In the fast-paced world of manufacturing, efficiency is key. One area where efficiency can be significantly improved is in line changeovers. This process, also known as line clearance, involves verifying that all Line Changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality. However, achieving these benefits requires the right tools and equipment. This is where FAT FINGER comes in.

About FAT FINGER

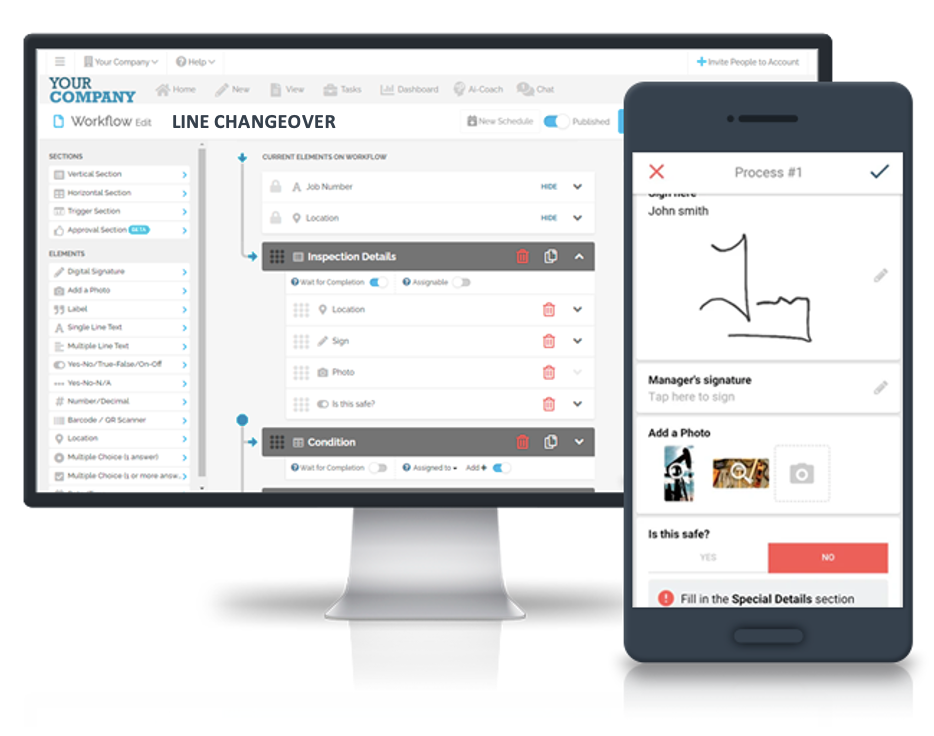

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER allows you to build digital line clearance procedures to facilitate seamless line changeovers. As one Production Manager puts it, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.” Request a demo today to see how FAT FINGER can revolutionize your line changeover process.

How Innovative Tools and Equipment Streamline Line Changeovers

Line changeovers can be complex and time-consuming, but with the right tools and equipment, they can be streamlined for maximum efficiency. Here are some ways in which innovative tools and equipment can help:

- Automated workflows: With FAT FINGER’s drag & drop workflow builder, you can create automated workflows that guide your team through the line changeover process step by step, reducing the risk of errors and oversights.

- Real-time dashboards: FAT FINGER’s dashboards provide real-time visibility into your line changeover process, allowing you to monitor progress and identify bottlenecks in real time.

- Integration with other systems: FAT FINGER integrates with your existing systems, allowing you to leverage your existing data and technology investments.

- Augmented reality: FAT FINGER’s augmented reality feature allows your team to visualize the line changeover process in a whole new way, making it easier to understand and follow.

- IoT device connectivity: With FAT FINGER, you can connect your IoT devices to your line changeover process, allowing you to automate tasks and collect data in real time.

- Artificial intelligence coaching: FAT FINGER’s AI coaching feature provides your team with real-time guidance and feedback, helping them to improve their performance over time.

The Impact of Streamlined Line Changeovers

Streamlining your line changeover process with innovative tools and equipment like FAT FINGER can have a significant impact on your bottom line. According to a study by the Aberdeen Group, companies that have streamlined their line changeover process have seen a 20% increase in overall equipment effectiveness, a 12% reduction in downtime, and a 10% increase in production capacity. These improvements can translate into significant cost savings and increased profitability.

Conclusion

In conclusion, streamlining your line changeover process with innovative tools and equipment like FAT FINGER can significantly improve your efficiency, reduce downtime, and increase product quality. With features like automated workflows, real-time dashboards, integration with other systems, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER provides a comprehensive solution for streamlining your line changeover process. Sign up for FAT FINGER today to start reaping the benefits of streamlined line changeovers.

Discover the latest in tools and equipment innovations for streamlining line changeovers. Enhance your productivity and efficiency today. Visit FatFinger to learn more.