How many of your frontline workers are using smartphones?

Now imagine subjecting these people, who are used to using a smart device for tasks as simple as noting down a memory, to paper based procedures. They will be slower and less motivated.

This is why you need a digital transformation of your operations from paper-based procedures. Including your standard operating procedures.

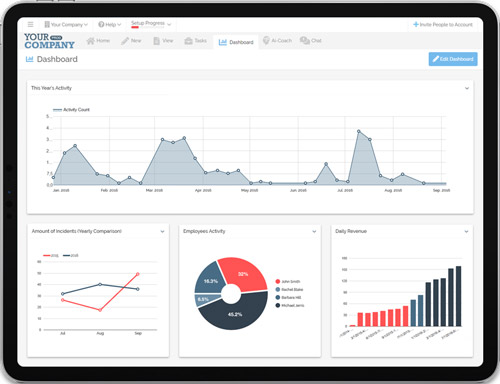

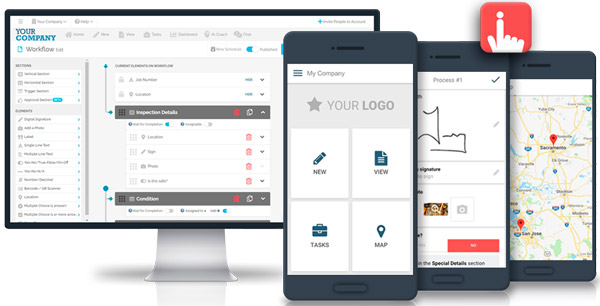

Fortunately, FAT FINGER offers easy and flexible no-code development procedures that you can use to build apps for a myriad of workflows in your facility.

That’s how easy it is to switch from paper based to digital procedures.

In today’s fast-paced and ever-changing business environment, traditional paper-based SOPs no longer suffice. Digital SOPs are becoming increasingly popular due to their ease of access, portability, and traceability.

Even more, they improve the following areas in your organization:

- Efficiency

- Compliance

- Communication

Given the importance of their day-to-day activities, frontline workers require clear and concise guidance on how to perform their tasks effectively, safely and efficiently.

1 – Increased Efficiency

Digital SOPs can greatly increase efficiency for frontline workers, which is crucial for ensuring that tasks are completed accurately and timely.

By having digital SOPs, workers can quickly reference the procedures they need to follow without wasting time searching through paper documents or asking colleagues for help.

All they need to do is fire up the app you created using FAT FINGER and access all the procedures for specific operations through machine learning technology.

Specific areas where operational efficiency can be increased include:

Onboarding

Digital SOPs can greatly enhance the efficiency of the onboarding process by providing structures and accessible resources for new employees.

Here’s how:

- Standardization: They enable organizations to establish standardized onboarding procedures, ensuring that all new employees receive consistent training and information.

For example, a company might have a digital SOP that outlines the step-by-step process for setting up a new employee’s workstation, including installing software, connecting to the network, and accessing necessary resources.

This standardization ensures that each new hire goes through the same onboarding steps, reducing inconsistencies and minimizing errors.

- Centralized and accessible information: Digital SOPs provide a centralized repository of information that new employees can easily access.

For instance, an organization may have a digital platform where new hires can access digital SOPs related to company policies, HR procedures, or operational processes.

By having all the relevant information in one place, new employees can quickly find the resources they need without searching through physical documents or relying heavily on their colleagues.

- Self-paced learning: They allow new employees to learn at their own pace. They can refer to digital resources as often as needed, ensuring a comprehensive understanding of the processes.

Take an oil and gas company for example, it might have digital SOPs with drilling guidelines and best practices. New frontline workers can explore these resources at their own speed, reviewing documentation, and experimenting in a controlled environment.

This self-paced learning approach accommodates different learning styles and promotes a deeper understanding of the material.

- Multimedia integration: Digital SOPs can incorporate multimedia elements, enhancing comprehension and skill development.

