As the Energy Sector continues to evolve, companies are constantly seeking innovative ways to improve Efficiency, Safety, and productivity. One such innovation that is making waves is Augmented Reality (AR). This technology, when combined with a powerful digital workflow procedure builder like FAT FINGER, can revolutionize Maintenance and Training in the Energy Sector.

Understanding Augmented Reality

Augmented Reality is a technology that overlays digital information onto the real world, enhancing the user’s perception and interaction with their environment. It can be used to provide real-time data, visual instructions, and even Remote Assistance, making it a valuable tool for Training and Maintenance.

The Role of FAT FINGER

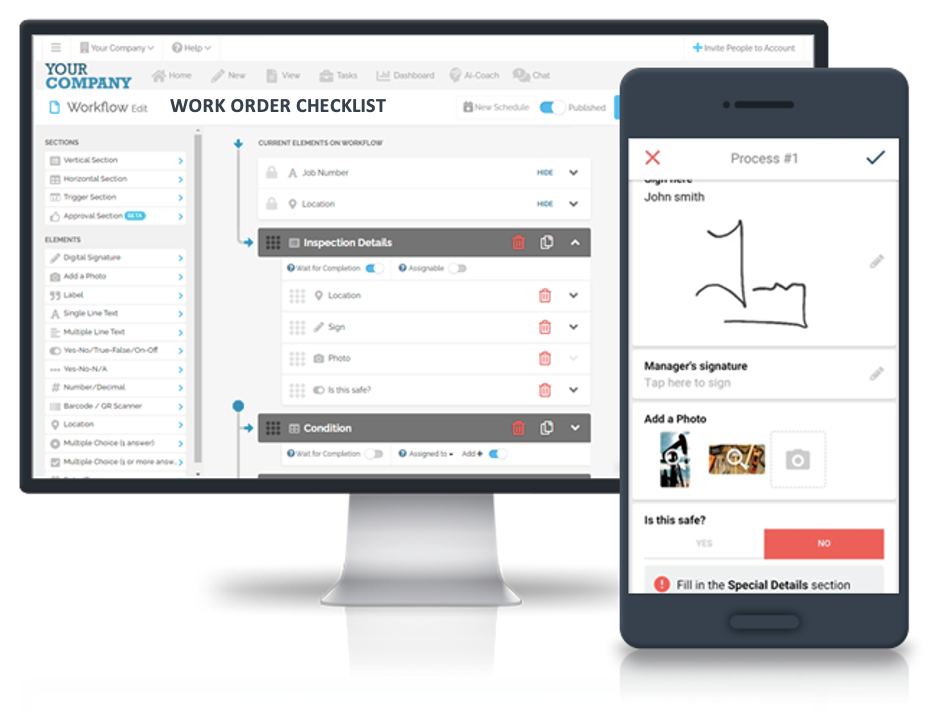

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, Augmented Reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is a comprehensive solution for Safety, Maintenance, and operations in the Energy Sector.

Augmented Reality in Maintenance

AR can significantly enhance Maintenance procedures in the Energy Sector. For instance, it can provide technicians with real-time data and visual instructions overlaid on their field of view, reducing the need for manuals or off-site expert assistance. This can lead to faster, more accurate repairs and less downtime.

- Work Order Checklist: With FAT FINGER, you can create a digital work order checklist that can be enhanced with AR. This can guide technicians through complex procedures, ensuring that every step is completed correctly.

- Predictive Maintenance: AR can also be used for predictive Maintenance. By overlaying data from IoT devices onto the real world, technicians can identify potential issues before they become serious problems.

Augmented Reality in Training

AR can also revolutionize Training in the Energy Sector. By providing a hands-on, Interactive Learning experience, AR can improve knowledge retention and skill development.

- Safety Training: With FAT FINGER, you can create digital Safety procedures that can be enhanced with AR. This can provide trainees with a realistic, immersive learning experience, improving their understanding of Safety protocols.

- Operations Training: AR can also be used to train operators on new equipment or procedures. By overlaying digital instructions onto the real world, trainees can learn by doing, leading to faster skill acquisition.

Case Studies and Statistics

Several companies in the Energy Sector have already started using AR for Maintenance and Training, with impressive results. For instance, a study by the Aberdeen Group found that companies using AR for Training saw a 30% reduction in Training time and a 90% improvement in first-time fix rates for Maintenance tasks.

Another case study involves a major oil and gas company that used AR to train its operators on a new piece of equipment. The company reported a 75% reduction in Training time and a significant improvement in operator performance.

Conclusion

Augmented Reality, when combined with a powerful tool like FAT FINGER, can revolutionize Maintenance and Training in the Energy Sector. By providing real-time data, visual instructions, and an Interactive Learning experience, AR can improve Efficiency, Safety, and productivity. As more companies start to realize the benefits of this technology, it’s clear that AR is not just a passing trend, but a game changer for the Energy Sector.

Ready to take your Maintenance and Training procedures to the next level? Sign up for FAT FINGER or request a demo today and discover how our digital workflow procedure builder can empower your front-line teams to do their work correctly every time.