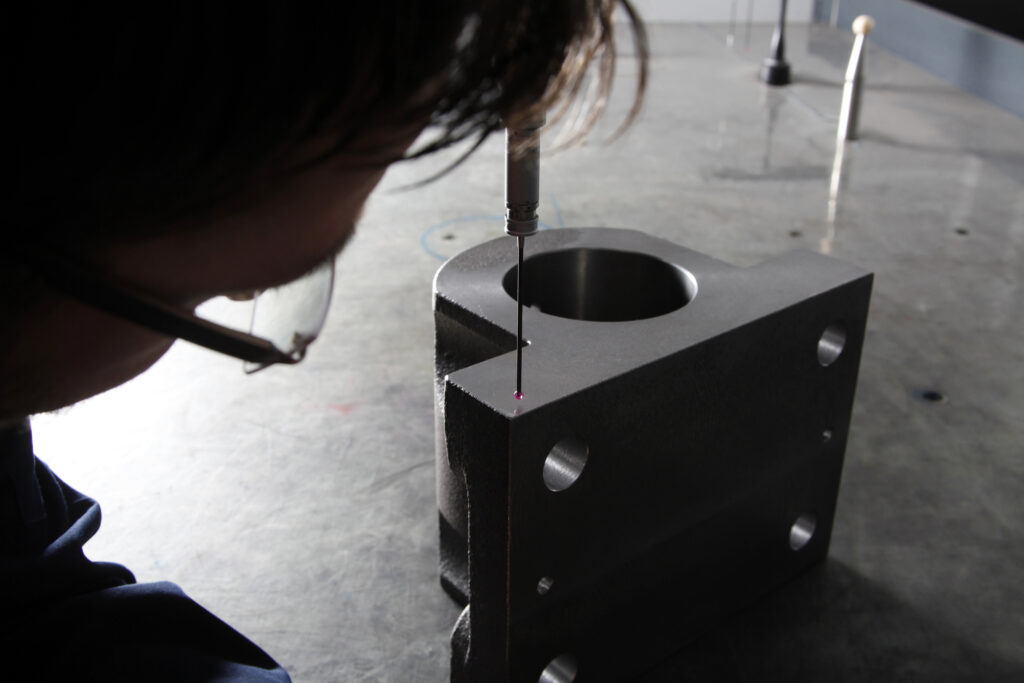

Production quality is a multifaceted strategy that goes beyond simply delivering defect-free products. It is a holistic approach that impacts customer satisfaction, brand reputation, regulatory compliance, operational efficiency, and overall competitiveness.

Manufacturers prioritizing production quality are better positioned for long-term success in the dynamic landscape of industrial manufacturing. This article will explore various facets of why production quality is a non-negotiable aspect of any manufacturing enterprise.

The Role of Technology in Production Quality Assurance

Before we delve into the article, let’s explore how you can improve production quality with FAT FINGER.

Traditional methods of data capture in manufacturing processes often involve manual entry, which is prone to errors and delays.