Case in point, a manufacturing company might utilize videos within their digital SOPs to demonstrate how to operate machinery safely. New employees can watch these videos to understand the correct procedures, ensuring they are aware of potential hazards and reducing the risk of accidents.

The visual and auditory aspects of multimedia content can make it easier to grasp complex concepts and retain information effectively.

- Real-time updates and collaboration: Digital SOPS can be updated in real-time, ensuring that new employees have access to the most current information and workflow procedures.

For example, an oil and gas company may have a digital SOP regarding compliance training. When there are updates to the regulations, the SOP can be immediately revised to reflect the changes, ensuring that new employees are aware of the latest requirements.

Even more, digital SOPs often allow for collaboration and feedback features, enabling new hires to ask questions or provide suggestions directly within the system, promoting a dynamic and interactive onboarding process.

These benefits optimize the onboarding process, ensuring consistent training, enhancing knowledge retention, and fostering a smoother transition for new employees.

The following table compares different factors that Digital SOPs enhance in an organization during onboarding.

| Factors | Traditional Onboarding | Onboarding With Digital SOPs |

| Time Required | Takes several weeks or even months | Takes only a few days to a week |

| Resources Required | Large team to handle paperwork, training materials, and face-to-face sessions | Only a small team is needed to manage the digital SOPs |

| Effectiveness | Onboarding may not be consistent and can depend on the trainer | Consistent training experience is guaranteed for all trainees |

| Cost | Expensive due to training and materials | Significantly cheaper as it requires fewer materials and resources |

Training

Frontline workers need consistent training to perform their jobs effectively and safely. However, traditional methods of training, such as paper-based manuals and face-to-face sessions, may not be feasible or cost-effective, especially for workers in remote locations or with varying schedules.

Moreover, these methods may not ensure that all employees receive the same level of training or retain the information over time.

Digital standard operating procedures offer a solution to this challenge by providing consistent training that is accessible, interactive, and trackable. With FAT FINGER’s digital SOPs, organizations can create customized training modules that cater to different learning styles and job roles.

For instance, they can include videos, animations, infographics, quizzes, and interactive scenarios that simulate real-life situations. These modules can be accessed online or via mobile applications, allowing workers to complete them at their own pace and convenience.

Digital SOPs can also track employee progress and performance, providing managers with valuable insights into the effectiveness of the training and identifying any knowledge gaps or compliance issues.

This information can be used to improve the training content, adjust the delivery methods, and recognize high-performing workers.

Digital SOPs also reduce the need for repeated training sessions, saving time and resources for both employees and employers.

Workers can refer to the digital SOPs whenever they need guidance or reminders, without having to search through paper-based documents or wait for a supervisor’s assistance.

Altogether, digital SOPs enable organizations to provide consistent and effective training to their frontline workers, ensuring that they are equipped with the skills and knowledge to perform their tasks safely and efficiently.

By leveraging the latest technology and best practices, organizations can create a culture of continuous learning and improvement, empowering their employees to deliver high-quality services and products.

Top Tip: Embrace technology in training—use a mix of videos, quizzes, and interactive scenarios to enhance engagement and improve knowledge retention.

Troubleshooting

This plays a crucial role in an organization as it involves identifying, analyzing, and resolving issues or problems that arise in various aspects of the operation.

Digital SOPs provide a wealth of information that can be analyzed to gain insights into user behavior, performance, and results. This data-driven approach enables organizations to identify areas for improvement, optimize processes, and improve outcomes for safe work practices.

The areas include:

- Problem resolution: Troubleshooting aims to identify and resolve issues, minimize disruptions, and maintain smooth operations. Digital SOPs can greatly benefit problem resolution by providing standardized procedures and step-by-step instructions for troubleshooting various issues.

For example, a manufacturing facility may have digital SOPs outlining the troubleshooting steps for common software or hardware problems. These SOPs can include detailed troubleshooting flows, error interpretations, and recommended solutions.

