As the world continues to grapple with the challenges of Energy Production and consumption, the need for efficient and sustainable solutions has never been more critical. One such solution is Data Analytics, a powerful tool that is revolutionizing the energy sector. This article explores the role of Data Analytics in optimizing Energy Production, with a particular focus on how FAT FINGER, a digital workflow procedure builder, is contributing to this transformation.

Understanding the Power of Data Analytics

Data Analytics involves the use of advanced techniques and tools to analyze large volumes of data and extract valuable insights.

In the context of Energy Production, data analytics can play a crucial role in optimizing operations and increasing overall efficiency. It allows energy companies to understand the patterns and trends in their operations, identify potential problems before they escalate, and make informed decisions based on factual data. For instance, predictive analytics can provide foresight into equipment maintenance needs, thereby preventing unexpected machinery breakdowns that could lead to operational disruptions.

Moreover, data analytics can help improve efficiency by providing insights into energy usage patterns and identifying areas where energy is being wasted. With this information, companies can implement measures to reduce wastage and improve energy conservation, resulting in substantial cost savings. For example, data analytics could reveal that a particular process is consuming more energy than necessary, prompting the company to investigate and rectify the issue.

Furthermore, data analytics can also help reduce costs. By identifying inefficiencies, predicting maintenance needs, and preventing operational disruptions, companies can avoid unnecessary expenses. Additionally, through predictive analytics, companies can forecast energy demand and adjust their production accordingly to minimize waste and reduce costs.

How Data Analytics Optimizes Energy Production

Data Analytics plays a crucial role in optimizing Energy Production in several ways:

- It enables energy producers to predict demand and adjust their production accordingly.

- It helps identify inefficiencies in the production process and suggests ways to improve them.

- It facilitates the integration of renewable energy sources into the grid.

- It aids in predictive maintenance, reducing downtime and increasing productivity.

The Role of FAT FINGER in Energy Production Optimization

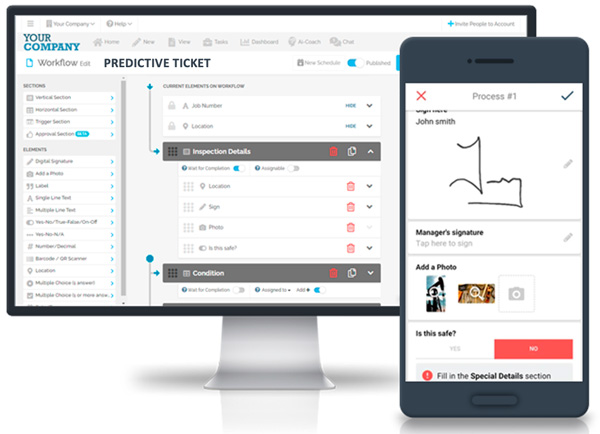

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. FAT FINGER’s features, such as its drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, and artificial intelligence coaching, make it an invaluable tool in the energy sector.

Case Study: FAT FINGER in Action

One example of FAT FINGER’s impact in the energy sector is its role in predictive maintenance. By integrating IoT devices and using Data Analytics, FAT FINGER can predict when a piece of equipment is likely to fail and schedule maintenance before it happens. This reduces downtime, increases productivity, and saves costs.

Conclusion: The Future of Energy Production is Data-Driven

The role of Data Analytics in optimizing Energy Production is clear. By providing valuable insights into demand, Efficiency, and maintenance, Data Analytics can help energy producers optimize their operations, reduce costs, and contribute to a more sustainable future. Tools like FAT FINGER, with its powerful features and user-friendly interface, are leading the way in this data-driven revolution.

Are you ready to unlock the power of Data Analytics in your Energy Production? Sign up for FAT FINGER or request a demo today to start your journey towards operational excellence.