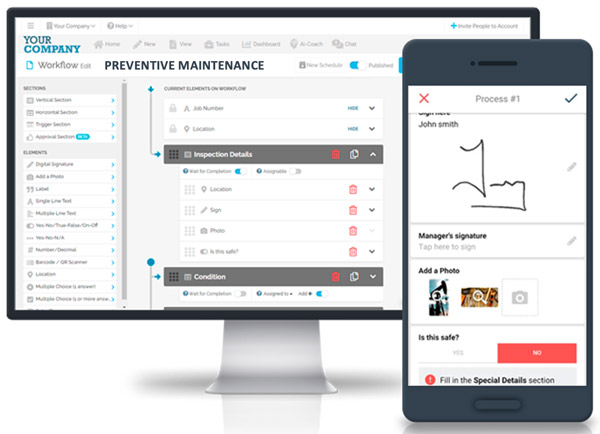

Building resilience in oil and gas operations is no longer an option but a necessity. Connected work solutions like FAT FINGER not only help in building resilience but also unlock operational excellence. With its easy-to-use features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is the ideal partner for oil and gas companies looking to thrive in today’s challenging environment.

Ready to build resilience in your oil and gas operations? Sign up for FAT FINGER or request a demo today.