By having digital SOPs readily available, employees can efficiently follow the prescribed troubleshooting process, enabling faster problem resolution.

- Minimizing downtime: Troubleshooting helps reduce the duration and impact of technical failures or system malfunctions, minimizing downtime by providing quick access to troubleshooting procedures and solutions.

For instance, a manufacturing facility may have digital SOPs that outline the steps to resolve performance issues. When such issues arise, employees can refer to the digital SOPs to identify the root cause and apply the appropriate troubleshooting techniques.

By minimizing the time spent on troubleshooting and resolving issues, digital SOPs help reduce downtime and ensure continuous operations.

- Optimization and continuous improvement: Troubleshooting identifies performance-related issues and provides opportunities for process optimization, system upgrades, and employee training to enhance overall efficiency. Digital SOPs facilitate loops and collaborative features.

For example, a manufacturing company may have digital SOPs for troubleshooting equipment malfunctions. If an employee discovers a more efficient troubleshooting technique or a new solution, they can provide feedback within the digital platform.

This feedback can then be used to update and improve the digital SOPs, ensuring that the organization benefits from the collective knowledge and ongoing enhancement.

Overall, digital SOPs can provide a powerful tool for improving the effectiveness and efficiency of frontline workers.

With the ability to provide consistent training, comply with regulatory requirements, enhance communication, and provide valuable data insights, digital SOPs are a valuable investment for any organization looking to optimize its processes and improve outcomes.

FAT FINGER is especially effective in providing frontline workers with easy, fast, and flexible digital procedures that drive operational excellence.

“I wish I had this for our project progress reports, it would save us so much time. It’s WAY easier than our current Take 5 paper flip books.”

— Aurecon Engineer

2 – Improved Compliance

Digital standard operating procedures can significantly improve compliance for frontline workers, ensuring that workers adhere to standard procedures for safety, quality control, and regulatory purposes.

By providing a clear and accessible guide on how to perform specific tasks, digital SOPs reduce the risk of errors, accidents, and non-compliance. Moreover, they can help to identify potential risks and hazards in advance, providing essential guidance to prevent incidents.

For example, a digital SOP for handling hazardous materials in a manufacturing plant can include detailed instructions on how to properly store, handle, and dispose of these materials.

The SOP can outline safety measures, protective equipment requirements, and compliance procedures to ensure that front-line workers follow the correct processes and maintain compliance with safety and environmental regulations.

The accessibility of digital SOPs further enhances compliance. Front-line workers can access the SOPs through mobile devices, tablets, or dedicated platforms, making them readily available at the point of need.

This is made possible on FAT FINGER, by our apps’ ability to be hosted on any device. This ensures that workers can quickly refer to the SOPs during task execution, reducing the likelihood of non-compliance due to reliance on memory or outdated printed documents.

Digital SOPs can also help keep organizations updated with the latest regulations and compliance requirements, by ensuring that workers have access to the most up-to-date information and procedures.

This is particularly relevant in industries such as healthcare, food safety, and manufacturing, where complying with regulations is critical for the safety of people and the environment.

Take the healthcare industry for example, digital SOPs can be used to keep up with changing medical protocols or privacy regulations.

If there are updates to patient data protection guidelines, the digital SOPs can be revised to include the necessary procedures for handling and securing patient information. Frontline workers can then be notified of the updates and access revised SOPs to ensure compliance.

Overall, digital SOPs offer more than just efficiency gains; they provide a valuable tool for ensuring compliance, reducing risk, and maintaining quality standards.

By implementing digital SOPs, organizations can reduce errors, improve worker safety, and comply with regulations, ultimately contributing to better outcomes and customer satisfaction.

“I’m glad we found such an efficient solution for our work order processes. Thanks to FAT FINGER, our workflow is now running smoother than ever before. Highly recommended!”

