Facility operations management is a complex task that requires meticulous planning, coordination, and execution. One of the key aspects of this process is work order management, which involves creating, assigning, tracking, and closing work orders. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures that unlock operational excellence.

In this article, we will delve into how you can develop a work order management system for your facility operations using FAT FINGER. But first, let’s understand why you need such a system.

Why You Need a Work Order Management System

Work order management systems are crucial for facility operations for several reasons. They help streamline processes, improve efficiency, reduce errors, and enhance productivity. Without a proper system in place, managing work orders can become chaotic and lead to missed deadlines, poor quality of work, and increased costs. Therefore, having a robust work order management system is not just a luxury but a necessity for any facility operation.

Introducing FAT FINGER

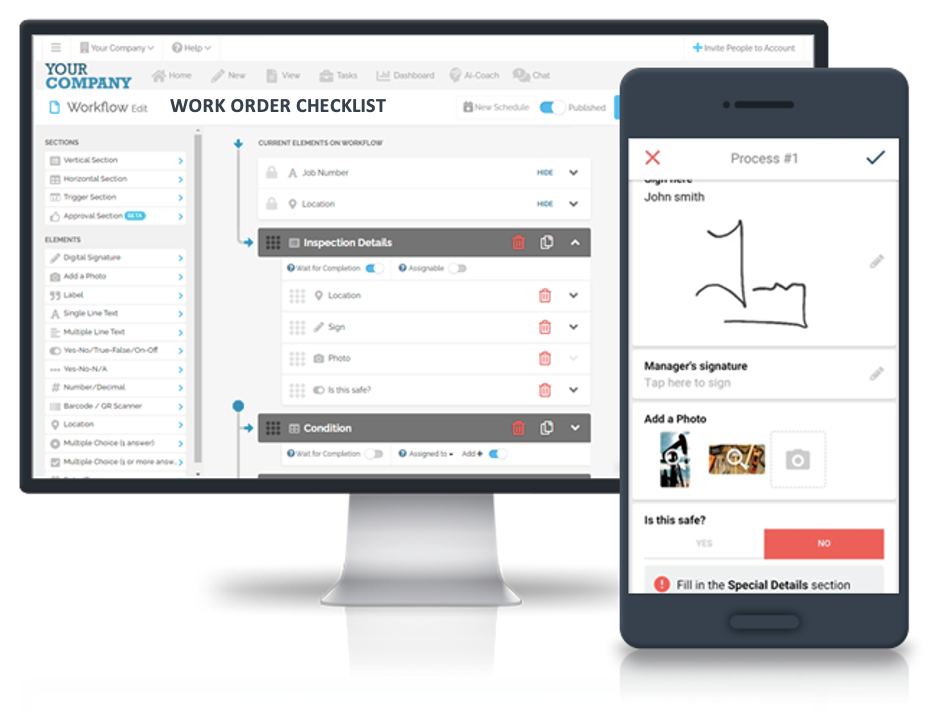

FAT FINGER is a powerful tool that can help you build a comprehensive work order management system. It offers a range of features that make the process of creating, assigning, tracking, and closing work orders a breeze. Some of these features include:

- Easy-to-use interface

- Real-time tracking

- Automated workflows

- Customizable templates

- Instant notifications

- Advanced analytics

With these features, FAT FINGER provides a complete solution for your work order management needs. Now, let’s see how you can use FAT FINGER to develop your work order management system.

Developing a Work Order Management System with FAT FINGER

Developing a work order management system with FAT FINGER involves a few simple steps:

- Create a workflow: FAT FINGER allows you to create a workflow that suits your facility operations. You can customize the workflow to match your specific needs and requirements.

- Assign tasks: Once the workflow is created, you can assign tasks to your team members. FAT FINGER’s real-time tracking feature allows you to monitor the progress of each task.

- Track progress: FAT FINGER provides real-time updates on the status of each work order. This helps you keep track of the progress and ensure that all tasks are completed on time.

- Close work orders: Once all tasks are completed, you can close the work order. FAT FINGER’s automated workflows ensure that all tasks are completed and no work order is left open.

By following these steps, you can develop a robust work order management system that enhances your facility operations.

Case Study: Streamlining Work Order Management With FAT FINGER

A leading facility operations company, was struggling with managing their work orders. They were using a manual system that was time-consuming, error-prone, and inefficient. After implementing FAT FINGER, they were able to streamline their work order management process, reduce errors, and improve productivity. The real-time tracking feature allowed them to monitor the progress of each work order and ensure timely completion. The automated workflows eliminated the need for manual intervention, reducing the chances of errors. As a result, the company was able to enhance their operational efficiency and improve their bottom line.

Conclusion

Work order management is a critical aspect of facility operations. Without a proper system in place, it can lead to chaos and inefficiency. FAT FINGER provides a comprehensive solution for work order management, with features like real-time tracking, automated workflows, and customizable templates. By using FAT FINGER, you can develop a robust work order management system that enhances your facility operations and improves your bottom line.

Ready to transform your work order management process? Build a digital workflow for free on FAT FINGER or schedule a demo to see how it can revolutionize your facility operations.