Optimizing worker training for effective line changeovers is a critical aspect of manufacturing operations. It not only enhances productivity but also ensures consistent product quality. One tool that is revolutionizing this process is FAT FINGER.

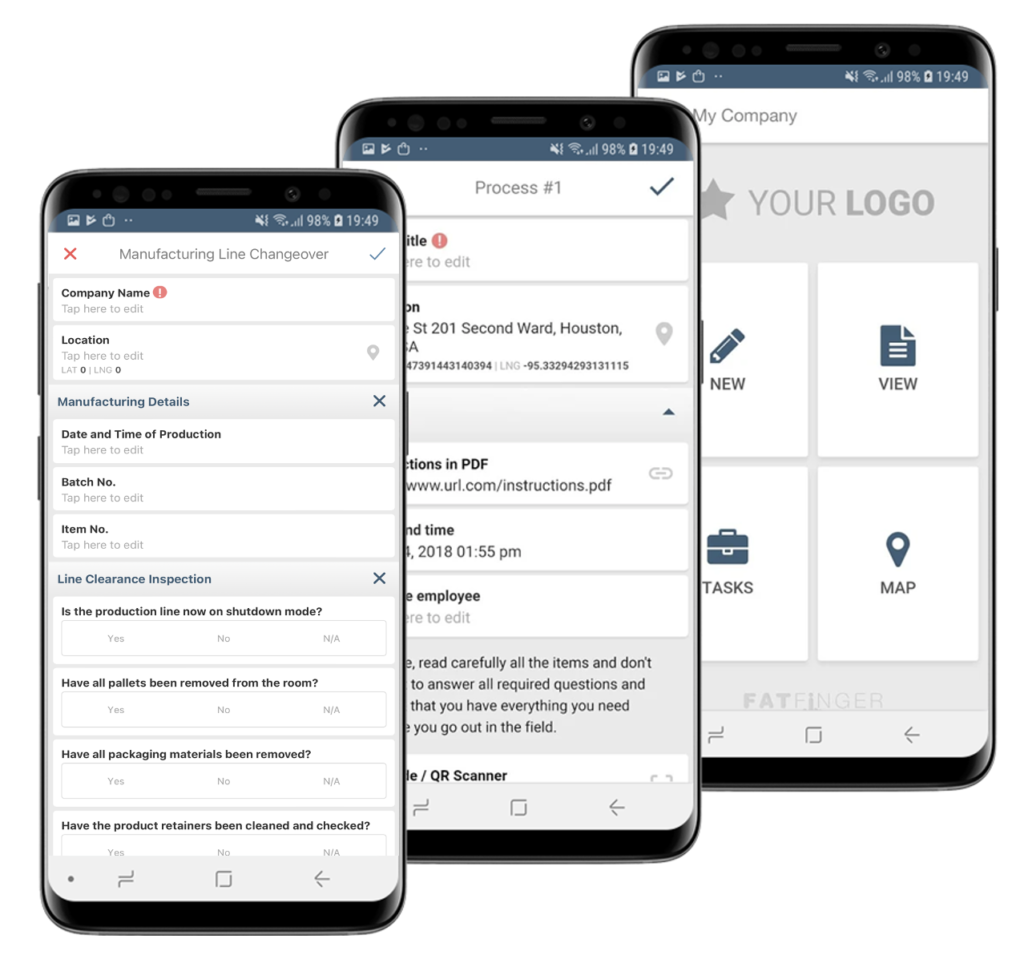

This digital workflow procedure builder empowers front-line teams to do their work correctly every time, by allowing you to build checklists, workflows, and digital procedures that unlock operational excellence. FAT FINGER is a game changer for production line clearance processes, streamlining operations and boosting confidence in production lines. Request a demo today to see how FAT FINGER can transform your Line Changeover process.

Understanding Line Changeovers

Line changeover, also known as line clearance, is the process of verifying that all line changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality. However, the effectiveness of line changeovers largely depends on the training of the workers involved.

Optimizing Worker Training for Effective Line Changeovers

Worker training is a crucial component of successful line changeovers. Here are some strategies to optimize worker training:

- Standardized Training: Ensure that all workers receive the same level of training. This promotes consistency and reduces the likelihood of errors.

- Hands-on Training: Practical, hands-on training is more effective than theoretical learning. It allows workers to gain firsthand experience and understand the nuances of the process.

- Continuous Learning: Regular refresher courses and updates on new procedures or equipment keep workers up-to-date and enhance their skills.

- Use of Digital Tools: Incorporating digital tools like FAT FINGER in training can simplify complex procedures and ensure that every step is followed correctly.

The Role of FAT FINGER in Line Changeovers

FAT FINGER’s features, such as the Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, can be instrumental in facilitating seamless line changeovers. With FAT FINGER, you can build digital line clearance procedures that reduce downtime, improve line efficiency, and increase product quality.

Production Managers who have used FAT FINGER say, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.”

Conclusion

Optimizing worker training for effective line changeovers is crucial for manufacturing operations. It not only enhances productivity but also ensures consistent product quality. Incorporating digital tools like FAT FINGER in the training process can simplify complex procedures and ensure that every step is followed correctly. With its array of features, FAT FINGER can help streamline your production line clearance process, reduce downtime, improve line efficiency, and increase product quality. Sign up for FAT FINGER today and transform your line changeover process.

Ready to optimize your worker training for effective line changeovers? Start now by visiting FatFinger and discover the best strategies and tools to enhance your production line efficiency. Don’t wait, improve your operations today!