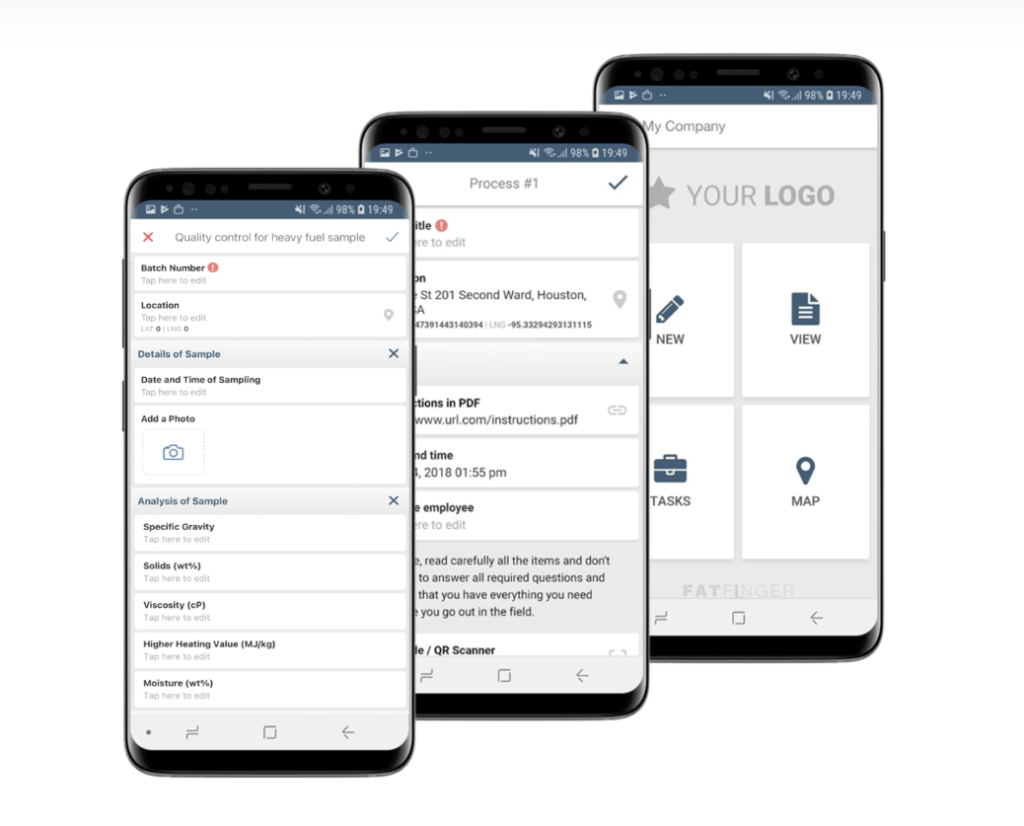

FAT FINGER streamlines this process by providing a user-friendly interface for real-time data capture. With a few taps on a mobile device or tablet, operators can input crucial data at various stages of production, ensuring accuracy and efficiency.

Immediate Issue Identification

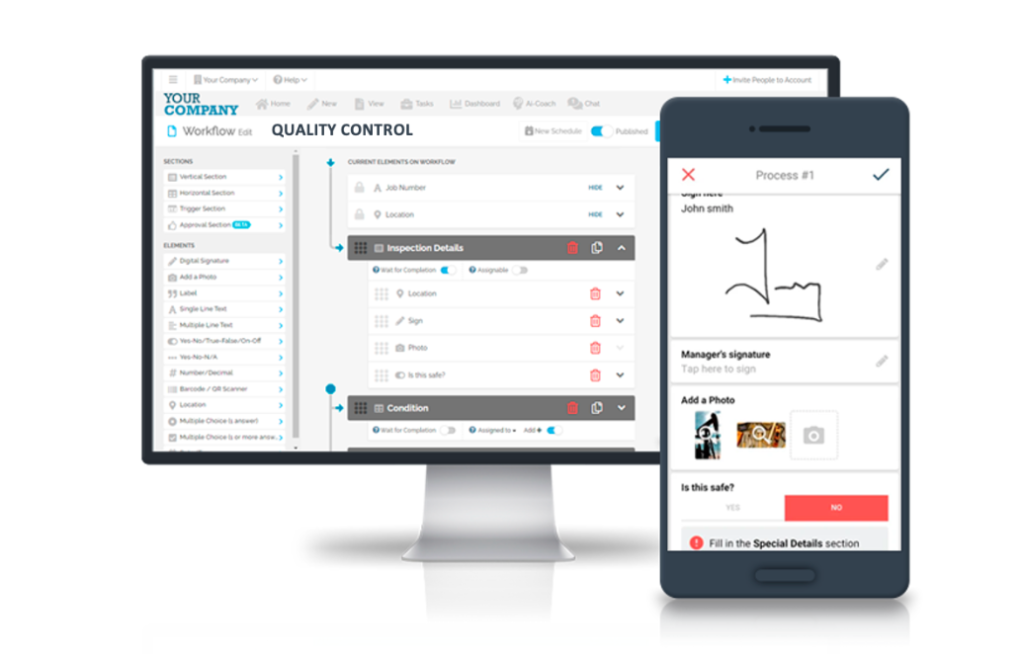

One of the key benefits of FAT FINGER is its ability to facilitate immediate issue identification. In a dynamic manufacturing environment, prompt detection of quality deviations is critical. The app lets workers quickly report discrepancies, defects, or deviations from established standards, triggering swift corrective actions. Your workers can take photos and upload them into the workflow. They can also integrate AR or IoT devices with FAT FINGER, and immediately log in any issues identified.

Ensuring Compliance with SOPs

Standard Operating Procedures (SOPs) form the backbone of quality assurance in manufacturing. With FAT FINGER, you can build SOP checklists or import SOPs documents, making them accessible and seamlessly integrated into your digital workflow. This integration guarantees that every worker follows the specified procedures, minimizing the risk of deviations and ensuring compliance with quality standards.

