As industries strive to achieve operational excellence, the integration of Total Quality Management (TQM) in industrial operations has become a critical factor. One tool that is revolutionizing this integration is FAT FINGER. This digital workflow procedure builder empowers front-line teams to do their work correctly every time, unlocking operational excellence. With FAT FINGER, you can build checklists, workflows, and digital procedures that ensure safety and preventive measures are everyone’s responsibility. Request a demo today to see how FAT FINGER can transform your industrial operations.

Understanding Total Quality Management (TQM)

Total Quality Management (TQM) is a management approach that originated in the 1950s and has steadily become more popular since the early 1980s. TQM aims at ensuring all organizational functions (marketing, finance, design, engineering, and production, customer service, etc.) focus on meeting customer needs and organizational objectives.

Integrating TQM in Industrial Operations

Integrating TQM in industrial operations involves a strategic approach that focuses on improving the quality of an organization’s outputs, including goods and services, through continual refinement in response to continuous feedback. This integration can be achieved effectively with the help of digital tools like FAT FINGER.

How FAT FINGER Facilitates TQM Integration

FAT FINGER offers a range of features that facilitate the integration of TQM in industrial operations. These include:

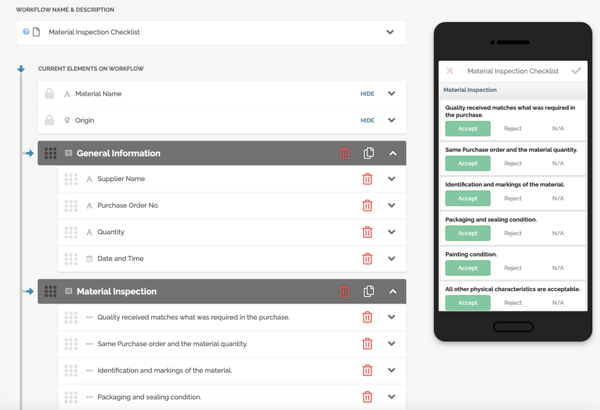

- Drag & Drop Workflow Builder

- Mobile & Desktop Workflows

- Dashboards

- Integrations

- Augmented Reality

- Connect IoT Devices

- Artificial Intelligence Coaching

Case Studies: TQM Integration with FAT FINGER

Here are some powerful checklists you can build with FAT FINGER to boost operational efficiency and integrate TQM in your industrial operations:

1. Material Inspection

Ensure the highest quality standards of your products with a digital material inspection. With our revolutionary workflow, materials can be inspected quickly and accurately with less reliance on manual labor. Defects can be identified early in the production process before they become too costly.

2. Quality Control

See to it that what your customers get presents the best of your brand. Reach maximum production potential with customized automated workflow. Smart workflow enables a seamless transition from paperwork processes to digital ones in minutes.

3. Shift Handover

Transform the way your frontline shift management works with a checklist that keeps your team moving. Modernize your shift transition and watch the savings skyrocket. Automate tedious, monotonous tasks quickly – and keep your entire team in the loop.

4. Facility Inspection

Ensure your facility keeps running without a hitch with this effective facility inspection workflow. Streamline your checklists, SOPs and inspections with our intuitive workflow solution.

5. Line Changeover

Get the most out of your production by seamlessly transitioning between processes with our line changeover solution. Cutting down tedious tasks like manual reporting and quality monitoring is now easier than ever.

6. Electronic Field Ticket

Electronic tickets have ushered in a new era of engineering. Upgrade your ticketing system and save big. Cut out tedious tasks and boost your team’s productivity with automated field reporting, workforce scheduling, and invoicing.

Conclusion

Integrating Total Quality Management (TQM) in industrial operations is a strategic move towards achieving operational excellence. With digital tools like FAT FINGER, this integration becomes seamless, efficient, and effective. By building powerful checklists and workflows, you can ensure safety, quality, and productivity in your industrial operations. Start building your safety checklist with FAT FINGER today and unlock the potential of your operations.

Ready to elevate your industrial operations to the next level? Integrate Total Quality Management (TQM) today and witness a significant improvement in your operational efficiency and product quality. Don’t wait, Request A Demo now and start your journey towards excellence.