Operational downtime is a nightmare for any business. It can lead to lost productivity, decreased customer satisfaction, and significant financial losses. One of the most effective ways to prevent this is through preventive maintenance. This article will delve into the importance of preventive maintenance and how it can significantly reduce operational downtime. We will also introduce you to FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build predictive maintenance digital workflows to ensure problems are gone even before they start. So, why wait? Request a demo today and see how FAT FINGER can revolutionize your maintenance procedures.

Preventive Maintenance and Operational Downtime

Preventive maintenance plays a crucial role in reducing operational downtime in the following ways:

- It helps identify potential issues before they become serious problems.

- It extends the lifespan of your equipment, reducing the need for replacements.

- It improves the efficiency and reliability of your equipment.

- It reduces the risk of unexpected breakdowns that can lead to operational downtime.

By carrying out preventive maintenance, companies can enhance the lifespan and efficiency of their equipment, saving time and reducing costs in the long run. It can help prevent unexpected breakdowns, which can lead to costly repairs and prolonged downtime that could negatively impact productivity and revenue.

Furthermore, preventive maintenance can also improve safety in the workplace. Regular checks can help to identify any safety risks that may be arising due to faulty or aging machinery. This can prevent accidents and injuries, promoting a safer and healthier work environment.

Moreover, preventive maintenance enhances equipment reliability. When machinery is consistently maintained, it is less likely to fail, thus ensuring smoother operations and minimizing any potential delays or interruptions. This can lead to improved customer satisfaction, as the company can reliably meet its obligations and deadlines.

Thus, preventive maintenance is not just a cost-saving measure, but also a proactive strategy that can lead to improved efficiency, safety, reliability, and overall operational success. It plays a crucial role in reducing operational downtime, making it an indispensable part of any business operation.

The Role of FAT FINGER in Preventive Maintenance

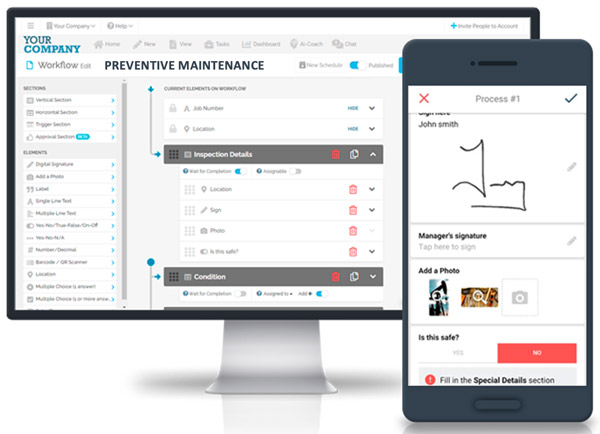

FAT FINGER is a game-changer in the world of preventive maintenance. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER takes preventive maintenance to a whole new level.

Case Study: The Power of Preventive Maintenance

Preventive maintenance can reduce the likelihood of equipment failure by 30% to 50%. This not only saves money on repair costs but also significantly reduces operational downtime.

Predictive Maintenance: The Future of Preventive Maintenance

Predictive maintenance is an advanced form of preventive maintenance that uses data and technology to accurately determine when maintenance needs to be completed to prevent costly breakdowns. It collects data from a facility’s various components and uses it to determine when parts need maintenance. It can also use algorithms or Artificial Intelligence (AI), if necessary. Predictive maintenance can help save time and money, improve efficiency in the facility, and help ensure that safety standards are adhered to throughout the lifecycle of all machines.

FAT FINGER and Predictive Maintenance

With FAT FINGER, you can build predictive maintenance digital workflows that take the guesswork out of maintenance. By leveraging data and AI, FAT FINGER can help you accurately predict when maintenance is needed, preventing costly breakdowns and reducing operational downtime.

Conclusion

Preventive maintenance is critical in reducing operational downtime. It helps identify potential issues before they escalate, extends the lifespan of your equipment, and improves efficiency. With the advent of predictive maintenance, businesses can now leverage data and AI to accurately predict when maintenance is needed, further reducing operational downtime. FAT FINGER is at the forefront of this revolution, providing businesses with the tools they need to build predictive maintenance digital workflows. So, why wait? Create a predictive maintenance workflow for free on FAT FINGER or schedule a demo today and see how FAT FINGER can revolutionize your maintenance procedures.

Discover the critical importance of preventive maintenance in reducing operational downtime. Don’t let unexpected breakdowns disrupt your business. Learn how to implement effective preventive measures and ensure smooth operations. Schedule a Demo today and take the first step towards a more efficient and reliable operational system.