Enhanced Communication and Collaboration

Effective communication and collaboration are paramount in maintaining high production quality. FAT FINGER facilitates seamless communication between workers, supervisors, and quality control teams. The app enables your team to instantly share information, updates, and alerts, fostering a collaborative environment that contributes to quality assurance.

Real-Time Reporting and Analytics

Accessing real-time reporting and analytics is a game-changer in quality assurance. FAT FINGER provides comprehensive insights into production data, allowing stakeholders to monitor performance, identify trends, and make data-driven decisions. This real-time visibility enhances proactive decision-making, reducing the likelihood of quality issues.

Mobile Accessibility and Flexibility

Manufacturing environments are dynamic, and mobility is critical. FAT FINGER works on mobile, allowing your workers to perform quality assurance tasks anywhere on the production floor or offsite. This flexibility saves time and ensures that quality checks are conducted promptly and efficiently.

Facilitating Continuous Improvement:

Quality assurance is not a static process—it requires continuous improvement. The FAT FINGER app contributes to this ethos by capturing valuable data for analysis. Identifying patterns, trends, and areas for enhancement becomes more accessible, paving the way for ongoing improvements in production quality.

10 Reasons to Improve Production Quality

1. Customer Satisfaction

Observing production quality is paramount for ensuring customer satisfaction. When manufacturers consistently deliver high-quality products, customers experience reliability and performance as promised. This satisfaction fosters brand loyalty and leads to positive word-of-mouth, enhancing the company’s reputation in the market.

2. Brand Reputation and Image

Production quality is intricately linked to a company’s brand reputation. A commitment to quality establishes the brand as trustworthy and reliable.

A positive brand reputation, built on consistently high production standards, attracts more customers and positions the company as a leader in the industry.

3. Compliance with Regulatory Standards

Observing production quality is essential for compliance with regulatory standards and industry-specific requirements. Non-compliance can lead to legal repercussions, fines, and damage to the company’s standing. Adhering to established standards ensures a smooth operation within the regulatory framework and builds stakeholder trust.

4. Cost Reduction through Efficiency

Maintaining high production quality contributes to cost reduction in the long run. Fewer defects mean less rework, lower rejection rates, and minimized wastage of materials. Efficiency in production processes, achieved through stringent quality control measures, leads to substantial savings and improved overall operational performance.

5. Increased Operational Efficiency

Production quality is directly tied to operational efficiency. When quality control measures are effectively implemented, the production process becomes streamlined and more predictable. This, in turn, reduces downtime, enhances productivity, and optimizes resource utilization, contributing to a more efficient manufacturing operation.

6. Competitive Advantage:

In a competitive market, the ability to deliver high-quality products sets a manufacturer apart from its competitors. A reputation for quality becomes a unique selling proposition, attracting customers who prioritize reliability. This competitive advantage is a crucial driver for sustained growth and market dominance.

7. Customer Retention

Beyond attracting new customers, maintaining production quality is crucial for customer retention. Consistent quality builds trust, and satisfied customers are more likely to return for repeat purchases. A loyal customer base is a valuable asset contributing significantly to a company’s revenue and long-term success.

8. Risk Mitigation

Observing production quality helps mitigate risks associated with product failures or recalls. Identifying and addressing quality issues early in production reduces the likelihood of defective products reaching the market. This proactive approach safeguards the company against reputational damage and financial losses.

9. Employee Morale and Engagement

A focus on production quality positively impacts employee morale and engagement. When employees see their efforts contributing to creating high-quality products, it fosters a sense of pride and job satisfaction.

Engaged employees are more likely to commit to maintaining and improving production quality.

10. Innovation and Continuous Improvement:

Observing production quality encourages a culture of innovation and continuous improvement. Companies committed to quality are more likely to invest in research and development, adopt new technologies, and explore innovative manufacturing processes. This commitment to improvement keeps the company at the forefront of industry trends.

Build A Production Quality Checklist With FAT FINGER

FAT FINGER represents a paradigm shift in how technology can enhance quality assurance in industrial manufacturing. Its user-friendly interface, real-time capabilities, and focus on immediate issue identification make it a valuable asset for companies committed to delivering excellence.

By leveraging the power of digital workflows built with FAT FINGER, your manufacturing facility can meet and exceed quality standards, setting new benchmarks for efficiency and reliability in the industry.