— Emma Wilson, Continuous Improvement Specialist

3 – Enhanced Communication

It is easier to communicate digitally than with paper. Just create an app on FAT FINGER that collects all the information you want from your frontline workers, and requests them to fill it in real-time.

More importantly, Digital SOPs enhance communication among frontline workers by providing clear instructions, feedback, and shared knowledge.

Clear Instructions

Digital SOPs offer frontline workers clear and standardized instructions for performing their tasks. These instructions are readily available through digital platforms, ensuring consistency in communication.

Frontline workers can access the SOPs to understand the precise steps, procedures, and best practices associated with their roles. Clear instructions reduce ambiguity and misinterpretation, fostering effective communication and ensuring that everyone is on the same page regarding task execution.

For example, in an oil and gas setting, digital SOPs can provide clear instructions on how to process transactions or manage inventory. These instructions outline specific guidelines and protocols that frontline workers can follow to ensure consistency in operational procedures.

Did You Know? Digitally-enhanced communication reduces ambiguity and fosters a collaborative environment where frontline workers can contribute their own insights and ideas.

Feedback and Evaluation

Digital SOPs can incorporate feedback mechanisms, allowing frontline workers to provide input, and suggestions, or report issues related to the SOPs. This feedback loop enhances communication by giving workers a platform to share their experiences, observations, and recommendations for improving procedures.

It creates a collaborative environment where workers can contribute to the refinement of instructions and the identification of potential areas for improvement.

For instance, if a frontline worker encounters challenges or identifies a more efficient way of performing a task, they can provide feedback through the digital SOP platform.

This feedback can be reviewed by supervisors or relevant teams, leading to iterative improvements in the SOPs and better communication of optimized procedures to all frontline workers.

Industry Insight: According to a survey by PwC, over 60% of employees said they would like to hear feedback on a weekly or even daily basis. Digital SOPs can help meet this demand, ensuring constant improvements and adaptations to your workflow.

Shared Knowledge

Digital SOPs serve as repositories of shared knowledge within an organization. They provide a centralized platform where frontline workers can access and contribute to a collective pool of knowledge, experiences, and best practices.

By sharing their insights and lessons learned, frontline workers can support one another, promote collaboration, and enhance overall communication within the organization.

For example, digital SOPs may have a comment or discussion section where frontline workers can share their tips, troubleshooting techniques, or alternative approaches to tasks. This shared knowledge benefits the entire team by fostering a learning culture, encouraging open communication, and enabling continuous improvement.

Even more, digital SOPs can include features like forums, chat functions, or collaborative spaces, allowing frontline workers to interact, seek clarification, or share expertise. These communication tools promote engagement and facilitate real-time discussions among workers who may be geographically dispersed or working different shifts.

With traditional paper-based SOPs, communication often relies on verbal instructions and feedback, which can be prone to error and misinterpretation.

Ultimately, communication is essential for frontline workers to work efficiently and maintain high-quality standards. Digital SOPs provide a platform for effective communication and collaboration, helping frontline workers to stay connected and informed.

“Gives people information right away, in real time. And provides transparency across the organization.”

— Laurie Campbell, Verified Customer

Adopt Digital SOPs

Digital standard operating procedures (SOPs) powered by enterprise mobility and workforce management solutions have become essential tools for frontline workers in various industries.

These digital SOPs enable organizations to increase efficiency, improve compliance, enhance communication, automate optimization processes, manage incidents effectively, and maintain quality control standards.

Implementing digital SOPs with the help of solutions like FAT FINGER offers organizations the flexibility and ease-of-use necessary to transition from traditional paper-based procedures.

By embracing digital SOPs, organizations can unlock the benefits of enterprise mobility, streamline workforce management, optimize automation processes, improve incident management, and ensure consistent quality control across operations.

Upgrade your organization’s performance by adopting digital SOPs today. Leverage the power of FAT FINGER’s user-friendly and flexible digital procedures to transform your workflows and enhance your workforce’s productivity and effectiveness.

Share on LinkedIn