Safety is crucial to any manufacturing process. As a safety engineer or a frontline worker, you know how important it is to identify and prevent workplace hazards. One of the ways to enhance safety in the manufacturing industry is through near miss-reporting.

Near miss-reporting refers to reporting a safety incident that could have resulted in an injury but fortunately did not. In this blog post, we’ll explore the benefits of near-miss-reporting and why it should be an essential part of any manufacturing safety program.

1. Enhances Safety Awareness

Reporting near misses encourages workers and management to become more aware of potential hazards at the workplace. Every near-miss report is an opportunity to identify and address potential safety hazards before they lead to an injury. Workers become more conscious of their surroundings and are more likely to report any suspicious occurrences that could lead to an accident.

2. Promotes Continuous Improvement

Near miss-reporting helps to identify patterns and trends over time, enabling manufacturers to improve their processes continually. By analyzing these reports, manufacturers can determine if recurrent problems or unsafe practices need attention.

3. Creates a Proactive Safety Culture

Near miss-reporting promotes a safety-first culture by encouraging workers to take proactive steps to prevent injuries. Workers are more likely to report near misses if they believe that their information will be used to enhance safety rather than blame them for the incident.

4. Saves Time and Minimizes Costs

Near miss-reporting saves valuable time and resources by identifying potential hazards that could have resulted in costly accidents. Addressing these hazards before they lead to an injury can significantly reduce the costs associated with compensation claims, lost productivity, and insurance premiums.

Moreover, taking corrective actions based on near miss-reports is more cost-effective than addressing the aftermath of a severe incident.

5. Improves Regulatory Compliance

Near miss-reporting is an essential component of regulatory compliance and can help manufacturers meet the requirements of various standards and regulations. Some regulations stipulate that employers must report near misses and provide detailed information regarding corrective actions taken. Meeting regulatory requirements not only keeps manufacturers in compliance but also enhances safety in the workplace.

As a safety engineer or frontline worker, it is essential to prioritize near-miss-reporting as part of an overall manufacturing safety program. Incorporating miss-reporting into safety procedures enhances safety and drives continuous improvement in the workplace.

About FAT FINGER

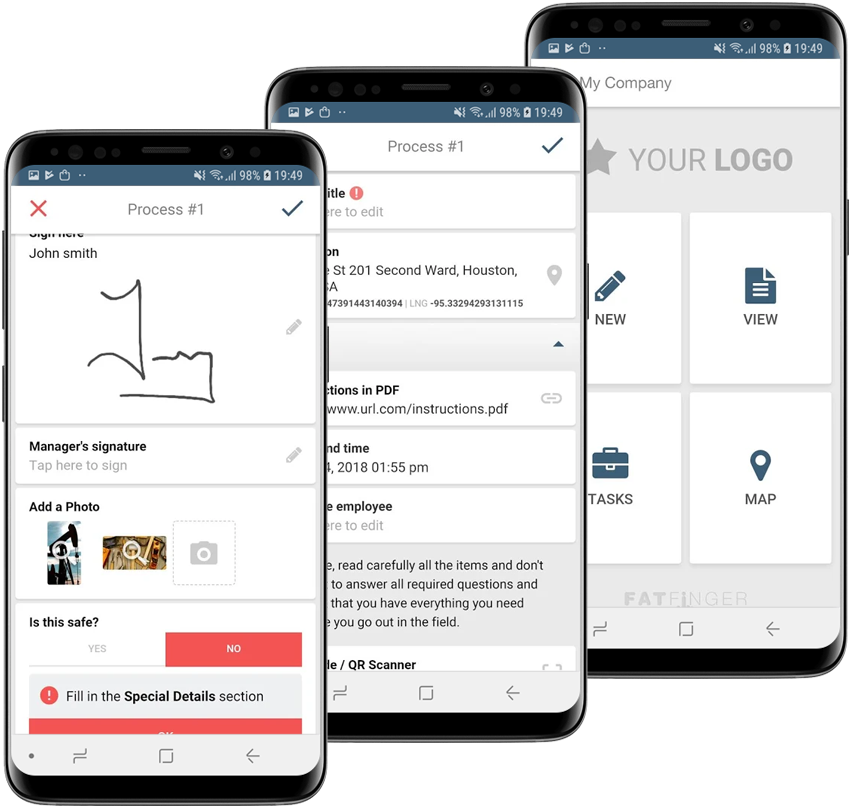

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io

Near-miss reporting for everyone – Anytime and anywhere.

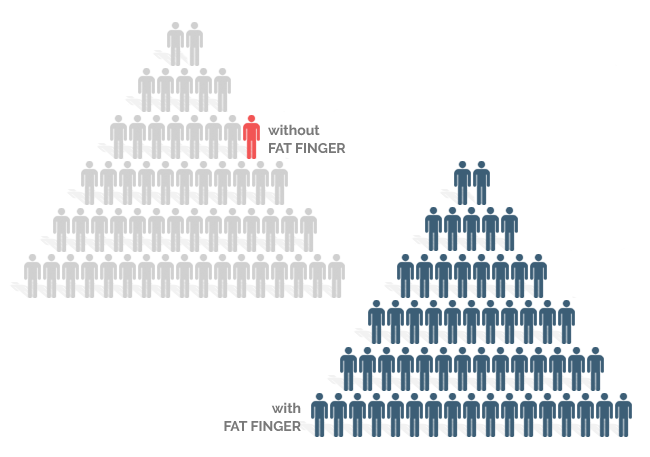

We empower EVERYONE to initiate and create positive change to improve the company’s safety records no matter where you are. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

Data powerhouse – Keeping everything in one place.

Data are stored in the cloud and available in real-time to everyone who needs it. All your up-to-date safety work instructions and training content are available across any device as employees perform the work.

Advanced Analytics- What gets measured, gets managed.

Every single piece of information captured by FAT FINGER users will feed your company analytics in real time. FAT FINGER provides you with valuable insights to help improve your workplace safety. With detailed dashboards, you can quickly identify areas of improvement and track your progress over time.